Silicon Quality Control

Silicon Quality Control

Elemental impurities and disruptions of the crystal lattice have a profound impact on the optical and electrical properties of Silicon. Therefore monitoring the quality in regards to foreign contaminations and size of Si-crystalites is a critical task. FT-IR and micro-XRF are ideal analytical tools to visualize large defects and crystallizes in such materials.

FT-IR Solutions for Silicon Quality Control

A whole range of materials can be investigated including in particular solutions for silicon QC according to ASTM/SEMI MF standards.

- Room temperature carbon and oxygen quantification for industrially produced silicon

- Determination of shallow impurities (B, P, As etc.) that significantly affect the electrical properties of Si

- Low temperature NIR photoluminescence for quantification of shallow impurities with unmatched sensitivity

CryoSAS:

Cryogenic silicon analysis system for low temperature silicon impurity analysis

INVENIO and VERTEX:

Next generation FT-IR spectrometers with high flexibility

Room Temperature Carbon and Oxygen Quantification in Silicon

FT-IR analysis of Carbon and Oxygen in Silicon is fast, sensitive, destruction free and therefore a widely accepted method of Si quality control.

Bruker has decades of experience in this field and based on the VERTEX series we offer the most powerful and up to date solutions.

- Room temperature quantification of substitutional Carbon in Si according to ASTM/SEMI MF1391

- Room temperature quantification of interstitial Oxygen in Si according to ASTM/SEMI MF1188

- Achievable detection limits <400 ppba

- Recommended sample properties: thickness 0.5 – 2.5 mm, double-sided polished, single crystal or polycrystalline

Low temperature Photoluminescence for Silicon QC

Low temperature NIR photo-luminescence (PL) enables the quantification of shallow impurities (e.g. B, P) in single crystal Silicon, according to ASTM/SEMI MFI1389.

Combining the unmatched sensitivity of the VERTEX 80 FT-IR spectrometer and a dedicated Si photo-luminescence module with cryostat, detection limits less than 1ppta are achievable.

- B, P and Al quantification in single crystal Silicon according to ASTM/SEMI MFI1389

- Trichlorsilane (TCS) quality control by PL of epitaxial Si layers deposited from TCS via CVD

- Various options such as cryostat automation, dedicated software for Si QC by photoluminescence, calibration samples and 2nd additional excitation laser

Application Examples

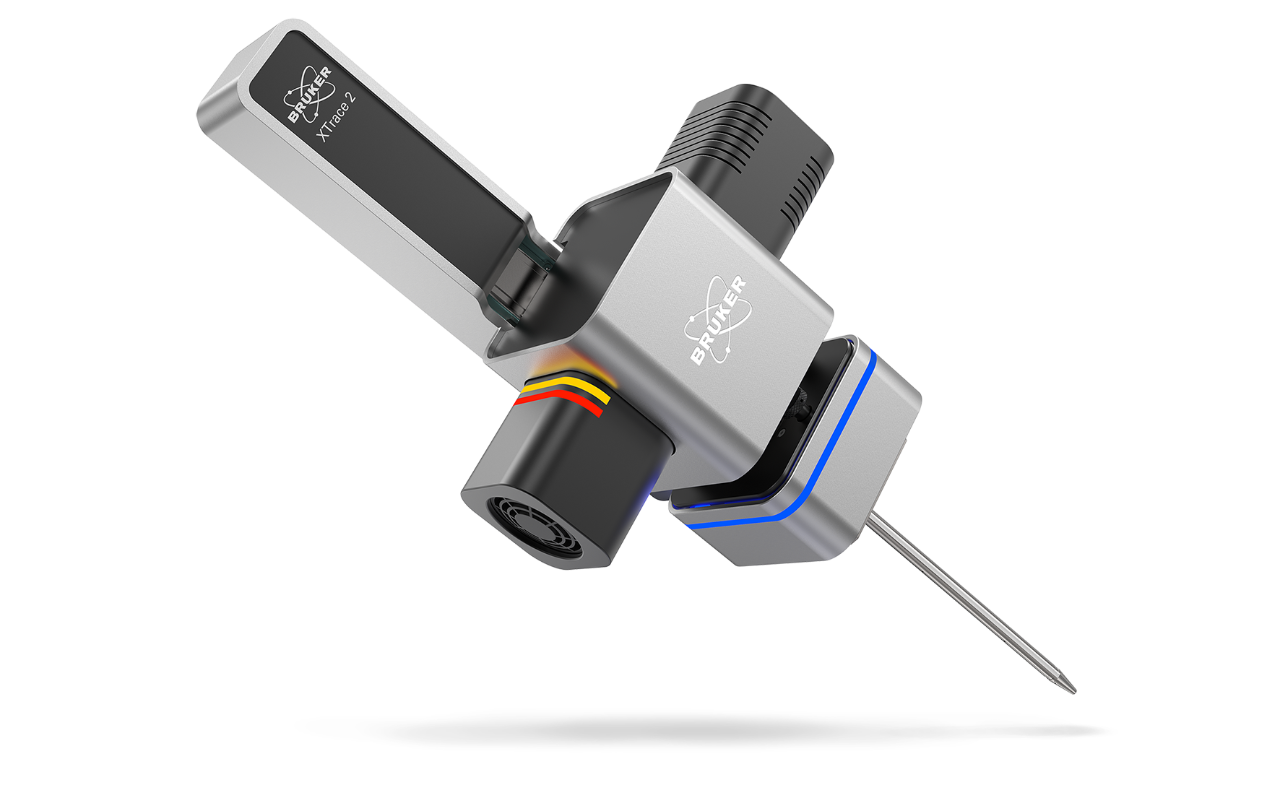

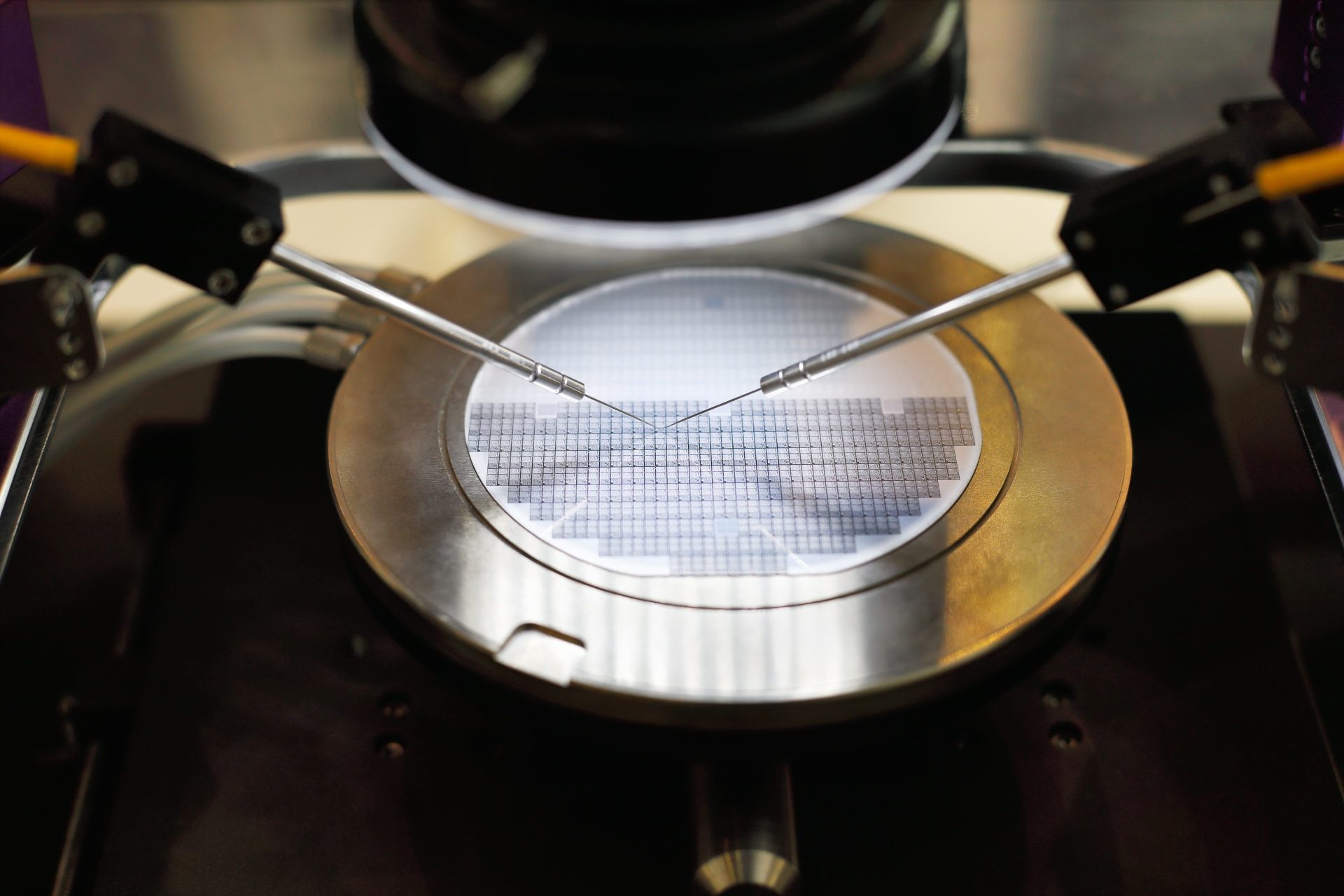

Fast Crystal Domain Mapping Using Energy-dispersive micro-XRF

In energy-dispersive XRF, Bragg diffraction peaks are often considered a bothersome artifact interfering with the fluorescence information. However, these Bragg peaks, as they are related to crystal orientation, provide additional information on the nature of the sample. Here, we describe how the M4 TORNADO can be utilized to visualize crystal domains. This information is crucial to evaluate the quality of single crystals as well as the properties of polycrystalline materials. This principle can be used to identify sub-grain misorientation in single crystals as well as crystallite dimensions within multi-crystalline samples.

Read also this related publication: