Copper Ore Mineralogy

Porphyry copper ore is challenging X-ray mineralogy. The mineralogy of the ore, concentrates and residues is complex. Twenty or more minerals are to be quantified in most of the samples. Peak overlap is massive and may mask minor phases. Clays and other layered material make a reproducible sample preparation difficult.

From Mine to Metal

These days, analytical service laboratories and the world´s biggest copper mines rely on Bruker X-ray technology, software and application expertise. They x-ray hundreds of blast-hole and process samples per day with turnaround times of 24 to 36 hrs from sampling to the result. Typical materials studied by XRD are:

- Exploration drill cores and cuttings

- Blasthole drill splits

- Mill feeds, concentrates and tailings

- Leach pile feed and residue samples

A major cost factor in a concentrator plant is grinding. Knowing about the rock hardness helps saving electricity consumption of the mill but also to reduce wear of the grinding consumables. It has been shown that a mechanic rock property (the so-called bond work index (BWI)) scales with predictions derived from the concentration of hard minerals (quartz, feldspar and plagioclase). Those hard rock minerals can easily be determined with XRD. The related annual savings of a larger mine exceed the costs of an X-ray laboratory by far. (Source: Mining Magazine (March 2015) p 38-40).

Properties relevant to extracting Copper from the rock solely depend on the type of minerals present in the specimen and not the chemistry. Nowadays, XRD together with NIR and scanning electron microscopy allow quantitative mineralogy analysis as quick as chemical analysis. New insights from mineralogy support block-modeling of the ore-body, mine planning and operation, metallurgical testing and processing.

The ore characterization lab may anticipate ore response to processing conditions. However, detrimental minerals have huge financial impacts. Swelling clay and kaolinite may prevent the flow of liquids within the leach pad. Calcite consumes acid that is reduces the extraction of the metal. Agglomerations of material may be related to the presence of clays and mica. Other minerals disrupt flotation.

XRD helps addressing all those issues. It identifies the minerals known to be troublesome and monitors their concentrations.

The Quantitative X-ray Mineralogy Workflow

The large number of samples that typically is investigated in a larger Copper mine calls for automation. Standard procedures ensure consistency in the sample preparation, measurement and during data evaluation. A typical workflow consists of

- Sample preparation: The samples run through primary and secondary crushers and mills until a grain size of ideally about 10 microns is achieved. The resulting powder is still is very sensitive to aligning in preferred directions. Therefore, soft pressing and/or back-loading are applied in the automated sample preparation equipment.

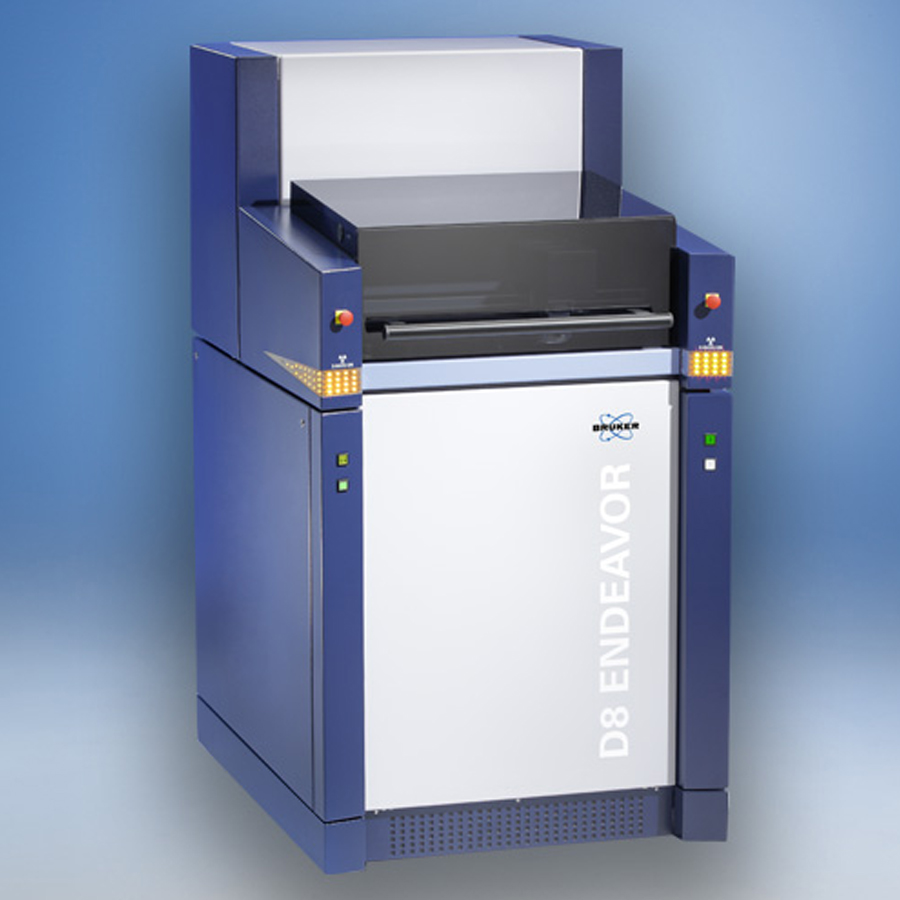

- Best possible XRD data are achieved using the D8 ENDEAVOR Minerals diffractometer, equipped with the energy dispersive fast LYNXEYE XE-T detector and Dynamic Beam Optimization.

- Mineral species are identified using DIFFRAC.EVA together with a suitable database. For quantitative analysis DIFFRAC.TOPAS provides unique tools that allow the evaluation of those extremely complex samples. This includes the use of fundamental parameters for peak modeling. It decouples the XRD resolution from sample properties with a minimum of free parameters. This together with smart limits reduces correlations and provides a unique solution.

- Given the complexity of the analytical task a results reconciliation using the minerals assay from Scanning Electron Microscopy and Scanning X-ray Fluorescence is performed and a combination of results with chemical assay data is done. Further the results of X-ray Mineralogy are combined with Near Infrared Spectroscopy, which is a fast meansof quantifying total clay, hydroxides and other soft minerals.