Probing defect relaxation in ultra-fine grained Ta using micromechanical spectroscopy

Acta Materialia 2020, 185, pp. 309-319

One of the most exciting aspects of in situ nanomechanical testing is getting detailed mechanical information on a single defect or small group of defects, such as dislocations, cracks, or grain boundaries. Since the total volume of the test specimens is small, these can make up a sizeable fraction of the specimen and allow their behavior to be detected. The behavior of these defects forms the basis of our understanding of bulk mechanical behavior and helps materials scientists predict performance and understand failure. This article highlights novel techniques to study grain boundaries through use of dynamic mechanical testing to study their damping characteristics and the correlation to hardness and yield strength.

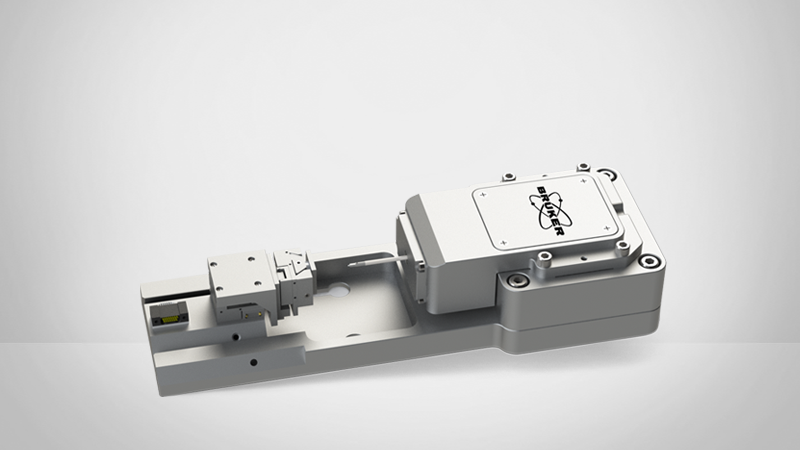

In this study, ultra-fine grained tantalum samples produced by high-pressure torsion were tested in situ SEM using the Hysitron PI85 PicoIndenter. During annealing at 400°C, these specimens showed unusual hardening behavior, which was hypothesized to be due to a change in grain boundary structure and dislocation sources. To explore this hypothesis further, micro-cantilevers were fabricated with focused ion beam machining and tested under dynamic loading with frequency sweeps. These allowed for the resonance peak to be mapped out, from which the damping characteristics of cantilevers with different heat treatments (as-deformed and heat-treated). An increase in damping was well-correlated to the increased hardness from the heat treatment, suggesting that grain boundary relaxation is the cause of the hardness increase.