Welding Industry

Avoid costly failures

Highlights on Welding

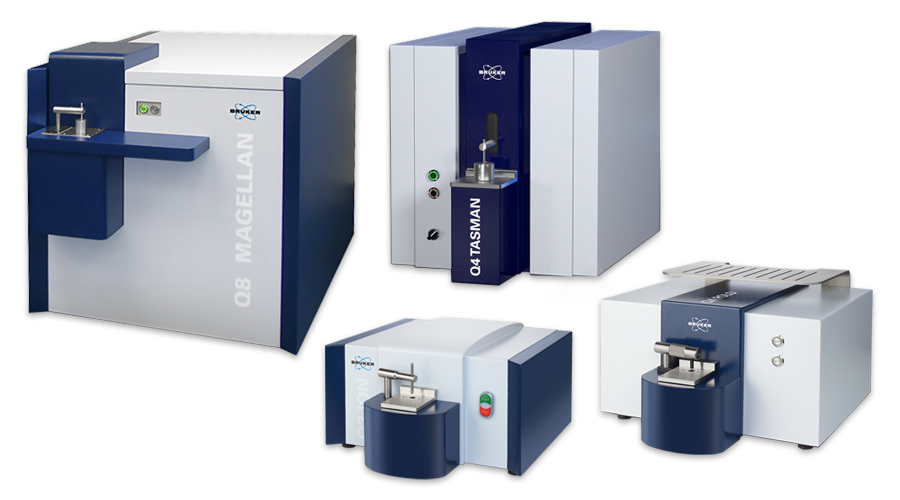

Bruker offers a wide portfolio of solutions for all tasks within the welding industry ranging from incoming inspections of raw materials, welding rods and consumables to all kinds of pre-, in- and post-welding inspections. For example, whereas OES or XRF instruments deliver information on the exact chemical composition of the weld, micro-XRF techniques, EDS and EBSD detectors on electron microscopes, qualify and quantify welding defects on the micrometer scale such as inclusions, the lack of fusion or local deformations.

Hydrogen-induced damage is a wide-spread and dreaded phenomenon. During welding, hydrogen is generated from the dissociation of water vapor (e.g. humidity) or hydrocarbons in the welding arc, and the molten metal can rapidly pick up hydrogen. Once in the weld metal, hydrogen atoms can diffuse swiftly into the heat-affected zone of the base metal as diffusible hydrogen. During cooling and phase transformation of the matrix, the residual hydrogen accumulates at microstructural dislocations and voids as molecular hydrogen, resulting in localized tensile stress adding to the residual tensile stresses. Diffusible hydrogen causes hydrogen induced cracking (also known as cold or delayed cracking), where components fail under the influence of mechanical stress - suddenly and without prior indication.

Welding Analysis Using Handheld XRF: The Best Nondestructive Material Identification for Welds

Welding analysis using handheld XRF is a fast, nondestructive testing (NDT) technique to confirm the proper filler material is being used to weld alloys, and to help avoid defects. Using the correct grade of alloy is crucial to creating a successful weld. Despite certification, alloy mix-ups still occur. Verification of the appropriate filler material can be obtained with the S1 TITAN in seconds.

Structural integrity, confidence in welds

In an environment where structural integrity relies on welding, it is critical to have confidence in the welds and welding material. Analyze incoming alloys before any welding takes place. Verify in-situ welds during inspection procedures.

Benefits of XRF for weld analysis

- Decipher the optimum filler by analyzing the elememtal components in the weldment

- PMI (Positive Material Identification) incoming weld material to confirm it matches specifications prior to installation

- Alloy verification of completed joints during final inspection

- Verification of in-process material and all components; plates, pipe, sleeves etc.