Hot Hardness Testing

Measure Mechanical Properties at High Temperatures

In applications such as engines or gas turbines, improved efficiency can be achieved through operation at higher temperatures. Additionally, applications such as hot working of metals, catalytic processing to remove harmful greenhouse gases, steam turbines, and petrochemical processing all require materials that maintain their strength at high temperatures, in combination with corrosion-resistance and/or wear-resistance. Thus, it is useful to be able to compare materials under high-temperature service conditions.

Why Hot Hardness Testing?

The answer is simple: hardness testing is easy, fast and inexpensive. While tensile testing is the traditional method to assess material strength at high temperature, tensile tests require specialized samples and equipment. A hardness test, on the other hand, can provide strength-based comparisons of materials using very simple sample shapes, including flats or rods.

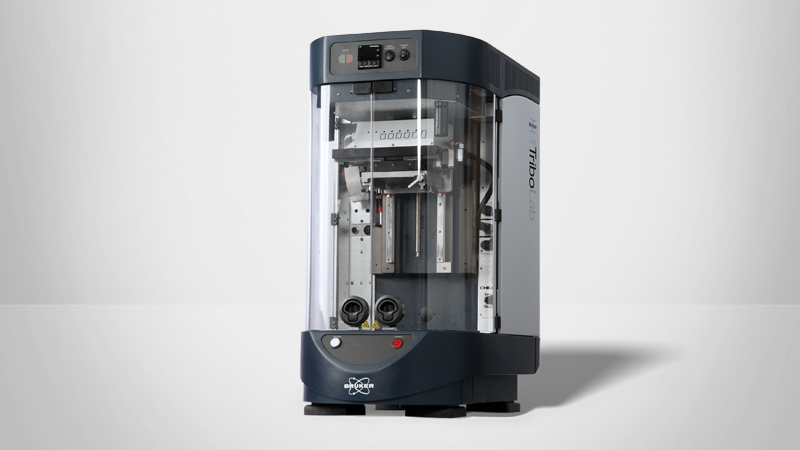

With various indenters available with a range of force sensors, the UMT TriboLab mechanical tester can perform a wide variety of material screening and comparison tests under conditions from room temperature up to 1000°C. Plus, the hardness testing can be performed on an extremely wide range of materials, from plastics to soft metals to super-alloys. High-temperature wear tests also can be conducted on the same samples.