Surface Finish Optimization for Advanced Manufacturing by Optical Profiler

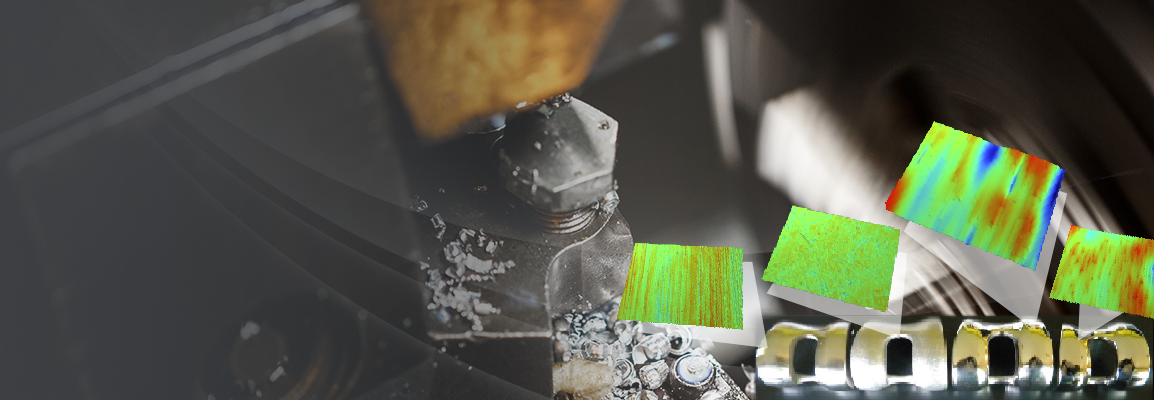

Controlling surface texture is critical to the function, lifespan, and aesthetics of product parts and components

This webinar focuses on how advanced optical profilers can be used to accurately assess and gauge ISO 25178 compliance of complex surface textures through the Sa areal roughness parameter

Webinar Summary

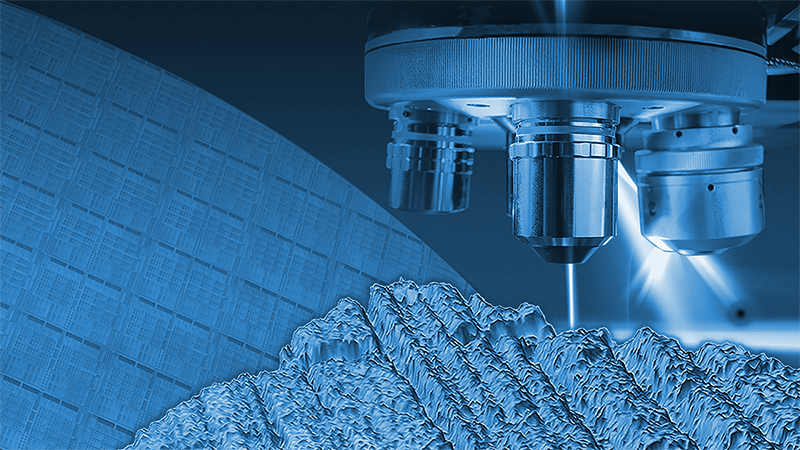

Today's manufacturing processes go beyond simple stamping, molding, or CNC machining. They often include advanced processes--like imprinting specific textures on surfaces, This now-common surface finishing process in manufacturing aims to improve the function of parts and components, extend their useful life, or enhance their aesthetics.

Geared towards viewers like quality control engineers, metrology engineers, material development researchers, application engineers for additive and 3D printing manufacturing, and designers of finishing means, this webinar explores:

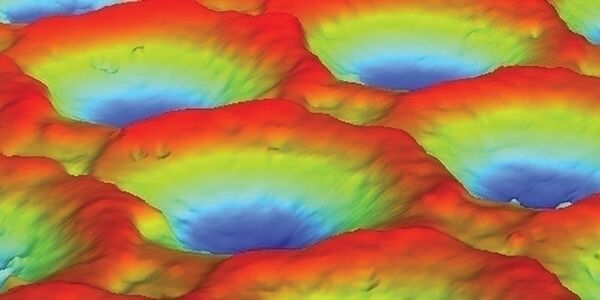

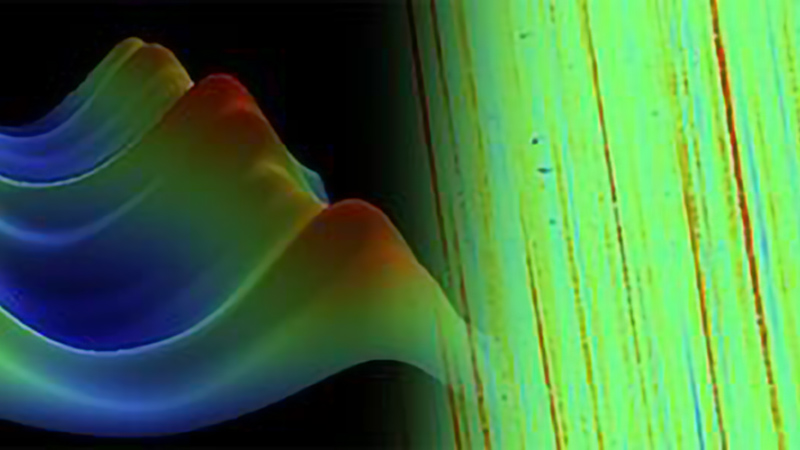

- The mechanisms behind our advanced optical profilers' ability to accurately assess complex surface texture through areal roughness parameters in compliance with ISO 25178;

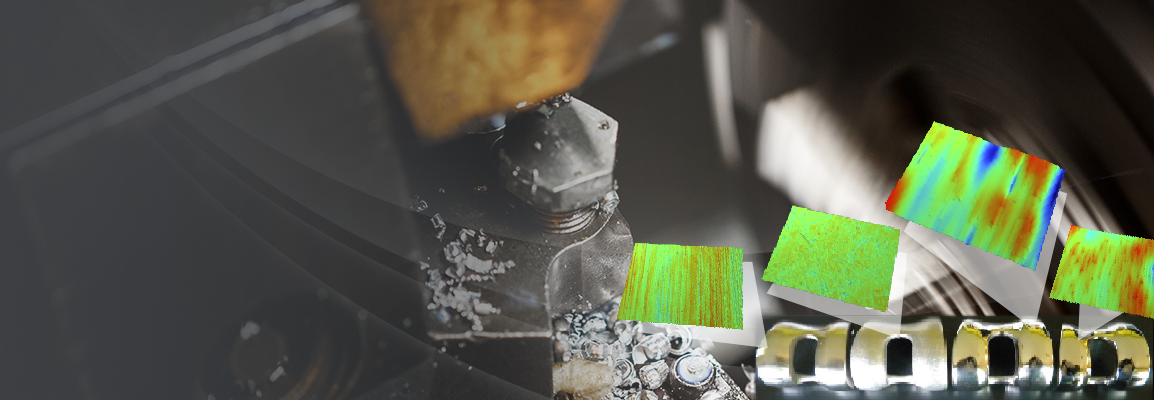

- How these same profilers can be used to optimize manufacturing processes and control the quality of the imprinting process; and

- Practical industrial cases, ranging from an mechanical part to a polymer 3D-printed surface made via additive manufacturing.

This webinar was presented on June 13, 2020.

Find out more about the technology featured in this webinar or our other solutions for surface finish measurement:

Presentation Overview

| Presentation Lenght | Title | Presenter | Abstract |

| 30 min | Finishing Process for 3D Printed Polymer Surfaces | Samuel Lesko, Ph.D. | This presentation explores the use of optical profiler techniques for post-processing and quality control in 3D-printed polymer manufacturing. In the included case study, Bruker optical profilers are used to assess and compare the areal parameters of a 3D-printed polymer part that has been subjected to different post-processing/finishing processes. Optical profilometry enables us to quantify and rank these finishing processes and select optimum processes to meet ISO 25178 standards. |

| 30 min | Surface Texture and Paint Adhesion | Donald K.Cohen, Ph.D. | This presentation discusses how texture measurements of functional surfaces are limited by exploration equipment and how the SMART methodology for texture functionality research guides researchers toward the correct answers. |

| 35 min | What Texture for What Functionality and Howto Characterize It? | Raphaël Delttombe, Ph.D. | This presentation covers the use of 3D optical profilometry, and multi-spectral analysis, to demonstrate correlation between the base substrate texture features to the final paint appearance. |

| 20 min | Live demo of the ContourGT-X | Samuel Lesko, Ph.D. | - |

Featured Products and Technology

Speakers

Raphaël Deltombe, Ph.D.

Morphomeca (LAMIH, Valenciennes, France)Raphaël Deltombe has a Ph.D. in mechanical science and hold CNRS's research engineer position at Morphomeca team lead by Prof. Maxence Bigerelle. His main research activities are centered on exploration and analysis of microscopic texture applied to industrial manufacturing pieces in order to identify specific roughness signature as a function of environment parameters (Process parameters, lifetime...)

Donald K. Cohen, Ph.D.

Michigan Metrology, LCC (USA)

Donald Cohen has Ph.D. in Physics and Optical Sciences from the University of Arizona. Since 1994, he has established servicing company Michigan Metrology, LLC to help engineers and scientist solve problems related to “leaks, squeaks, friction, wear, appearance, adhesion and other issues”, using 3D Surface MicroTexture Measurement and Analysis. Prior that, he held position at IBM before joining Wyko corporation to develop 3D surface texture metrology instrumentation.

Samuel Lesko, Ph.D.

Dir. of Technology and Apps Development for Tribology, Stylus & Optical Profilers, Bruker

Samuel Lesko has over 20 years of optical and stylus profiler applications experience, particularly in using white-light interferometry in a wide variety of fields, from MEMS and semiconductor to automotive and aerospace. He is a member of SME and part of ISO/TC 213/WG committee (areal roughness) and obtained his physics Ph.D. and material science engineering degree at the University of Burgundy in France.