What Can AFM Do for Polymer Research?

Explore the Latest Developments in AFM Analysis of Polymers

In this webinar, speakers present the latest in AFM analysis for polymeric applications and research. Also included is a two-part practical in-lab demonstration of the techniques and modes discussed.

Webinar Summary

Join us for an engaging discussion on the latest in AFM analysis for polymeric applications and research. Along with the presentations from our guest speakers, this recording features in-lab demonstrations of the techniques and modes discussed.

Watch our speakers' selected presentations to learn about:

- High-resolution electrical characterization with KPFM and TUNA providing insight into material performance and helping to optimize organic photovoltaics and Li-ion batteries

- How AFM can be used to obtain the mechanical properties and chemical information for development of new materials and for troubleshooting production issues

- Strengths and weaknesses of common AFM modes when applied to polymers and composites

- Practical considerations such as probe selection and system calibration

Find out more about the featured AFM products and technologies in this webinar:

| Presentation Length | Presentation Title | Presenter | Abstract |

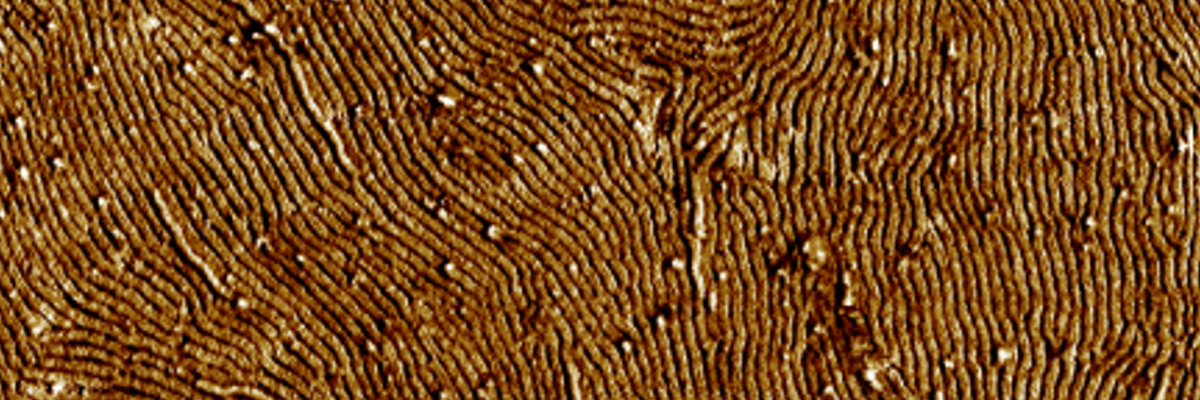

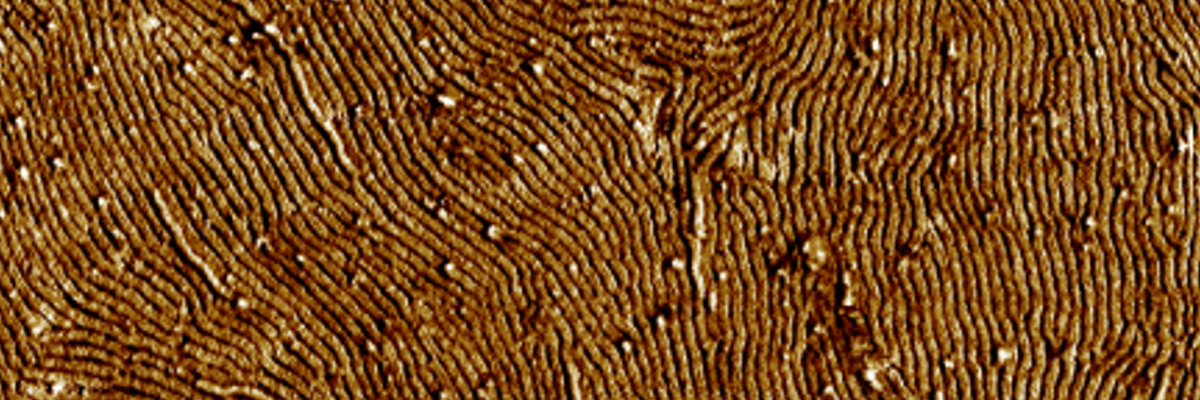

| 35 min | A Selection of Modes and Methods for SPM Research of Polymers | Bede Pittenger | Scanning probe microscopy (SPM) has many benefits over alternative techniques for studying polymeric materials. The sharp apex and precise force control provided by SPM enables researchers to probe heterogeneous samples with resolution down to the nanometer level where single molecules can be observed. Many different material properties and behaviors can be studied by measuring a signal (e.g., force or current) localized by the probe apex while changing instrumental conditions (e.g., Z position or bias). SPM works over a wide range of temperatures, and in both air and liquid, allowing researchers to select the most interesting environment for their experiments and to do comparisons between measurements under different conditions. In this talk, the speaker introduces SPM modes that are often used in polymer research and describes their strengths and weaknesses. He discusses methods for measurement of polymer dynamics, high resolution mechanical property mapping, probing the time-dependent viscoelastic behavior of polymers, nano-electrical measurements with data cubes, and temperature-dependent measurements. The speaker additionally discusses practical matters of interest to polymer researchers such as the system calibrations needed for quantitative measurements, probe selection, and sample preparation methods. |

| 30 min | Atomic Force Microscopy in the Polymer Materials Industry | Greg Meyers | In this segment, the speaker presents a perspective of AFM capability development coupled with the needs of industrial polymer materials characterization. This includes fundamental studies of polymer behavior, polymer materials development, and troubleshooting issues. For example, AFM has replaced much of the TEM workflow for sizing of phases in polymer blend development since no heavy metal staining is required. Further time savings come from the ability to automate many of the steps involved in sample preparation, image acquisition, and image analysis. A more recent innovation in AFM technology has been chemical functional spectroscopy and mapping using AFM-IR, where AFM is used to detect infrared absorption on the nanoscale via photothermal expansion. This added dimension of chemical contrast now allows AFM to see the chemistry in the morphology. |

| 13 min | Recent Developments with Live Demo - PART 1 | Mickael Febvre | - |

| 35 min | Nanoscale Electrical Characterization of Organic and Hybrid Materials for Energy Harvesting Applications | Philippe Leclere | The recent development of alternatives to fossil fuels will play a crucial role in global electricity generation and should be one of the global strategies to reduce CO2 emissions. To develop efficient and competitive modern electronics from semiconducting materials for energy conversion and storage, it is essential to understand the relationships between molecular architecture, supramolecular organization, microscopic morphologies and optoelectronic properties. Using AFM-derived techniques (such as Conducting AFM, Kelvin Probe Force Microscopy - KPFM), local electrical properties can be measured (together with the morphological and mechanical characterization of the samples) helping to optimize device performance. In this presentation, the speaker presents examples of how the lateral resolution in KPFM and in photo(conducting) AFM can allow a direct visualization of the carrier generation at the donor-acceptor interfaces and their transport through the percolation pathways, among other examples. |

| 11 min | Recent Developments with Live Demo - PART 2 | Senli Guo | - |

Speakers

Bede Pittenger, Ph.D., Sr. Staff Development Scientist, AFM Applications, Bruker Nano Surfaces

Dr. Bede Pittenger is a Senior Staff Development Scientist in the AFM Unit of Bruker's Nano Surfaces Business. He received his PhD in Physics from the University of Washington (Seattle, WA) in 2000, but has worked with scanning probe microscopes for 25 years, building systems, developing techniques, and studying properties of materials at the nanoscale. His work includes more than thirty publications and three patents on various techniques and applications of scanning probe microscopy. Dr. Pittenger's interests span topics from interfacial melting of ice, to mechanobiology of cells and tissues, to the nanomechanics of polymers and composites.

Dr. Greg Meyers

Fellow, Core R&D - Analytical Science, The Dow Chemical Company, Midland, MI

Gregory F. Meyers, PhD, is a Fellow in Core R&D – Analytical Sciences at The Dow Chemical Company. He has technical leadership for strategic planning within the Surface & Interface Characterization group. His technical area of expertise is in scanning probe microscopy where he established Dow's global AFM capability. Greg was a co-principal investigator along with Dr. Craig Prater (formerly of Veeco, Inc.) on a 3year, $13MM joint NIST ATP project to develop quantitative nanomechanical measurements based on an atomic force microscopy platform. He has also participated in the development of Bruker (Anasys Instruments) NanoIR platform (2010 R&D 100 winner). He is the author or co-author of 1 textbook, 4 book chapters, 59 publications, and 2 patents. Greg obtained a BA degree in chemistry from Bowdoin College in 1979 and a PhD degree in inorganic chemistry from Texas A&M University in 1985.

Prof. Dr. Philippe LECLERE

Associate Professor, University of Mons

Philippe Leclère, Ph.D. is a Research Director of the Belgian National Fund for Scientific Research (FRS – FNRS) and associate professor at UMONS. His research interests include characterization of the morphology, electrical and mechanical properties of polymeric systems such as blends, nanocomposites, block copolymers, liquid crystals, and supramolecular (nano)structures. These systems find applications in organic electronics and energy harvesting devices (field effect transistors, organic light emitting diodes, (hybrid) photovoltaic solar cells, batteries, nanogenerators and (bio)sensors), in smart coatings as well as biomimetic polymer-based materials. In addition, Philippe has been active in development and validation of novel SPM techniques and methodologies to quantitatively determine mechanical, thermal, electrical and the “coupled” properties (such as piezoelectricity, flexoelectricity and thermoelectricity) of polymeric and hybrid materials at the nanoscale. He is author of about 200 papers (h-index of 42) in the field and gave more than 300 talks around the world. He is currently the President of NanoWal (the Wallonia Network for Nanotechnologies) and Vice-President of the Royal Belgian Society for Microscopy.

Senli Guo, Ph.D., Application Scientist, Bruker

Senli earned his Ph.D. in physical chemistry from Duke University (2009) and spent two years in the Center for Nanophase Materials Sciences (CNMS) at Oak Ridge National Lab as a postdoc before joining Bruker as an applications scientist in 2011. All of Senli’s research is about AFM-based methodology developments to address various nanoscience research, ranging from single-molecule interactions to lithium-ion battery electrode properties.

Mickael Febvre, Ph.D.

Application Manager, Bruker EMEA