Application Note: Chemical Characterization of Polymeric Films, Blends, and Self-Assembled Monomers

Transforming polymer research with AFM-IR

Infrared (IR) spectroscopy is one of the most recognized analytical measurement techniques in academic, government, and industrial R&D laboratories for the characterization of polymeric materials. The spatial resolution of conventional bulk IR spectroscopy is limited by Abbe diffraction laws to between 3–10 µm, depending on the method used. Atomic force microscopy (AFM) is a widely used nanoscale imaging technique that provides the user with a high spatial resolution topographic map of a sample surface. Until now, the major drawback of AFM has been its inability to chemically characterize the material underneath the tip. When combined with an IR source, the resulting AFM-IR technique breaks the diffraction limit of conventional IR spectroscopy by orders of magnitude, while still providing the high-resolution imaging capabilities of AFM.1 This application note discusses the use of AFM-IR to address nanoscale chemical characterization on a range of polymeric and thin film samples.

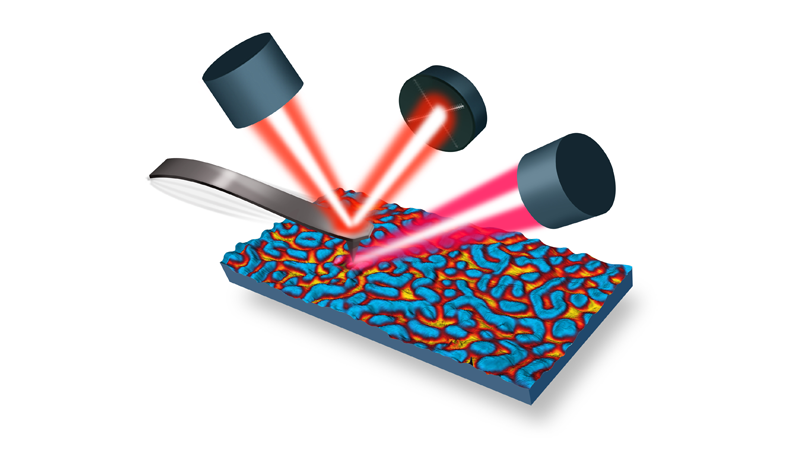

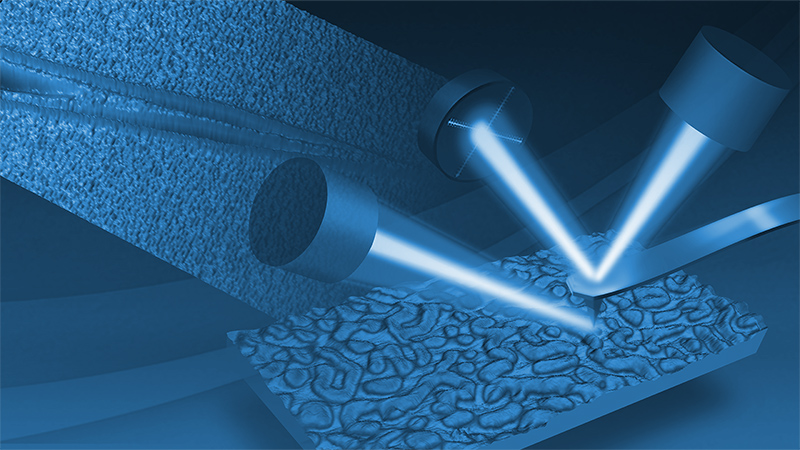

Resonance-enhanced AFM-IR

The recent coupling of AFM with pulsed tunable IR laser sources has enabled the collection of IR spectra at spatial resolutions below 100 nm × 100 nm.2,3 The sharp AFM tip acts as a local detector of IR absorbance at the surface of a sample it contacts. When the wavenumber of the laser source is in resonance with a molecular vibrational frequency, the IR radiation can be absorbed and the sample expands when the molecules return to their ground vibrational state after exchanging energy with the sample matrix. This causes the sample to thermally expand over an area corresponding to the focused IR laser spot. The AFM cantilever will deflect because of the local thermal expansion of the material in proximity to the apex of the AFM probe, providing significantly higher spatial resolution that is not limited by the diffraction limit of the IR wavelength. In the initial configuration of this technique, the optical parametric oscillator (OPO) tunable laser source had a repetition rate of 1 kHz and a pulse length of ~10 ns, which would cause a rapid expansion of the sample inducing an impulse in the cantilever. This would cause the cantilever oscillation to ring down at its natural resonance frequencies after each laser pulse. We describe here how replacing the OPO tunable laser source with a variable repetition rate quantum cascade laser (QCL) produces a two orders of magnitude signal enhancement of the AFM-IR signal. This enhancement is accomplished by tuning the QCL repetition rate to match the contact resonant frequency mode of the AFM cantilever.2,3 At the contact resonance, the oscillation amplitude of the cantilever is significantly increased relative to off-resonance frequencies. An additional enhancement of the AFM-IR signal results when a gold-coated AFM tip is used, producing a “lightning rod” effect that enhances or localizes the electric field at the tip apex. The combination of matching the repetition rate of the laser to the contact resonance of the AFM cantilever and using a gold-coated probe allows for the collection of IR spectra of samples on arbitrary substrates down to thicknesses of ~10 nm. If the thin film sample is deposited onto a gold substrate, a further increase in the local enhancement of the electric field allows measurements down to 1 nm. This enables the AFM-IR technique to detect monolayer coverages of material on metal surfaces at lateral spatial resolutions down to 25 × 25 nm.

Characterization of multilayer films

Multilayer films are of great importance in many products, especially packaging materials. As multilayer films become thinner and the number of individual layers increases, there is a need to characterize these structures.4 FTIR spectroscopy is widely used for characterizing cross sections of multilayer films, providing information about the chemical nature of the individual polymers layers, as long as they are at least a few micrometers thick. Previously, to analyze individual layers that are smaller than the diffraction limit of conventional FTIR, films had to be delaminated. AFM-IR is able to overcome these obstacles, and thus can provide true nanoscale chemical characterization.

To reverse engineer multilayer films, samples are cross sectioned by microtome and are placed on an IR transparent substrate (ZnS) for analysis, shown in Figure 1a. Subsequent AFM-IR spectra are denoted by the respectively colored markers. In this case, the contents of the film were successfully identified as polyethylene and polyamide (see Figure 1b and 1c).

Each layer within multilayer films can have a specific function, such as oxygen or moisture barrier layers. It is very common for these materials to be incompatible with one another and, as a result, “tie” layers are needed to bind these layers together during film formation. Until now, it has been impossible to characterize these tie layers by FTIR spectroscopy due to their thickness (<500 nm).

Such an example is the relationship between polyethylene (PE) and polyamide (PA). These polymers are not compatible within films, and a tie layer is generally required. Figure 2 shows an AFM height image and AFM-IR spectra from the boundary region between the PE and PA layer of a cling film cross section. The nine colored marker locations on the AFM image correspond with the AFM-IR spectra of the same color (100 nm spacing).

Tapping AFM-IR of a PEMA/PMMA

Polymer blend systems often reveal evidence of phase separation at spatial scales. These submicron domains are often apparent in AFM images of the sample topography and phase. AFM alone, however, is not able to definitively determine the chemical composition of the domains observed. Figure 3 shows tapping AFM-IR spectra and an image that clearly demonstrates the phase separation between the poly(ethyl methacrylate) (PEMA) matrix and poly (methyl methacrylate) (PMMA) domains based on the characteristic IR absorption band of PEMA at 1026 cm-1 (ambient condition).

Measuring monolayers

Self-assembled monolayers (SAMs) of 4-nitrothiophenol (NTP) and a monolayer island sample of poly(ethylene glycol) methyl ether thiol (PEG) were deposited on templatestripped gold substrates. AFM topography measurements were used to verify that the NTP monolayer film thickness was less than 1 nm, as shown in Figure 4a. AFM-IR spectra and molecular structures of NTP SAMs on gold (in blue) are shown in Figure 4. Each AFM-IR spectrum originates from an approximate sample surface area of 25 × 25 nm, limited only by the contact area of the AFM probe with the sample.3 Corresponding IR reflection absorption spectra recorded over a substantially larger area of NTP SAMs are shown in red for comparison (see Figure 4c). A strong NTP absorption peak around 1339 cm-1 correlates to the symmetric NO2- stretching mode, while the weaker absorption band around 1175 cm-1 is associated with an aromatic CH-bending mode. An array of AFM-IR spectra were collected across a gap in the monolayer (see Figure 3c). The spatial resolution achieved for these measurements was ~20 nm.

Figure 5 shows the AFM topography image (top left) and an IR absorption image with the IR laser tuned to the fixed wavenumber of 1340 cm-1 (top right) of a monolayer island film of PEG on gold. The AFM image indicates the PEG islands are about 4 nm thick. The IR absorption band at 1340 cm-1 is assigned to a CH2-wagging mode and the image confirms the location of the PEG island regions. PEG monolayer island regions as small as 25 × 25 nm are easily resolved in the IR absorption image. The broad IR band centered at 1102 cm-1 is assigned to the C-O-C antisymmetric stretching mode. Typically, one would expect to see a strong CH2-scissoring band at 1460 cm-1, but it is not apparent in this AFM-IR spectrum. The fact that it is missing suggests that the ethoxylate chains extend vertically from the gold surface. Since the incident is polarized normal to the surface in this experiment, only vibrations with electric dipole-transition moments oriented parallel to this direction will absorb the incident IR radiation. The CH2-wagging and C-O-C antisymmetric stretching modes, on the other hand, both have electric dipoletransition moments oriented along the surface normal, which is why their IR absorbances are so strong.

Quantifying chemical content in nanoscale polymer domains

Polypropylene (PP) is one of the most important and widely used polymers due to its heat resistance, tensile strength, processability, and low cost. However, the applications for PP are often limited by its poor impact resistance, especially at low temperatures. In response, a new copolymerization process has been developed that allows for the blending of other polymers with PP to improve the overall performance, while increasing high-impact resistance.5

Figure 6, shows three distinct regions in a high-impact polypropylene (HIPP) material: the matrix, intermediate layer, and core. To fine tune the performance of HIPP, the ability to probe the chemical composition of each region is necessary.

In general, IR spectroscopy is a powerful tool for the evaluation of chemical composition, however, domains within HIPP are too small to be analyzed by conventional FTIR microspectroscopy. On the basis of the strong correlation between conventional FTIR and AFM-IR, FTIR was employed to generate a calibration from standards with known material composition to correlate the ethylene content in the copolymers with the peak area ratio of the CH2- and CH3- bending bands at ~1456 cm-1 and ~1378 cm-1, respectively.

Figure 7 shows a zoomed-in AFM image of the nanoscale domains within HIPP. Markers on the image correspond to the location where AFM-IR spectra were collected from the core (red), intermediate layer (blue), and matrix (black).

The collected spectra were normalized to 1378 cm-1 to allow for the comparison of the AFM-IR peak ratio data to the FTIR calibration curve (see Figure 7c). By comparing the peak ratios to the calibration curve created by the FTIR spectra, the chemical content of each region can be determined (see Table 1).

Conclusions

AFM-IR is a powerful tool for characterizing a variety of polymer materials. By combining the capabilities of AFM and IR spectroscopy, Bruker's Anasys nanoIR3 system can obtain topographical images of the sample surface and characterize the chemical composition of these materials with spatial resolution <20 nm. This application note has shown that AFM-IR can be used to characterize or reverse engineer polymer multilayer films, chemically identify individual components in a polymer blend, measure the molecular orientation in self-assembled monolayer island films, and quantify the chemical content of polymer crystallinity with high spatial resolution.

References

- Dazzi, A.; Prazeres, R.; Glotin, F.; and Ortega, J.M.; Opt. Lett. 30, 2388-90 (2005).

- Lu, F..; and Belkin, M.A.; Opt. Express 29, 19942-47 (2011).

- Lu, F.; Jin, M.; Belkin, M.A.; Nat. Photonics 8, 307-12 (2014).

- Kelchtermans, M; Lo, M; Dillon, E; Kjoller, K; Marcott, C; Vib. Spec. 82, 10-15 (2016).

- Tang, F.; Bao, P.; Su, Z., Analytical Chemistry 88 (9), 4926-30 (2016).

©2019 Bruker Corporation. Anasys is a trademark of Bruker Corporation. All other trademarks are the property of their respective companies. All rights reserved. AN202, Rev. A0.