Process Mineralogy

Process Mineralogy

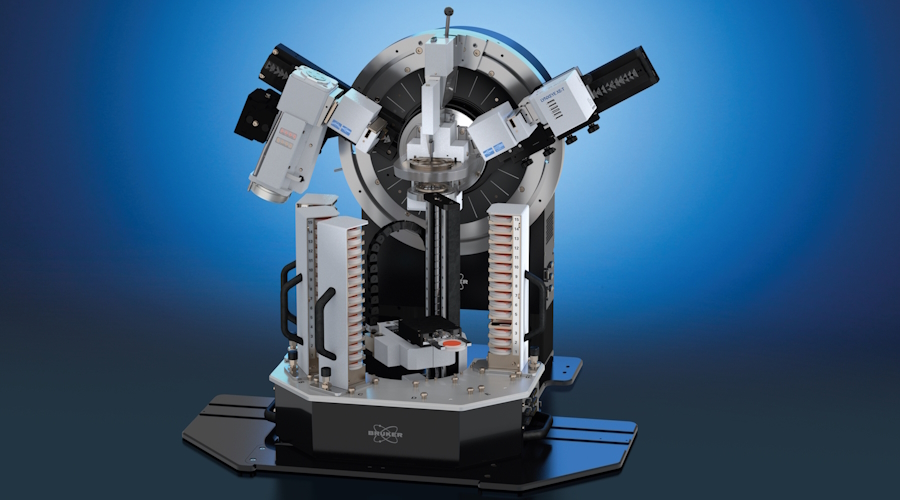

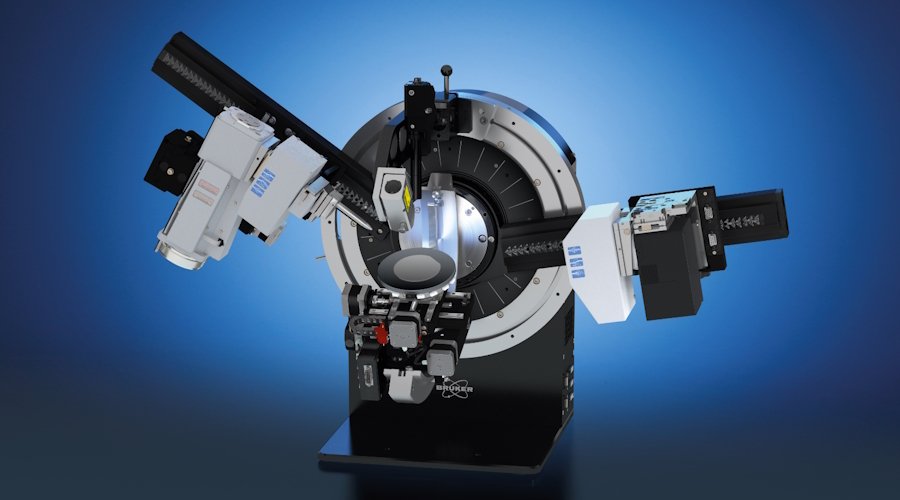

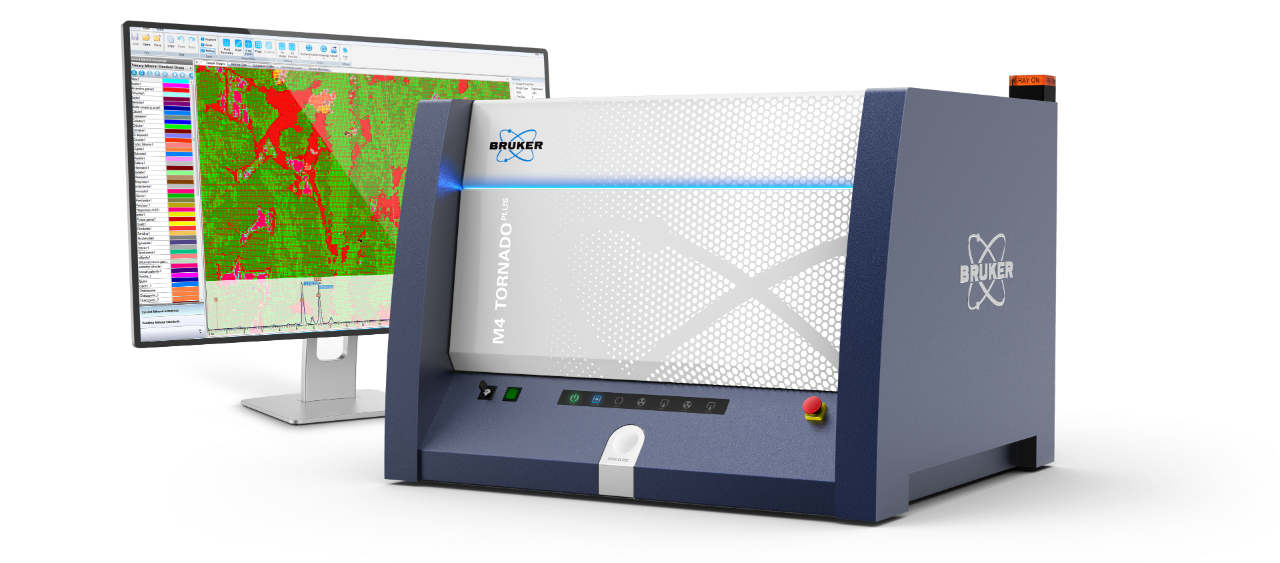

Process Mineralogy is the characterization of the minerals in an ore to optimize the process of recovering valuable minerals from the waste rock or gangue. Bruker has a range of analytical solutions that can provide mineralogical information to optimize recovery.

Ore Characterization

More and more emphasis is placed on understanding the ore body in as much detail as possible before mining commences. This approach is not only driven by a need to reduce risk and cost, but by the fact that ore bodies are becoming increasingly lower-grade and complex. Mineralogy is crucial in understanding the variability of the ore body, and also to highlight problematic minerals that can impact on grinding, flotation and/or leaching. Hazardous mineral species need to be identified to mitigate any problems during the remediation stage.

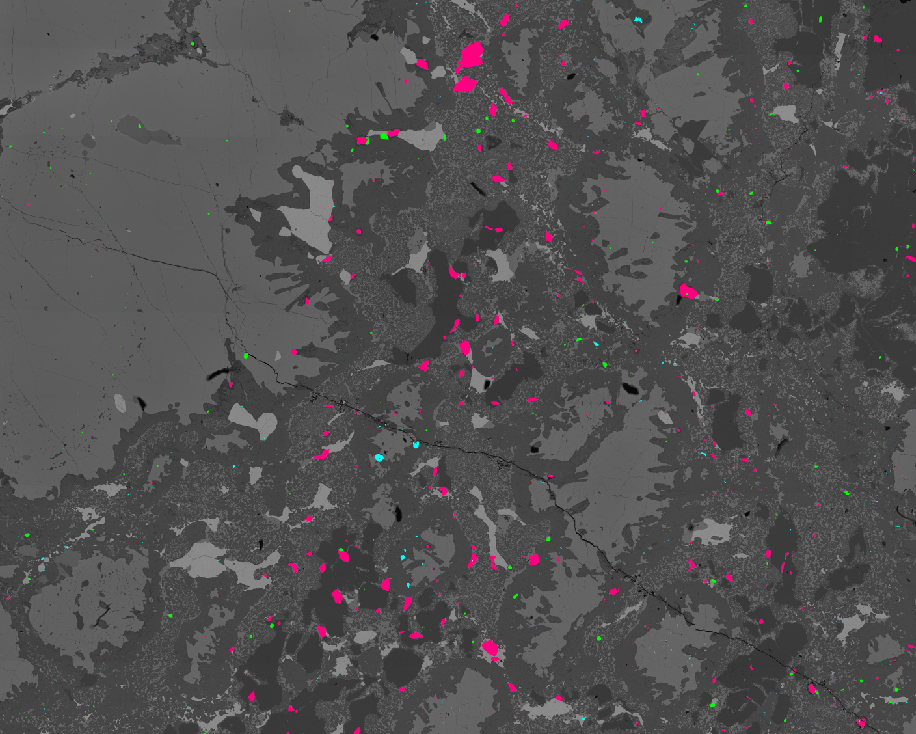

Detailed mineralogical information such as texture (grain size and grain boundary relationships) is important to understand how difficult it would be to separate valuable minerals from gangue and determine the viability of a project. Bruker offers solutions to perform ore characterization from drill core samples to pilot plant feed products.

Plant Design

To effectively design a plant it is necessary to know the mineralogy of the feed. Bruker offers solutions that can provide mineralogical information from basic to advanced levels. Bulk mineralogy can be indicative of hardness. The presence of certain minerals, such as clays or carbonates can be indicative of future difficulty in flotation or leaching.

Add to this characteristics about the textural relationship (size, grain boundaries) of the valuable mineral with gangue and recommendations on grinding can be deducted. Further detailed quantitative analysis on selected mineral phases can highlight the presence of elements that could be problematic due to penalty elements or hazardous components such as arsenic and mercury.

Plant Optimization

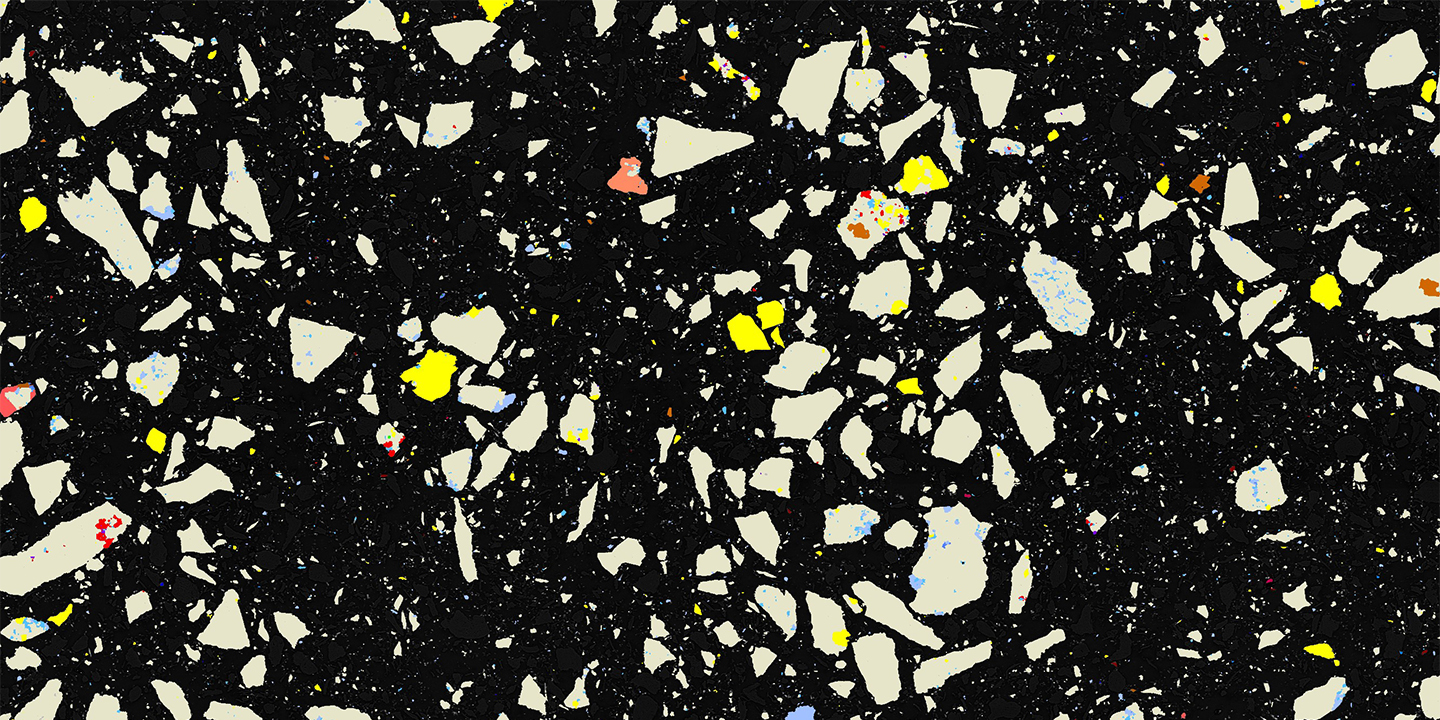

Detailed mineralogy is key to ensure that the processing plant maintains optimum efficiency as the plant feed or flow sheet changes. Bruker has the solutions to not only determine the mineralogy, but the ability to track the degree of liberation of target minerals in the feed and products. At the same time data, such as the grain size and association of any mineral, can be calculated on statistically sound data. Such detailed information is useful to understand deleterious minerals and limit the occurrence of penalty elements in the concentrate.

Tailings Characteristics

Although the tailings are regarded as waste material, the mineralogical characterization is equally important. Tailings characteristics can vary substantially and are not only influenced by ore mineralogy changes, but also by the physical and chemical process used to extract the valuable minerals.

Detailed knowledge of the tailings characteristics is vital to ensure that valuable materials are not unnecessary loss, and equally important to determine the behavior of the tailings once stockpiled. Environmental standards are becoming more demanding to ensure that tailings should not cause harm to people or the environment.

Publications Related to Process Mineralogy

- 2020 - Rare Metals: Process mineralogy of Dalucao rare earth ore and design of beneficiation process based on AMICS

- 2020 - Mining, Metallurgy & Exploration: Chemical and Mineralogical Characterization of Malaysian Monazite Concentrate

- 2019 - China Geology: A new type U-Th-REE-Nb mineralization related to albitite: A case study from the Chachaxiangka deposit in the northeastern Qaidam Basin of China

- 2019 - Hydrometallurgy: Enhancing rare-earth recovery from lamp phosphor waste

- 2017 - Geoscientific Instrumentation, Methods and Data Systems: Automated mineralogy based on micro-energy-dispersive X-ray fluorescence microscopy (µ-EDXRF) applied to plutonic rock thin sections in comparison to a mineral liberation analyzer

- 2016 - Gold Ore Processing: Chapter 6 - Geometallurgical Characterization and Automated Mineralogy of Gold Ores

- 2009 - Measurement Science and Technology: Total reflection of x-ray fluorescence (TXRF): a mature technique for environmental chemical nanoscale metrology