xSol High Temperature Stage

Nanomechanical characterization at elevated temperatures up to 800°C and beyond

The ability to understand nanoscale mechanical properties at high temperatures is imperative to developing materials capable of reliably performing in extreme operational environments. The Bruker xSol High Temperature Stage enables quantitative, accurate, and reliable nanomechanical characterization at elevated temperatures up to 800°C.

Unrivaled stability for quantitative and repeatable results

The proprietary stage design is constructed with a unique combination of low thermal expansion and thermally insulating materials to achieves high thermal stability and short stabilization times. Duel high precision resistive heaters are controlled by independent PID feedback-loops to heat the top and bottom of the sample. The heating element architecture forms a micro-environment within the stage’s interior with tight temperature control and uniformity. A proprietary probe design provides conductive and radiative tip heating for isothermal tip-sample contact. The micro-environment can be purged with customized gaseous atmospheres to prevent reactive chemistries on the sample surface, such as oxidation.

Compatible with a powerful suite of characterization techniques

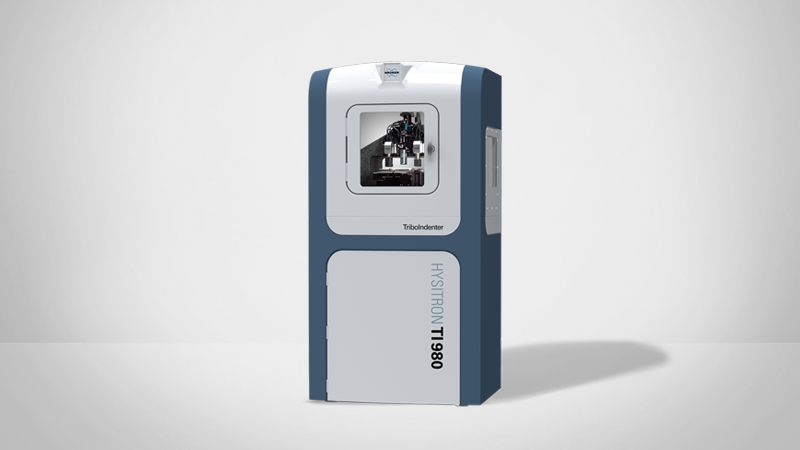

The Hysitron xSol stage is compatible with Bruker’s in-situ SPM imaging, nanoindentation, nanoscratch, nanowear and nanoDMA III techniques to obtain a comprehensive knowledge of nanomechanical and tribological behavior at elevated temperatures. Dynamic testing can be performed at various testing frequencies and temperatures to conduct time-temperature superposition studies of nanoscale volumes of material. Creep measurements over long time periods can be performed utilizing nanoDMA III’s reference frequency technique. Combining the xSol with accelerated property mapping (XPM) enables rapid testing and localized material properties to be thoroughly characterized and tuned for their intended operating temperature.