In Operando Nanomechanics

Environmental Control: Temperature, Humidity, and Atmosphere

Bruker’s In Operando environmental testing suite enables nanomechanical and nanotribological characterization of materials in their working environment across a wide range of temperatures, working gases, humidity, and strain rates. This provides researchers the fundamental material performance parameters that are directly applicable to engineering solutions. Typical nanomechanical materials testing is often done in highly controlled laboratory conditions that often do not correspond to the desired working conditions. Oftentimes, extrapolation of a material’s properties, kinetics, and chemical behavior from near ambient temperatures is not valid. The ability to accurately measure and map nanoscale mechanical properties at temperatures from -120°C to more than 800°C, and across multiple working conditions aids the development of new materials with properties specifically tailored to withstand environmental-mechanical extremes.

xSol High Temperature Stage

Bruker’s xSol® High Temperature Stage enables quantitative, high-resolution nanomechanical and nanotribological measurements to be performed over a broad temperature range; up to 800°C. The xSol’s thermally stable stage design with dual feedback-controlled resistive heating elements eliminate thermal gradients within the sample and provide fast stabilization times. A heated microenvironment incorporated within the stage guarantees isothermal tip/sample contact and customizable gaseous environments reduce the effects of reactive chemistries, such as oxidation.

xSol Cryo

The xSol Cryo environmental stage extends quantitative nanomechanical and nanotribological characterization capabilities down to -120°C and beyond. Cooled nitrogen gas flows into the xSol stage and is heated to the user-defined temperature under tight PID control for fast stabilization times and low thermal drift. An integrated micro-chamber maintains a positive pressure of cooled dry nitrogen to minimize moisture condensation and sample icing, enabling reliable long duration testing near cryogenic temperatures.

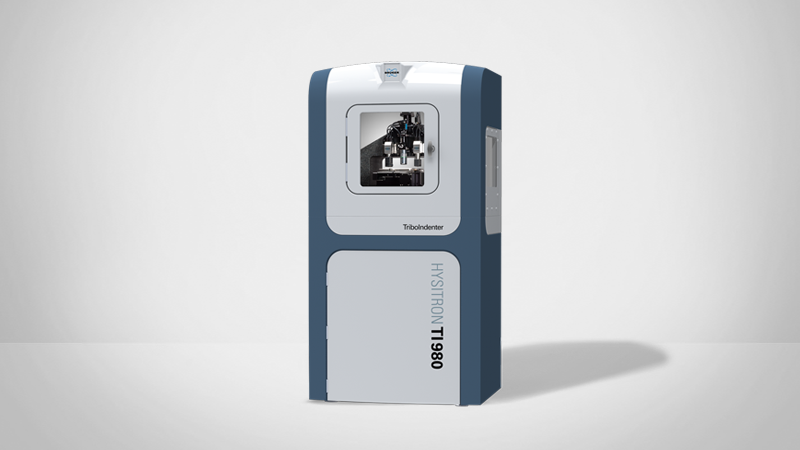

TI 980 IO - Glovebox Environmental Control

The TI 980 IO incorporates a custom-designed glovebox system to provide precise control over atmospheric conditions. The TI 980 IO achieves a working oxygen and water content of less than 0.1 ppm, ideal for reliably characterizing reactive surfaces. The TI 980 glovebox system achieves the same partial pressure of oxygen as a vacuum system operating at 10-4 Torr, without the complexity of operating in vacuum and with the benefits of testing in an environment that more adequately reflects the material’s working conditions.

xSol Humidity

Bruker’s xSol Humidity environmental stage enables characterization of hygroscopic effects on nanomechanical and nanotribological properties over a broad temperature and humidity range. In traditional mechanical testing, hygroscopic behavior can only be reliably analyzed when the water content reaches an equilibrium throughout the test specimen. Nanoscale testing enables accelerated testing of moisture effects since water only needs to permeate <100 nm for a hygroscopic effect to be observed.