SiC Defectivity

XRDI

X-ray diffraction imaging (XRDI, also known as X-ray topography) is used to image crystalline defects in otherwise perfect (or near perfect) substrates.

The fully automated nature of the XRDI tools allows the densities for each defect type can be extracted and automatically reported via SECS/GEM for instantaneous feedback to production.

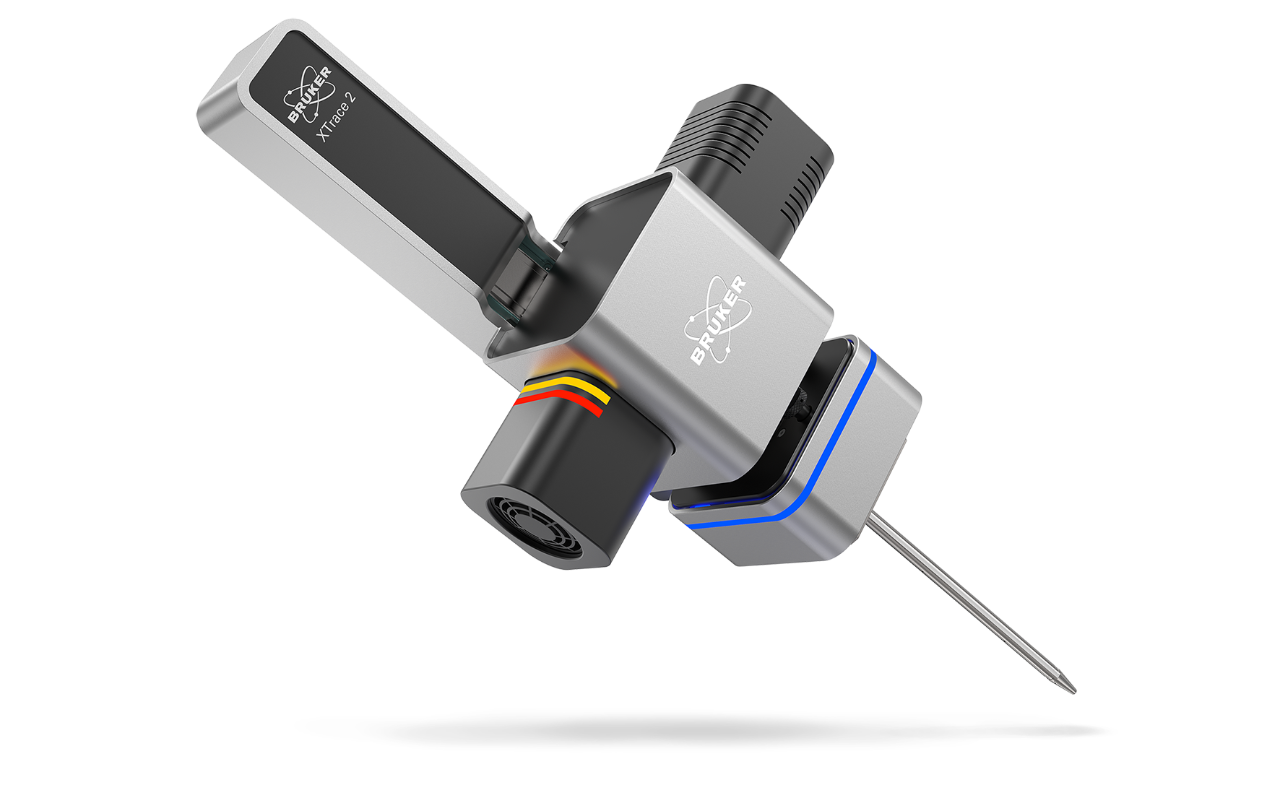

Micro-XRF

For large grains and single crystals, micro-XRF technique allows a quick mapping of crystalites by visualizing the appearance and disappearance of Bragg peak in the according spectral ranges. Such Laue map reveals the different crystallites domains. In sufficiently large single crystals, certain types of defects and orientation changes can be visualized.