High-Temperature Dynamic Mechanical Properties Characterization of Polymer Coatings via Nanoindentation

Key Points

- Demonstrated the use of a dynamic nanoindentation technique with a sharp indenter tip for characterizing the dynamic mechanical properties of polymer coatings at temperatures up to 280 °C; and

- Validated this methodology via excellent agreement to bulk DMA measurements.

Receive future Journal Club updates via email

J. Eng. Mater. Technol., Apr 2022, 144(2): 021011

DOI: 10.1115/1.4053029

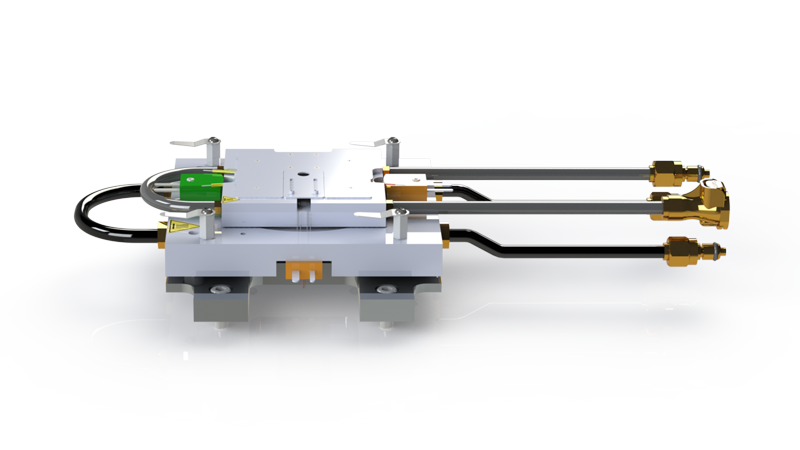

In this paper, our friends at DuPont independently investigated and verified performance of methodology, using a Berkovich indenter, nanoDMA III, and the xSol stage, to look at time- and temperature-dependent behavior of polymer films, including a reference polyester film. The test methodology is validated with bulk measurements on the polyester sample using uniaxial tension dynamic mechanical analysis. Of course, the Berkovich geometry isn’t the only probe that can be used for frequency and temperature sweeps, but this combination is well suited for polymer thin film work. For thicker polymer films, greater than 1 µm, we can look at blunter probes, but we do not suggest the use of frustum or flat punch probes on most polymers due to the many contact mechanics issues that are present. Those geometries are only well suited for the examination of ultra-soft materials, like hydrogels.

The industry-leading xSol performance allowed polymer transitions from solidus to rubbery plateau to be easily investigated.

One unique insight in this paper was the authors' use of the elasticity index in polymers. Though named differently, this ratio of hardness to modulus is used similarly to the plasticity index that is regularly used in ceramic research. Briscoe (1997) has a great explanation of how this is used in ceramics. Here it is used to describe the tribological performance of the films, as well as to give insight into the molecular structure of the polymers.

If you aren’t familiar, our webinars on the nanoDMA III technique are an excellent resource on the fundamentals (click on the links in the “Related resources” section below to watch).

KEY TERMS:

- Polymer film, Berkovich tip geometry, Elasticity index, Dynamic mechanical properties, Nanoindentation technique