Electro-Mechanical Tribology and the Influence of Roughness and Lubrication

Current across a contact can generate heat, change properties, and damage surfaces

In this webinar, guest speaker Prof. Jackson presents his work on numerical models of mixed-lubrication cases that incorporate coupled electromagnetic, solid, and fluid mechanics solutions as well as effects from roughness. This comprehensive approach can result in models that are powerful analytical and predictive tools for applications where contacts can be electrified, such as electric vehicles, power generation, and spacecraft.

Watch this on-demand webinar to learn:

- The relevance of effective friction, wear, and lubrication (tribology) practices, and how surface roughness can be an important factor

- What changes and new considerations arise when an electrical current is introduced across the contacts

- How numerical models can be built to address the factors of added electrical current and multi-length-scale surface roughness

Guest Speaker Abstract

The transportation, power generation, manufacturing, and biomedical industries all depend upon effective friction, wear and lubrication (tribology) practices for efficient and reliable performance. In lubricated contacts, the mechanisms of wear and friction are governed by both solid and fluid interactions. At small lubricant film thicknesses, the surface roughness affects both the lubricant flow and solid contact. In addition, in electric vehicle, power generation and space applications, the contacts can be electrified. Electrical current across a contact can heat the material, change its properties, and in some cases arcing can damage the surfaces. Therefore, numerical models of mixed-lubrication cases must incorporate coupled electromagnetic, solid and fluid mechanics solutions. These models must also include the effect of micro- and sometimes nano-scale roughness. Then the considered geometry spans several difference scales. However, if researchers can overcome these obstacles the resulting numerical models prove their worth as powerful analytical and predictive tools.

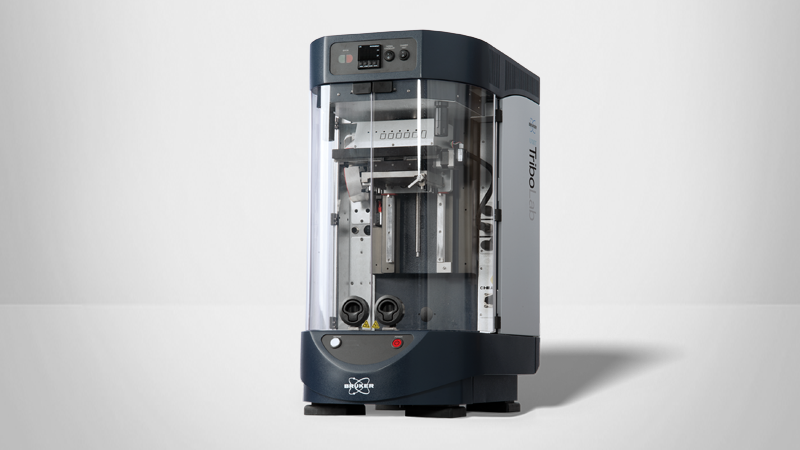

Find out more about the technology featured in this webinar or our other solutions for electro-mechanical tribology:

Related Resources:

Featured Products and Technology

Guest Speaker

Robert L. Jackson, Ph.D., Professor of Mechanical Engineering, Auburn University

Robert L. Jackson is a Professor of Mechanical Engineering at Auburn University. In 2024 Prof. Jackson was named Editor-in-Chief of the ASME Journal of Tribology. Prof. Jackson’s research interests include contact mechanics, hydrodynamic lubrication, lubricant additives, electrical contacts, and machine component design. In 2012, Prof. Jackson also initiated one of the first undergraduate minors in the field of Tribology. He is an ASME and STLE Fellow.