PAT for Batch Processing

PAT for Batch Processing

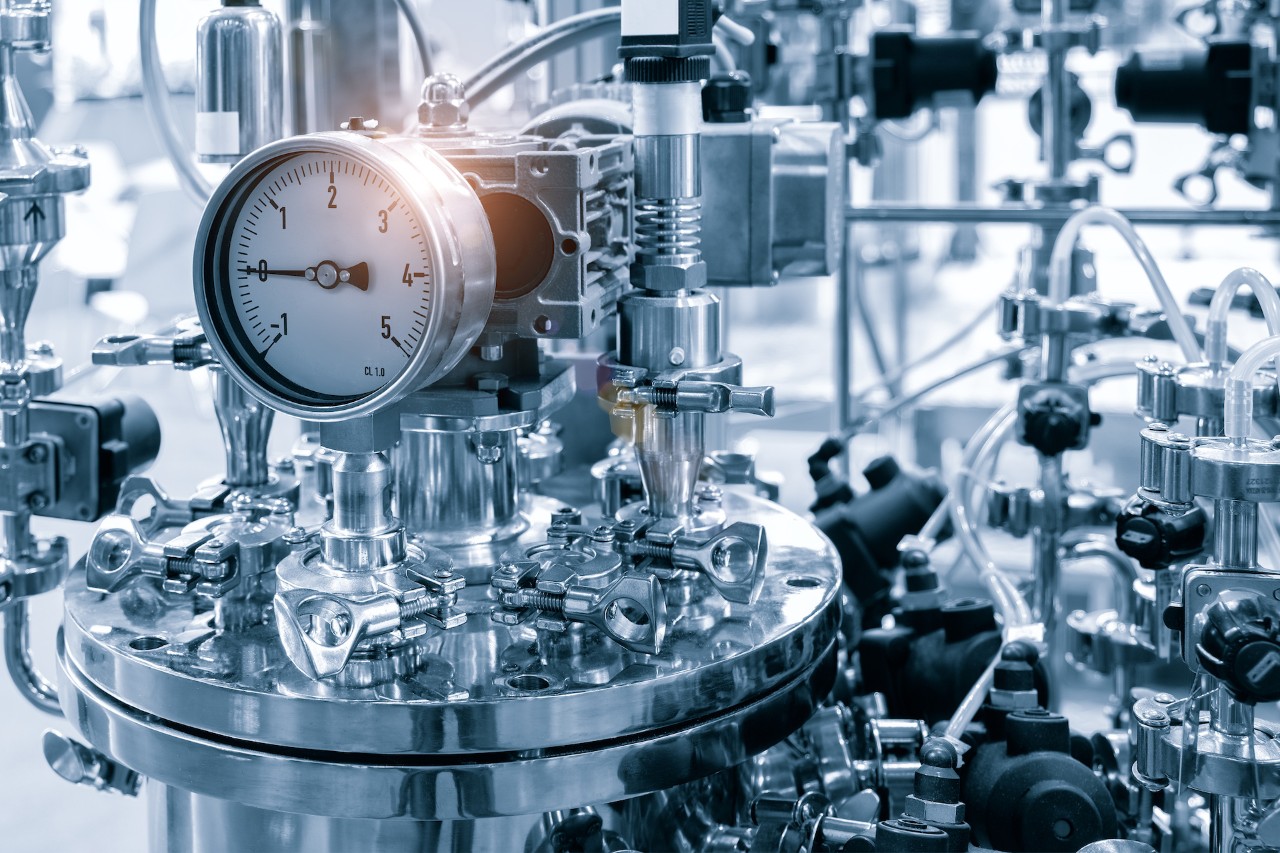

Process Analytical Technology (PAT) has been implemented into many batch manufacturing processes. Batch processing remains the most commonly used technique in many industries and globally there is a huge installed base of equipment.

When embarking on a PAT journey, the advice of starting with a small, simple deployment or ‘island of PAT’ with the aim of later expanding to other unit operations, is easier to follow in a batch process. For more details on this approach, visit PAT for Small Molecule.

As an example of the potential reduction of processing or cycle time that can be achieved, one small molecule batch manufacturing process has reduced production times from ~30 days to ~30 hours, simply due to the process improvements and the reduction or elimination of these IPCs. With PAT, the IPCs still take place, even more can be useful, but this happens automatically during the process.

Aside from enabling the transition towards continuous manufacturing, PAT can reinvigorate existing batch facilities and dramatically increase the quantity and quality of products made with the existing, installed infrastructure.

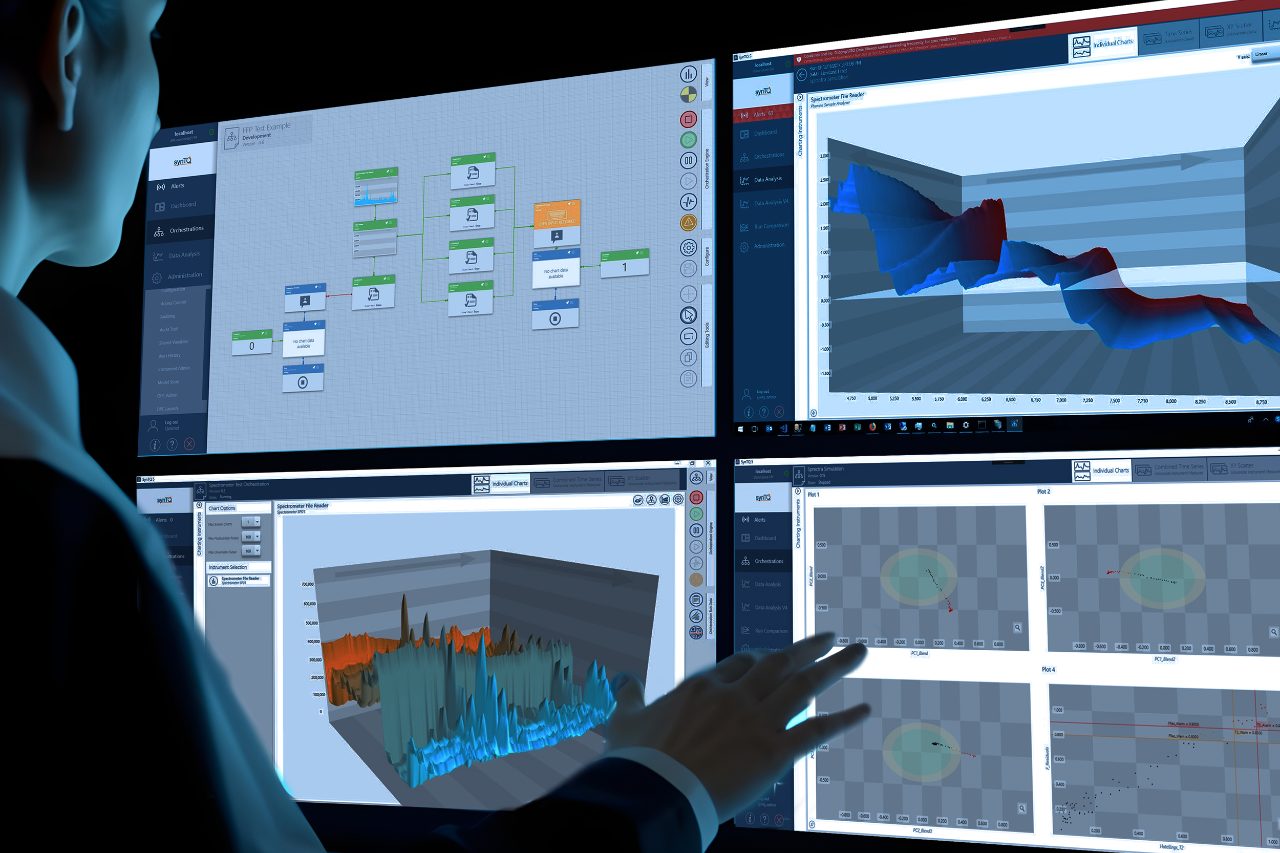

Bruker offers a wide range of instrumentation-based PAT solutions and recommends synTQ , the instrument agnostic software package from Optimal Industrial Technologies.

Benefits

Many benefits can be realized with PAT:

- Improve manufacturing efficiency, quality and the consistency of quality

- Increase acceptable raw material variation

- Reduce waste

- Significantly shorten processing time, due to processing improvements and the potential elimination of manual in-process checks (IPC)