Tribocorrosion

A Tool for Studying the Tribocorrosion Mechanism

Multiple Factors Contribute to Materials Degradation

The tribocorrosion process involves mechanical and electrochemical interaction between bodies in relative motion. The mechanical components in the tribocorrosion process are usually sliding wear, abrasion, cavitation damage, fretting, tribo-oxidation, and solid particle erosion. It is important to understand the mechanism of tribocorrosion for research and development of novel materials for service applications that involve simultaneous action of mechanical and electrochemical agents on engineering components. Such studies can provide tremendous benefits to automotive, biomedical, chemical, food processing, geothermal, marine, mining, and petrochemical industries, in terms reducing loss of materials and improving product performance and reliability.

Application Example: Tribocorrosion of Copper

Test Method

Recently, copper was studied as a model material for tribocorrosion experimentation in sodium chloride solution. The tribocorrosion test was performed using an alumina ball as a counter specimen.

The electrochemical polarization tests were performed with a standard Ag/AgCl reference electrode and a Pt-counter-electrode. Electrochemical measurements were done during tribocorrosion test, with and without a condition of sliding wear. The electrochemical polarization test data were used to obtain the chemical contribution (KC) towards the degradation of the copper. The contribution of the mechanical component (KM) toward the degradation of the copper during the tribocorrosion process was obtained by a direct measurement of the wear scar after the test, with and without cathodic protection.

A parameter (ξ) was obtained by taking the ratio of KC over KM. The degradation mechanism during the tribocorrosion process was defined by the value of ξ. The value suggests which process predominates over the other in a particular tribocorrosion process.

When the value of ξ is less than 0.1, the wear is the most contributing factor for the materials degradation. At the other extreme, where the value of ξ is greater than 10, the predominating process for materials degradation is corrosion. For the intermediate values between the two extremes, both wear and corrosion significantly contribute towards material loss, however, one has a little higher effect than the other.

Results

The value of ξ for tribocorrosion of copper in chloride media was 0.18. According to the line diagram, copper degrades by the mechanism of wear-corrosion, with mechanical wear providing a little more contribution than the corrosion. Wear-corrosion is the primary mechanism for the degradation of copper in siding wear conditions in chloride media. Bruker’s tribocorrosion test system is an outstanding tool for elucidating the various mechanisms that contribute to materials degradation during the tribocorrosion process.

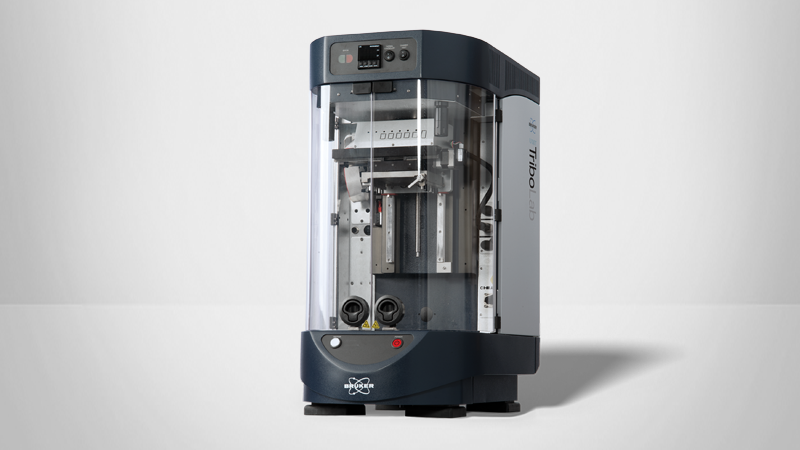

Tribocorrosion Test System

Bruker’s Tribocorrosion test system is built on the UMT TriboLab platform, and it offers precision control of load, speed, and position. The modular design of the UMT ensures flexibility and simplicity on a single hardware and software platform. It measures friction force and normal force to obtain the coefficient of friction (COF) as a function of time. The tribocorrosion cell is equipped with a three-electrode, electrochemical measurement system that provides the removal rate of materials. The test system also is capable of performing tests at elevated temperatures.