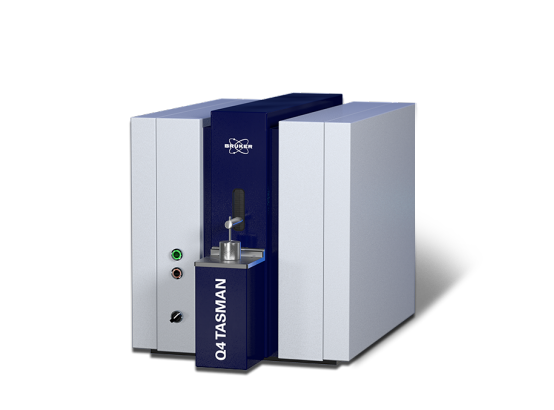

Q4 TASMAN Series 2

Process and quality under control

Ready-to-use metals lab

Outstanding analytical performance with low cost of ownership

Outstanding solution for metal analysis: Analytical performance, ease-of-use and cost-effective operation at optimal level

Q4 TASMAN Series 2 - All-Over Improvements

Our engineers took every opportunity to further improve the analytical performance in the new Q4 TASMAN Series 2. The analytical range of the Q4 TASMAN Series 2 has been extended for many elements, and new element sets enable the analysis of new alloy types. Addressing the entire metals market, dedicated Analytical Solution Packages (ASPs) are available for all ten common metal bases: Fe, Al, Cu, Ni, Co, Pb, Sn, Zn, Mg, and Ti.. These ASPs include full element sets, calibrations, alloy groups, and standardization samples. ASPs provide analytical performance that’s precisely tuned for the metals world - and its future demands.

Key Benefits

- MultiVision™- the innovative optics concept delivers the optimal solution for your applications, in the most economical way.

- SmartSpark™ - the further optimized Digital Spark Source delivers improved analytical precision and shorter time-to-result.

- Low Maintanance spark stand with improved co-axial argon flow and pneumatic sample clamp for hassle-free operation.

- ELEMENTAL.SUITE delivers highest functionality combined with ease-of-use for information @ your fingertips.

Why do I need spark-OES?

OES gives you an ultrafast analysis of your solid metal sample without complications. All relevant elements are simultaniously determined.

Q4 TASMAN Series 2 Specifications

| Spark Stand Sample Clamp | Low maintenance spark stand with co-axial argon flow Pneumatically driven, 120 mm height | Minimized maintenance and argon consumption, easy analysis of wires and small pieces but also accepting bulky samples Hassle-free sample handling and improved operiational safety |

| SmartSpark™ | Optimized digital spark source for stable spark generation up to 1,000 Hz | Improved precision and stability |

| MultiVision™ Optical System | Dual optics concept with robust Paschen Runge mount, multi-chip systems with temperature stabilization | Optimal choice between 3 variants to fulfill individual analytical needs |

| VUV Optics UV/VIS Optics | 130 - 200 nm, Ar-purged 190 - 620 nm, no purge | Outstanding performance with high resolution and low argon consumption Reliability meets low cost of ownership |

| Models | ||

| Q4 TASMAN 130 Q4 TASMAN 170 Q4 TASMAN 200 | λ: 130 - 620 nm λ: 170 - 620 nm λ: 200 - 620 nm | Best performance for N and O Full capabilities incl. C, P, S, Sb, Te Mastering non-ferrous metals analysis |

| Electrical Data | 100 – 204 V (± 10%), 50-60 Hz 16 A (240 V) or 25 A (100 V) slow blow fuse 600 W measurement, 50 W standby | Compatible with all worldwide power and current configurations |

| Dimensions and Weights | 54 x 80*) x 60 cm (W x D x H), ~75 kg | Compact benchtop system |

| *) 90 cm with optional active thermal control system |

Q4 TASMAN Resources

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)