Positive Material Identification (PMI)

Highlights on Positive Material Identification (PMI)

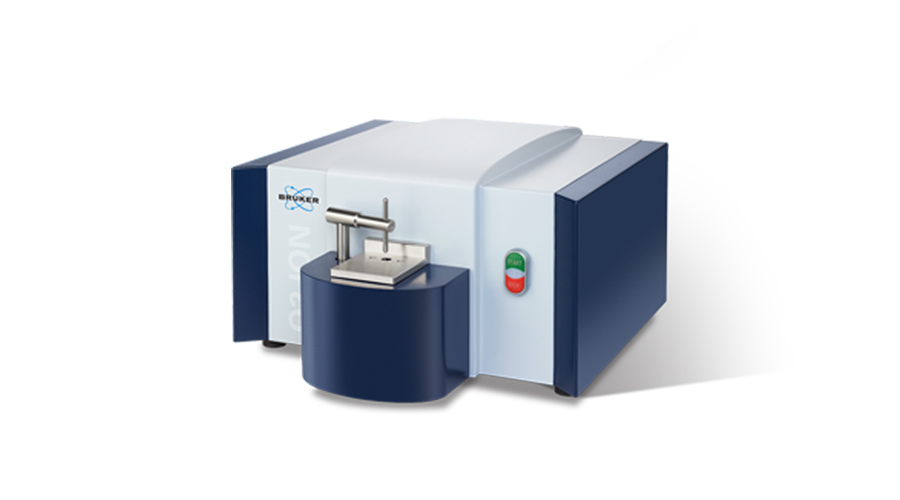

Positive Material Identification (PMI) is a fast and non-destructive testing (NDT) method for verifying the chemical composition of metals and alloys. PMI can be used to verify that supplied materials conform to the proper standards and specifications. Handheld X-ray fluorescence is the most common PMI method, it is portable, cost-effective and allows PMI to be performed in the field, production floor or in the lab.

What is PMI?

Positive material identification (PMI) is an essential non-destructive testing (NDT) method utilized to verify that supplied materials conform to the proper standards and specifications. Specifically, PMI is used to confirm that the chemical composition of the metallic parts has the correct percentage of key elements, this ensures that material properties such as corrosion resistance meets the requirements.

The PMI is utilized for quality control and safety compliance and is an integral part of both production and asset integrity management across many industries including oil and gas, power generation, chemical, pharmaceutical, nuclear, aerospace, and metal fabrication.

The material testing can be performed on-site before the parts go into the production process or for final products. Retroactive PMI is used to test in-service process equipment and piping systems. PMI can be utilized on a variety of part sizes – from large complex parts to things as small as the weld fill material or small fasteners.

Handheld X-ray Fluorescence (XRF) is the most common PMI method and the portability of the hand-held equipment allows to perform PMI on-site at the production plant or factory floor. The handheld XRF instrument scans the material and provides chemical composition and alloy grade name.

Importance of PMI and Recommended Practices

One of the most common causes of industrial accidents is failures in mechanical integrity. Examples of this include rupture of pressurized systems, stress corrosion cracking, flow accelerated corrosion especially in power/nuclear plant technology, and insufficient strength of welded joins.

Positive material identification can prevent potential product failure in manufacturing. At oil and gas, power generation and pharmaceutical plants, pre-service and in-service inspection of critical components and welds with PMI can prevent breakdown and its potentially costly and dangerous consequences.

PMI testing means that companies can make sure that every single part in their system meets specifications, critical replacement parts are the right alloy grade and all new materials are exactly what they should be. This important step can be the key difference between seamless operations and catastrophic safety failures.

PMI is a widely adopted non-destructive testing method and there are several standards and recommended practices for it. The American Petroleum Institute recommended practice, API RP 578 – Material Verification Program for New and Existing Alloy Piping Systems, provides the guidelines for a quality assurance system to verify the alloy components. Another widely used PMI guide is ASTM E1476 is a Standard Guide for Metals Identification, Grade Verification, and Sorting. Both of these documents cover the use of the handheld XRF and other applicable techniques.

Positive Material Identification Uses

- Ensure that products and components have been manufactured using the correct alloy

- Find potentially mixed-up alloys

- Ensure material conforms to the correct standard and specification

- Ensure welded components have used the correct filler material

- Failure Analysis PMI – it is vital that the cause is identified and resolved to avoid repeat failures

- Ensure compliance with local government and legal requirements

- Reduce risk of company liability with documented safety standards

Related applications: