HyperFluxTM

High Sensitivity Raman for Research, Development, and Optimization

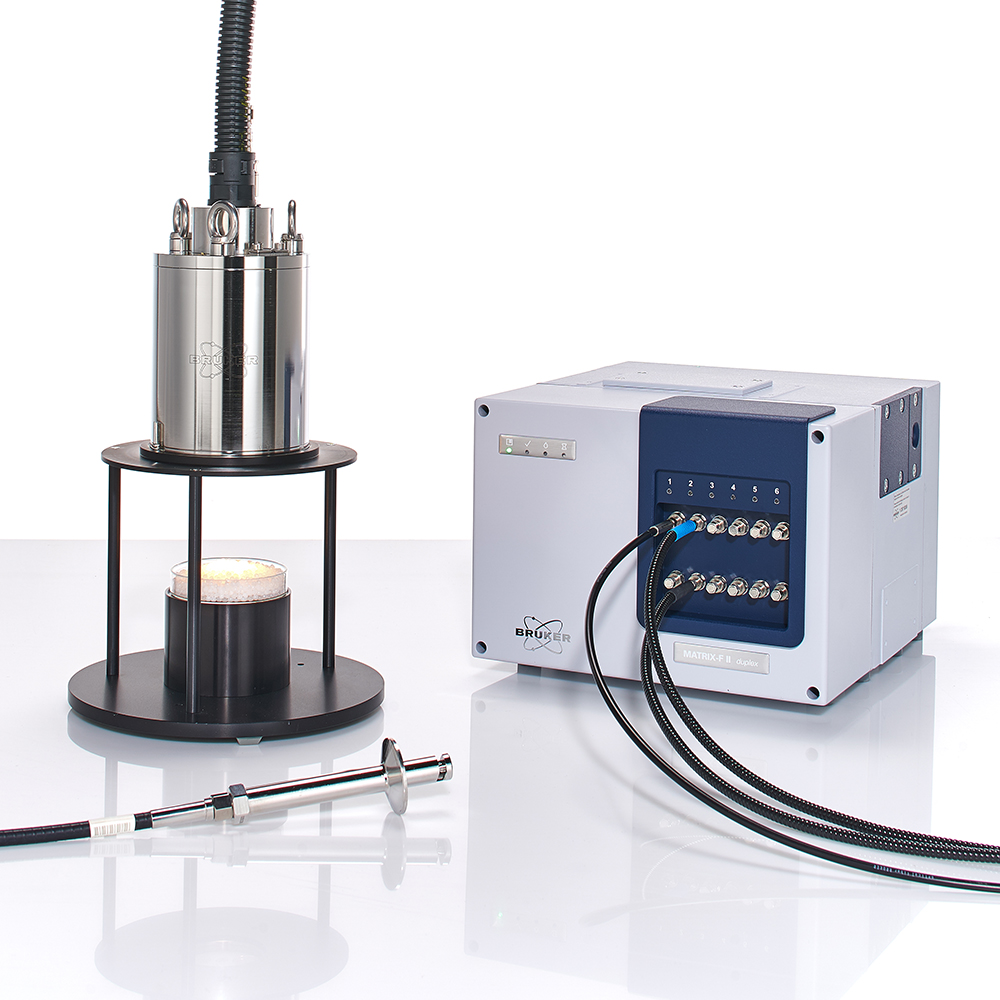

The HyperFlux™ is a high-performance Raman spectroscopy system designed for both laboratory and process development environments. Leveraging our patented High Throughput Virtual Slit (HTVS™) technology, the HyperFlux™ offers industry-leading sensitivity, faster measurement speeds, and lower limits of detection—empowering better decision-making with real-time, non-destructive analysis.

The HTVS™ design of the HyperFlux™ provides up to 30x higher signal intensity compared to conventional Raman spectrometers, without sacrificing spectral resolution. The result: more precise chemometric models, lower laser power requirements, and improved system safety—all in a rugged, compact form factor.

Key Features

- HTVS™ technology for industry-leading sensitivity and speed

- Stabilized 785 nm laser with multiple safety interlocks

- Real-time system health monitoring and dynamic recalibration

- Compact, lightweight design for flexible deployment

- Compatible with a broad range of Raman probes and sampling accessories

- Seamless integration with OPC UA and Modbus TCP/IP

- 21 CFR Part 11 compliance with IQ/OQ support for regulated environments

- Available ATEX-certified configurations for hazardous zones

The HTVS™ Advantage

Our patented High Throughput Virtual Slit (HTVS™) technology is the core innovation behind the HyperFlux™'s superior analytical performance. By eliminating the optical slit of conventional spectrometers, HTVS™ dramatically increases photon throughput without compromising resolution. This results in up to 30x higher signal intensity, faster acquisition times, enhanced signal-to-noise ratios, and lower detection limits, even for low-concentration analytes or samples with strong background fluorescence.

Built for Hazardous Environments

The HyperFlux™ is available in configurations suitable for hazardous (Ex) zones, enabling safe and compliant operation in chemically or physically demanding industrial settings. When paired with the OPIS 35™ ATEX/IECEx certified laser accessory, the system supports intrinsically safe Raman measurements, expanding its usability in petrochemical, pharmaceutical, and other regulated sectors.

Streamlined, Flexible, and Easy to Use

The HyperFlux™ is designed for intuitive operation and deployment in a wide variety of laboratory and pilot plant settings. Its compact, lightweight footprint makes it easy to move and integrate, while compatibility with a broad range of fiber-coupled Raman probes allows for flexible sampling configurations. Real-time system diagnostics, temperature monitoring, and dynamic recalibration features ensure reliable, consistent performance—even during long-term or unattended measurements. Controlled via the user-friendly SpectralSoft interface, the HyperFlux™ brings high-performance Raman within reach of users across disciplines.

Applications

Large Molecules (Biologics)

Raman spectroscopy is an ideal technique for upstream and downstream bioprocess development. The HyperFlux™ enables real-time monitoring of critical quality attributes like glucose and lactate in cell cultures, as well as capture and polishing phases in downstream workflows—all with plug-and-play method integration.

Chemicals

The HyperFlux™ provides precise molecular insights to support reaction development and optimization. Its high sensitivity enables kinetic studies, impurity profiling, and real-time tracking of critical species, even at low concentrations.

Food and Beverage

The HyperFlux™ enables rapid, non-destructive testing of oils, sugars, alcohol content, and structural components of foods. Raman spectroscopy helps laboratories develop and validate robust quality control methods with high specificity and minimal sample preparation.

Small Molecules (Chemical Drugs)

From early formulation to scale-up, the HyperFlux™ delivers rapid, high-resolution Raman data to support crystallization studies, blending and mixing validation, and advanced formulation development—making it a powerful tool throughout the development pipeline.

Oil and Gas

In oil and gas R&D environments, the HyperFlux™ offers fast, accurate Raman analysis of both direct properties like olefin or aromatic content and indirect parameters such as octane number or vapor pressure. It’s equally effective for gas-phase monitoring in pilot operations.

Polymers

Raman spectroscopy supports every stage of polymer research, from polymerization monitoring to additive detection and formulation optimization. The HyperFlux™ enables detailed tracking of physical and chemical properties during development and processing.