Ceramics

Inevitable for all Industrial Processes at High Temperatures

For the protection of kilns, vessels, pipelines, and machinery the surfaces are lined with refractories specific for every kind of process.

All production accessories must withstand high temperatures; high product quality for high performance ceramics and refractories is required to ensure long-term durability.

The spatial distribution of certain elements, crystallography and phase boundaries yield information about the quality of the raw material and the finished ceramics. For successful quality check and failure analysis of cooled samples, Bruker's Micro-XRF tabletop instruments and electron microscope analyzers provide non-destructive solutions to perform spatially resolved analyses of texture and element distributions down to ppm levels.

The manufacturing of ceramics and refractories require a tight elemental analysis of the raw materials, the production processes and the final products. For this analysis, X-ray fluorescence (XRF) is the optimal technique as these chemical inherent materials are measured directly as solids without any digestion in hazardous acids. Typically, wavelength dispersive (WD) XRF is the method of choice, mainly due to the possibilities of measuring major and minor components as well as traces at lower concentration levels. WDXRF instruments used for this application are S6 JAGUAR and S8 TIGER.

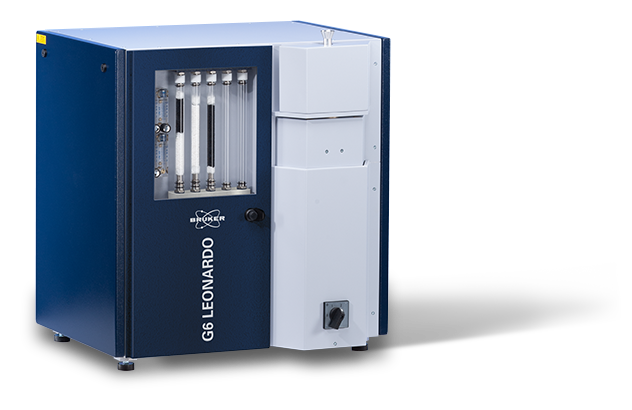

From refractory materials for the steel and cement industry to highest performance ceramics in electronics or in metal cutting, refractory oxides, nitrides, and carbides have a wide usage. The unique properties of ceramics and refractories are influenced in fundamental ways by the level of oxygen, nitrogen and hydrogen present in the process or in the final product. With SampleCareTM, FusionControl and its robustness, the ONH Analyzer G6 LEONARDO is an excellent tool for the fast analysis of raw materials, intermediates and final products.