Bauxite Mining and Aluminum Processing

Bruker's Analytical Technology Helps to Meet Production Targets, Ensures Quality and Saves Costs in the Aluminum Industries

Bauxite ore is the leading source for aluminum. Bauxite is a hydrated aluminum oxide in the form of gibbsite, boehmite or diaspore that forms through surface weathering and direct chemical precipitation. Surface processes introduce a complexity and diversity of ore and impurity compositions that requires careful consideration of analytical technology when designing exploration, grade control, and process control workflows. Bruker’s analytical tools empower all phases of bauxite mining from exploration to remediation.

XRF for all Phases of the Bauxite to Aluminum Value Chain

X-ray Fluorescence (XRF) XRF provides chemical analysis. Uses of XRF during bauxite mining and exploration include:

Exploration mapping, core scanning, and identification of prospective deposits

Delineation of the extent of resource and cutoff grade during mine assessment

Grade control during mining in both central laboratories and on-site

Process control for alumina processing and electrolysis, including analysis of additives to electrolysis systems such as cryolite, CaF2, AlF3, MgF2 or LiF

For metals characterization and final product QA/QC of cast aluminum and its alloys, refractory materials, raw material for anode production, and the anode coals

Explore XRF Options

| S1 TITAN 800 | Portable XRF | Portability and power define the S1 TITAN, with a rugged case, Titan Detector Shield™ and GeoExploration calibration. Portable XRF is ideal for on-site analysis, exploration, and core scanning. |

| CTX | Countertop XRF | The CTX is a rugged and portable single-sample countertop XRF with battery backup, safety interlocked lid, Titan Detector Shield™ and push-button operation that is ideal for quick-look grade control and process control. |

| S2 PUMA | Benchtop ED-XRF | The S2 PUMA Series 2 is the standard for laboratory ED-XRF analysis, equipped with the intuitive TouchControl™ interface and XY robotic multi-sample or carousel sample changer. |

| S6 JAGUAR | Benchtop Sequential WD-XRF | The S6 JAGUAR provides WD-XRF performance in a compact package ideal for any laboratory analysis. |

| S8 TIGER | Sequential WD-XRF | The S8 TIGER Series 2 sequential WDXRF provides outstanding superior analytical performance for the most demanding mineral and mining applications. |

Bulk Mineral Analysis

XRD directly measures the mineralogy. Knowing about mineral impurities such as clay or iron oxide in bauxite is the key to beneficiation in the alumina refinery and thus reduces residues. In the smelter XRD measures the mineralogy of the congealed electrolyte. Control parameters are derived that are essential for managing the operation of the smelter cells. Furthermore, the anode quality is monitored by XRD.

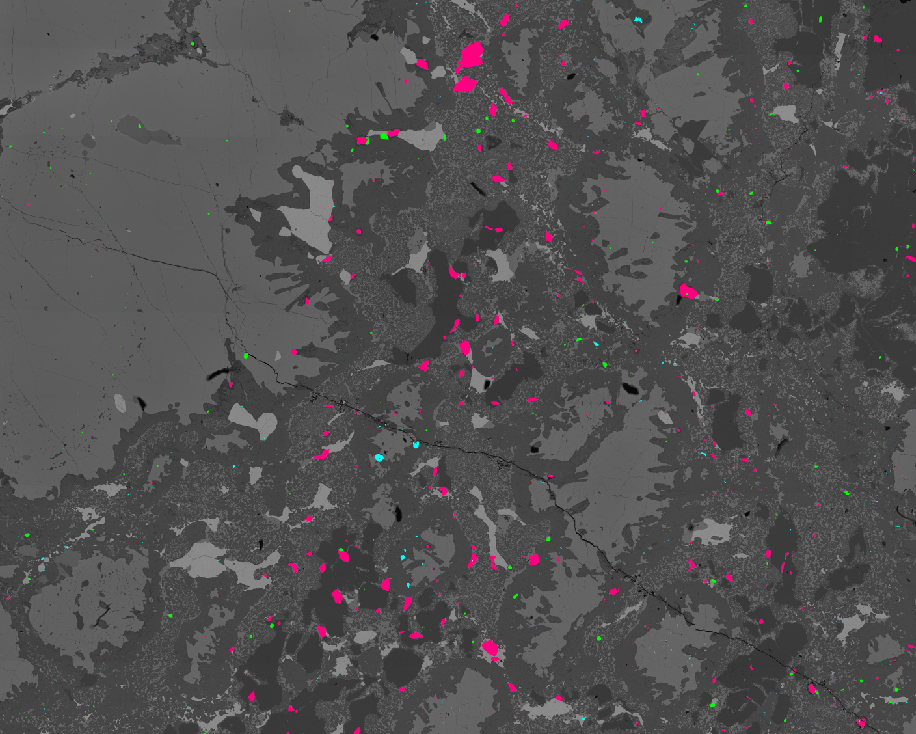

Microanalysis and Automated Mineralogy

Automated mineralogy combines the imaging power of scanning electron microscopy (SEM) with energy dispersive spectrometry (EDS) to generate mineral maps and quantified elemental data. Automated mineralogy and associated detectors enable the characterization of target minerals such as gibbsite, kaolinite, and iron oxi-hydroxides. Example applications include:

Exploration assessments providing identification of ore mineralogy and morphology as well as textural associations between ore minerals and gangue minerals

Risk assessment for processing planning including minerals associated with reactive silica and identification of problematic minerals

Optimization of comminution during the beneficiation process by quantifying mineral liberation in feeds and tails

Positive Materials Identification

Positive Material Identification (PMI) is a Non-destructive Testing (NDT) method critical in the mining industry. PMI is used to verify that supplied materials conform to the proper standards and specifications. The verification of alloy grade become a mission-critical safety consideration for mining, mineral processing, and smelting facilities that utilize high-temperature and high-pressure processes. Bruker’s NDT solutions include Optical Emission Spectroscopy (OES) and X-ray Fluorescence (XRF) for positive identification of nearly any alloy.

Environmental and Remediation

Bauxite mining exposes large areas to weathering and runoff, requiring special considerations for environmental management. Monitoring is important for the transport of heavy elements in surface water, the analysis of processing fluid discharge, and the assessment of contamination for closure and remediation. Bruker partners with operators to develop monitoring and remediation workflows that are efficient and accurate. Example applications include:

Utilizing Total Reflection XRF (TXRF) for hassle-free testing of heavy elements in water

Mapping contamination hot-spots with portable XRF

Monitoring acid generation possibilities with automated mineralogy

Publications Related to Bauxite

- 2018 - Sustainable Utilization of Metals - Processing, Recovery and Recycling: (Open Access) Scandium and Titanium Recovery from Bauxite Residue by Direct Leaching with a Brønsted Acidic Ionic Liquid

- 2017 - Journal of Hazardous Materials: Acid transformation of bauxite residue: Conversion of its alkaline characteristics

- 2012 - Broekmans M. (eds) Proceedings of the 10th International Congress for Applied Mineralogy (ICAM): Advances in Quantitative X-Ray Mineralogy: Mixed Crystals in Bauxite

- 2011 - Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy: Raman spectroscopic analysis of real samples: Brazilian bauxite mineralogy