MOVE-T Liquid Dairy Analyzer

Precision in every drop

Discover the MOVE-T

The analysis of milk and dairy products is essential for ensuring quality, safety, and compliance with industry standards. Fourier Transform Near Infrared (FT-NIR) technology is renowned for its rapid, non-destructive testing, ensuring precise and repeatable analysis of fat, protein, lactose, and total solids in dairy products.

The new MOVE-T is a compact FT-NIR benchtop analyzer focusing on liquid analysis from raw milk to liquid finished products, intermediates, and premixes.

- Advanced FT-NIR Technology: Provides precise and reliable analysis.

- Wearless Quartz Flow Cell: Offers maintenance-free durability.

- 2-in-1 Sample Handling: Facilitates efficient sample processing.

- Automated Cleaning: Consistent, dependable results every time.

Need more info?

Innovative 2-in-1 System

The 2-in-1 system of the MOVE-T is designed to streamline your workflow. It allows for automated, product dependent handling, enhancing efficiency and precision in your processes. The dual system can switch software controlled between a powerful homogenizer and a peristaltic pump for sample treatment and transport, depending on the product. Unlike conventional FT-IR milk analyzers, the MOVE-T excels in processing even the most viscous liquid dairy products with ease.

The MOVE-T offers unparalleled flexibility, ensuring consistent sample preparation and reducing manual intervention. Whether you need homogenization or straightforward pumping, the MOVE-T adapts seamlessly to your needs, ensuring optimal results every time.

Why homogenize Raw Milk before Analysis?

The homogenization of raw milk results in the breakdown of fat globules into smaller, uniformly distributed particles, preventing the formation of a cream layer on top. This process ensures the milk sample is consistent, which is essential for accurate and reproducible analysis results.

Furthermore, homogenized milk is more stable, reducing the likelihood of separation during analysis, which helps in obtaining reliable measurements.

When to use the Peristaltic Pump

Unlike raw milk, other types of milk and liquid dairy products do not require homogenization for analysis. The measurement cell with 1.000µm path length accomodates even for viscous samples like cream and ice cream premixes or liquid products with additives or crystal sugar.

Using the peristaltic pump only, without the homogenization step, will also extend maintenance intervals as well as the overall homogenizer’s lifespan.

Applications

Extend the capabilities of the MOVE-T analyser with our versatile application packages. These pre-calibrated packages are designed for accurate analysis of a wide range of products, from raw milk to various derivatives and finished products. They include robust calibration methods for analysing key parameters such as total solids, fat, protein, lactose, and salt, with additional parameters for other components depending on the product.

Our calibration methods are adaptable and can be locally enhanced to meet your specific needs. All method developments and validation procedures adhere to the stringent ISO 21543 IDF 201:2020 guidelines, ensuring maximum reliability.

Furthermore, our team of experts continuously updates these methods to incorporate the latest advancements in technology, providing you with cutting-edge tools for precise and efficient analysis. This ensures that your MOVE-T analyzer remains at the forefront of industry standards, delivering consistent and reliable results every time.

Frequently Asked Questions

Key features of the MOVE-T to ensure robustness and seamless integration into your quality control process include:

- Precise Temperature Control: The flow cell temperature is monitored and regulated via an infrared sensor embedded inside the heating block, ensuring consistent measurement conditions.

- Autogain Functionality: As with the TANGO series, the MOVE-T supports “Autogain”, enabling automatic optimization for varying product matrices without manual adjustment.

- Long-life Light Source: The sealed optical system is equipped with a high-intensity light source offering a mean time to failure (MTTF) of 3 years, ensuring long-term operational stability.

- Automated Background Measurement: An integrated mechanism allows for background measurements with a fixed-position flow cell, eliminating the need for manual intervention.

These design elements contribute to a robust, user-friendly system that delivers reliable and reproducible results over extended periods of operation.

The MOVE-T for liquid dairy products and can analyze a wide range of samples, including:

- Raw milk & processed milk

- Fermented milk products

- Cream-based products

- Condensed & evaporated milk

- Whey and protein products

- Milk drinks and premixes

- Liquid ice cream

- Plant-based dairy alternatives

This flexibility makes it suitable for various stages of dairy production, from raw milk to finished products.

We know that reliable analyzers are essential to the dairy industry. This is why all our method development and validation procedures with the MOVE-T and other dairy analyzers based on FT-NIR spectroscopy are according to the ISO 21543 IDF 201:2020 guidelines, giving you peace of mind.

Moreover, Bruker Optics itself is ISO certified. The company holds certifications for ISO 9001, ISO 13485, ISO 14001, and ISO 50001, ensuring that their products meet high standards of quality, environmental management, and energy management.

In addition to the MOVE-T, Bruker offers various other analyzers for the dairy market based on FT-NIR technology:

- The MPA III Dairy Analyzer sets a new standard for analyzing both liquid and solid samples, featuring a software-controlled Liquid Sampling Module, homogenizer, and peristaltic pump to ensure precise and repeatable results across a wide range of dairy products.

- The TANGO analyzer, known for its simplicity and reliability, uses FT-NIR spectroscopy to provide accurate analysis of cheese and other dairy products, making it ideal for routine quality checks with its user-friendly interface and robust design.

- The BEAM, an automated system, streamlines the analysis process by reducing manual intervention and increasing throughput, effectively monitoring and controlling production processes to ensure consistent product quality.

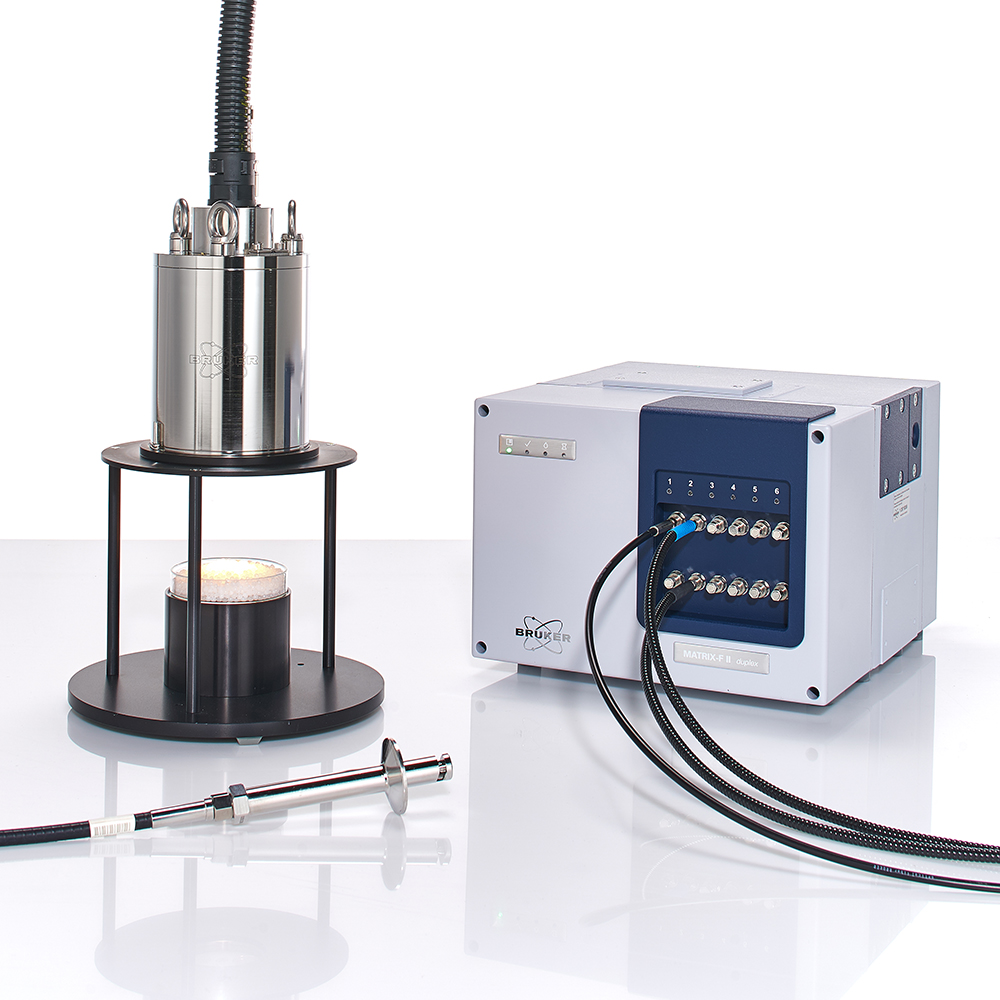

- The MATRIX-F II, a high-performance FT-NIR analyzer, is designed for in-line process control, offering real-time monitoring to optimize production efficiency and maintain high standards of product quality.

Collectively, these analyzers empower the dairy industry to maintain quality, improve efficiency, and ensure product consistency.