SC-XRD Sources

METALJET MC

Taking home-source intensity to the next level – the METALJET MC breaks the 1012 barrier The METALJET MC for X-ray diffraction delivers the smallest and most intensive X-ray beam of any home lab X-ray source to meet the ever-increasing demands of modern structural biology including protein crystallography and Small Angle X-ray Scattering.

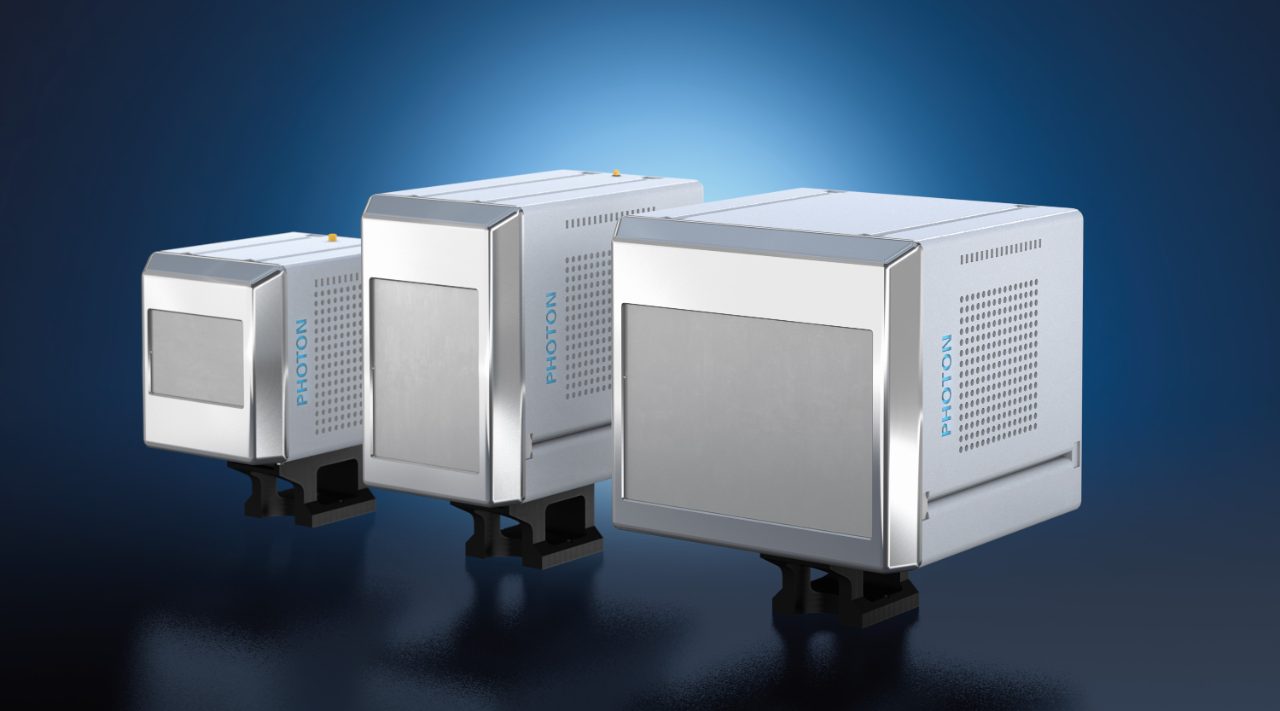

IμS DIAMOND II

The IµS DIAMOND II combines rotating anode performance with the comfort of an air-cooled sealed tube system. The IµS DIAMOND II is available for Copper (Cu), Molybdenum (Mo) and Silver (Ag) radiation.

IµS 3.0

The IµS 3.0 is the first-ever microfocus source designed from the ground up for crystallography.

Sealed Tube

Our water-cooled sealed tube X-ray source delivers a large top-hat-shaped beam with excellent intensity for large and medium sized crystals in chemical crystallography.

Taking home-source intensity to the next level – the METALJET MC breaks the 1012 barrier

The METALJET MC for X-ray diffraction delivers the smallest and most intensive X-ray beam of any home lab X-ray source to meet the ever increasing demands of modern structural biology including protein crystallography and Small Angle X-ray Scattering (SAXS). Consequently, the METALJET MC enables you to collect data on smaller, more weakly diffracting crystals.

The world’s strongest in-house X-ray source is now even more powerful: 250 W power load on the target, extended cathode lifetime with longer uptimes and further reduced maintenance requirements define the next generation, the new METALJET MC.

In the METALJET MC the solid target of conventional rotating anode generators is replaced by a high-speed jet of liquid metal that can accept a much higher power load. The result is an X-ray beam that is much brighter than traditional home sources.

While rotating anodes typically lose up to 40% of their intensity over a year of operation due to ablation of the anode surface, also known as anode roughening the METALJET MC always has a fresh, clean liquid metal anode surface. The METALJET MC’s intensity is stable over long time. Even after years of operation the anode delivers an intensity equal to the intensity on the first day of operation.

METALJET MC X-ray Source

Higher performance – smaller samples

To deliver such a small X-ray beam required technical innovation in the design of the X-ray optic with greater precision in the d-spacing of the multilayers. The HELIOS MC optics for METALJET transmits the X-rays to the crystal in a uniformly small diameter, greatly exceeding the intensity of conventional X-ray sources.

The METALJET MC is fully integrated into the D8 VENTURE cabinet, resulting in a small-footprint diffraction system. The source mounts directly on the goniometer ensuring easy and stable downstream alignment guaranteeing an excellent overall system precision.

By default, the D8 VENTURE with METALJET MC is shipped dual-port ready, with a second port ready for another diffraction experiment, e.g. for BioSAXS investigations.

The level of integration makes the difference between a MetalJet and the Bruker METALJET MC.

- Highest X-ray intensity due to exclusive patented liquid-metal-jet technology. One order of magnitude greater power load than conventional rotating anode X-ray sources.

- Unprecedented brightness resulting from the extremely high-power load capacity and smallest electron focus.

- Perfect spot quality is achieved through the high-brightness LaB6 cathode and smooth, self-regenerating, liquid metal target which provides exceptional spatial and emission stability.

- Lower noise as the shorter-wavelength gallium Kα X-rays (λ = 1.34 Å) result in reduced background scatter and higher detector efficiency.

- Lower running costs are ensured by the low power consumption, minimal cooling requirements, and the self-regenerating target.

- "Dynamic Adaptation Technology" delivers an even more stable X-ray beam with increased up-time and reduced service costs.

D8 VENTURE with METALJET MC achieves truly synchrotron-like X-ray intensities. For the first time, intensities above 1012 X-rays sec-1·mm-2 are possible in the home laboratory. Thus, the D8 VENTURE METALJET MC is the ideal solution for investigating your smallest, micron-sized samples.

Twice the intensity, proven reliability

The new Incoatec IμS DIAMOND II once more pushes the limits in microfocus source technology for crystallography:

- Twice the intensity for faster data collection from smaller crystals

- Five-year typical tube lifetime with an average intensity outperforming rotating anodes.

- Nearly instantaneous automated wavelength switching in dual IμS DIAMOND II configurations.

The IμS DIAMOND II incorporates two major technical innovations:

- Hybrid metal-diamond anodes with isotopically pure diamond permits a higher electron power density on the anode and hence a brighter X-ray source.

- New high-brightness cathode technology producing a more homogenous, higher current density electron beam to fully exploit the potential of the new isotopically pure diamond hybrid technology.

The IμS DIAMOND II - a strong family heritage

Since its introduction in 2006 more than 1700 IμS sources have been installed and over 96% of these are still operational. This makes the IμS both the world’s most successful and the most reliable microfocus source. The enhanced performance of the fifth generation IμS DIAMOND II is coupled with all the operational advantages which have made previous IμS generations so successful:

- Air-cooling for unrivalled long-term stability with minimized installation requirements (single phase power, no cooling water).

- Optimum anode take-off angle for crystallography for higher intensity at the sample and thus better data.

- Long tube lifetime, typically five years.

- No routine maintenance required.

Designed from the Ground up for Crystallography

The IµS 3.0 is the first-ever microfocus source designed from the ground up for crystallography. Conventional microfocus sources adapt technology that was originally developed for radiography (non-destructive testing) and are thus not optimal for X-ray diffraction.

The IµS 3.0 makes no such compromises: every aspect of the source is specifically designed and manufactured for X-ray crystallography.

This means that you get a much brighter beam than ever before: up to twice the intensity of conventional microfocus sources. The IµS 3.0 also features significantly better beam stability than conventional sources.

Best of all, the IµS 3.0 retains the legendary reliability and long tube lifetimes of the IµS family. New installations are backed by the industry leading 3-year warranty.

- Up to twice the intensity of conventional X-ray microfocus sources

- Completely air cooled

- Very low power consumption

- Very long tube lifetimes

- Very little decay of intensity with time

- Most stable X-ray output

- Hermetically sealed, He-purged optics

- High reliability, 3 year warranty

Available in the D8 QUEST and D8 VENTURE with Cu, Mo and Ag Kα radiation.

Large top-hat-shaped beam with excellent intensity

Our water-cooled sealed tube X-ray source delivers a large top-hat-shaped beam with excellent intensity for large and medium sized crystals in chemical crystallography. The source can be combined with a flat graphite monochromator for Cu and Mo radiation. The TRIUMPH monochromator is available for Mo radiation as an alternative to further increase the intensity. The sealed tube is powered by 3 kW highly-stabilized medium-frequency generator featuring an automatic monitoring of all important parameters as part of the DAVINCI concept.

Since both, tube and generator are water-cooled heat dissipation to the air is minimized.

- Automatic burn-in of X-ray tubes to facilitate maximum tube lifetime

- Ramp-up and ramp-down to stand-by of the X-ray generator by software

For smallest crystals in chemical crystallography higher intensity sources, such as the IμS 3.0, IµS DIAMOND II or the METALJET D2 PLUS are available. These sources also should be used for the investigation of protein crystals.

Resources

Brochures & Technical Notes

- Characteristics and Relative Performance of Molybdenum X-ray Sources for Chemical Crystallography

- Characteristics and Relative Performance of Laboratory X-ray Sources for Macromolecular Crystallography

- X-ray Detectors for Home Laboratory Macromolecular Crystallography: Does Size Matter?

- Good, Better, Best: Photon Counting, Integration and Mixed-mode Detection

- Advanced Large Area Indirect X-ray Detectors

- Charge Sharing in Pixel Array Detectors: Origins, Impact on Data Quality and Solutions

- New Developments in Pixel Array Technology: Hybrid Photon Counting and Charge-Integrating Pixel Detectors

- Design and performance of X-ray microfocus sources

Product Sheets & Application Notes

- Novel In-house Structure of a Cognate Chaperone- Toxin Complex: High Resolution Data from D8 VENTURE with IμS DIAMOND and PHOTON III M28

- When one crystal is not enough: Better Completeness with Multiple-Crystal High-Pressure Experiments

- D8 VENTURE METALJET - GPCR Crystallography Moves In-House: Structure of the Human Orexin-1 StaR® to 2.77 Å

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)