WLI Semi Metrology

Advanced White Light Interferometry (WLI) Technology

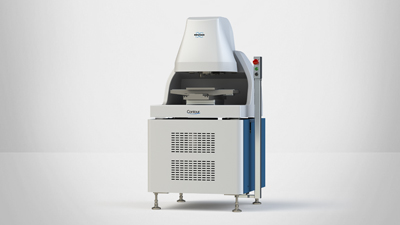

Today’s most advanced WLI profilers provide robust metrology-based inspection for advanced packaging, covering within one measurement all the key applications. When integrated with an automated wafer handler, metrology control and SEC-GEM compatibility, a WLI profiler will boost yield and drive process optimization, all with a minimized footprint in cleanroom-constrained spaces.

Besides covering a wide range of topology using a single measurement head with a unique optical column, Bruker's WLI profilers provide another unique capability: vertical resolution that is both independent from the magnification/objective used and operates at sub-nanometer-levels. Advanced packaging characterization benefits greatly from these characteristics. WLI opens up the opportunity for defect review on interconnect layers with dense bump arrays or bump recesses, capturing large fields of view while maintaining vertical resolution.

The same applies for depth measurements of through silicon vias (TSV) before filling, where 0.1% precision is required to match stringent tolerances but for which low magnifications are required to collect the light reflected on the bottom of the vias. High confidence in vertical resolution also boosts performances of regular planar CD metrology, such as width and spacing of the redistribution layer (RDL) or offset calculations for overlays (OVL) between successive layers in 3D integration structures. In die stacking or die-to-wafer hybrid bonding, PSI mode, together with stitching, helps to accurately capture the full die flatness with micrometer lateral resolution and nanometer reproducibility. Thus, chemical mechanical polishing (CMP) can be optimized upon specific die layouts.

Support

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.