Interior and Exterior

NMR for Automotive Paint and Tires

Bruker’s innovative solutions have found application in a huge array of industries, including the field of paint and tires. The industry’s most prominent paint companies use Bruker NMR technology in research and development, on product composition, and in quality control.

Tracing Inclusions in Sealing Rubber with FT-IR Microscopy

Todays cars are full of plastic and rubbers that provide either protection, design or functional elements. In those cases, failure and damage analysis is the main application of FT-IR microscopy, as it offers quick and clear answers to basic root cause questions. It easily analyzes:

- Inclusions and Residues

- Contaminations

- Aging and withering effects

- Chemical reaction products

Identifying an Unknown Residue on a Plastic Car Bumper via FT-IR

As already mentioned, you don't have to search long to find plastic parts in the automotive industry. Injection molded parts are mass produced and therefore untreated causes of damage can very quickly cause very high costs. It is therefore crucial to understand damage and failures as quickly and as well as possible.

FT-IR microscopy and spectroscopy is a fundamental and powerful tool for polymer samples. In this example, the aim was to investigate an off-white, sticky contamination on a carbon black filled polymer. Such use cases are very common and whenever plastic parts or polymers suffer damages or defects, an infrared microscope is the go-to-solution.

Raw Material Identification and Verification by Infrared Spectroscopy

In the manufacturing industry, raw material analysis is the foundation of an optimal production process. Sudden and unexpected changes in the specifications of a raw material provider can cause severe damages. Especially in the automotive sector, where the supply chains are long and complicated.

Infrared spectroscopy is a universal tool to clearly identify the chemical identity of almost any raw material. It analyzes polymers, chemicals, oils, pigments, fillers, inorganics and even natural products like wood!

It is characterized by simplicity and speed. The analyses with infrared (IR) can be carried out by any personnel and provide confirmation of the raw material within one minute.

Tire and Rubbers Quality Control by FT-IR Spectroscopy

The analysis of defects and inclusions on rubber samples like tires can be very challenging since often the defects are microscopically small or show a very low contrast. With FTIR microscopy, even very small contaminations with a very low visual contrast can be visualized and identified.

The image shows the visual and the chemical image of a contamination on a rubber sample. Besides the contamination that is also evident on the visible image the chemical image shows much more information and reveals contaminations that are invisible to the unaided eye. Of course, it is also possible to identify the chemical nature of the contamination, in this case PTFE and polyamide.

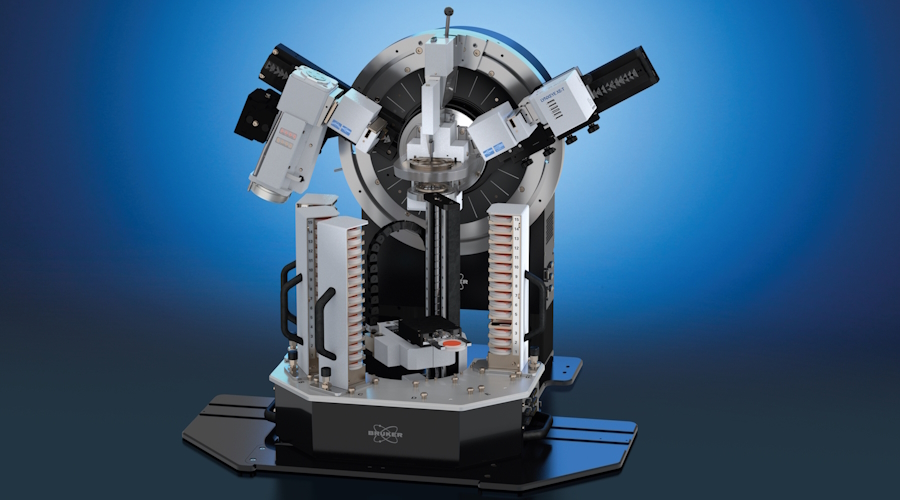

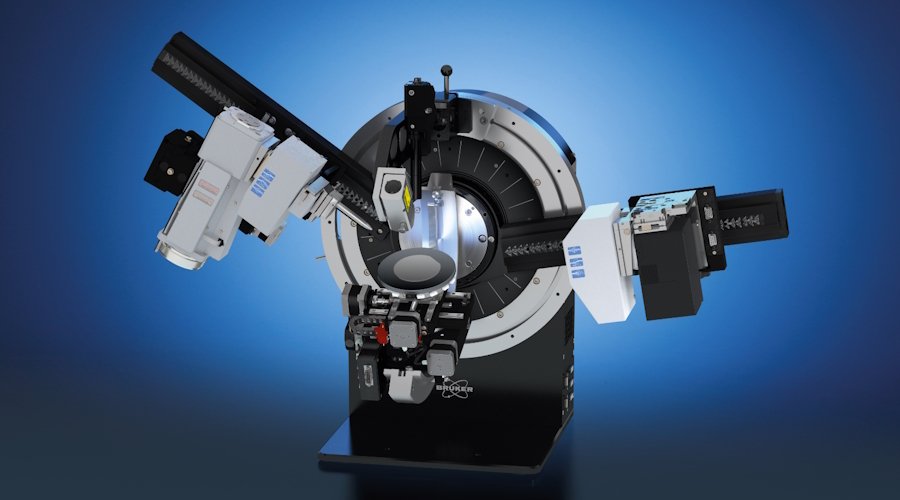

Sheet Metal and Paint Analysis with XRD

X-ray Diffraction (XRD) is used to analyze both the sheet metal and paint that makes up the exterior of automobiles. A series of coatings is often applied to sheet metal to protect it from corrosion and increase paint adherence. In addition, stress and texture are induced in the metal which can change the way in which it is formed during manufacture and the way it behaves in collisions. The paint that is applied is also analyzed with XRD verify pigments and check for impurity phases which may lead to premature failure.