Monitoring silica workplace dust exposure

Why monitoring silica dust?

Lung cancer and other health issues are known to be associated with occupational exposure to breathable crystalline silica, SiO2. This makes silica dust, or free silica, the 2nd largest cause of occupational cancer after asbestos.

Who is affected?

Silica is a typical component of soil and rocks but is also contained in foundry materials or concrete. Clear exposure/response relations were reported for e.g. miners, diatomaceous earth and construction workers, granite, pottery, refractory bricks, or foundry workers.

Occupational exposure to respirable silica is a preventable health hazard. Exposure limits were issued by several national authorities and therefore, concentrations of silica are to be monitored.

Why X-ray powder diffraction?

X-ray powder diffraction (XRD) is capable of distinguishing the polymorphs of crystalline silica (quartz, cristobalite and tridymite). Furthermore, XRD may account for the interference with other minerals that may additionally be present at the workplace.

Why choose Bruker XRD?

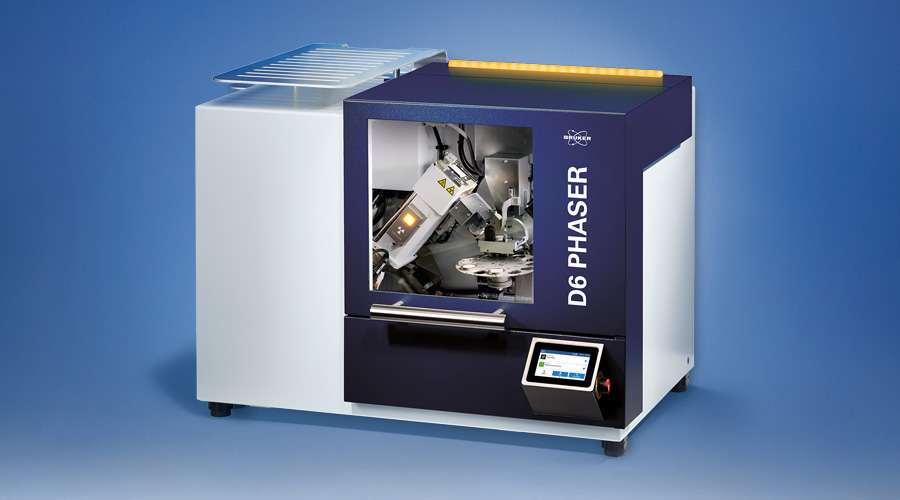

Bruker offers the complete XRD solution starting with filter sample holders for different filter types (32 and 25 mm diameter), a variety of XRD machines ranging from the benchtop D6 PHASER to the laboratory floor standing D8 ADVANCE and the high performance industry grade D8 ENDEAVOR.

The D8 ENDEAVOR is equipped with Dynamic Beam Optimization and the LYNXEYE XE-T detector. This setup ensures highest count rates at best peak/background ratio paired with ease-of-use.

The DIFFRAC.DQUANT software is used to establish norm compliant drift corrected calibrations, evaluate unknowns and to report the results directly to the laboratory LIMS system or to the internal instrument database. It fully supports absorption correction as requested by NIOSH 7500 or segment calibrations. The measurement systems and evaluation software provides audit trail and tamper proof data handling for working in FDA 21 CFR Part 11 controlled environments.

X-ray intensity changes

Calibration in DIFFRAC.DQUANT