Nanoindentation on Metals

The Stress-Strain Relationship: Theory & Experiments

Nanoindentation hardness and reduced modulus values provide vital information on the stress-strain relationship of materials and, by extension, their expected behavior during manufacturing and use.

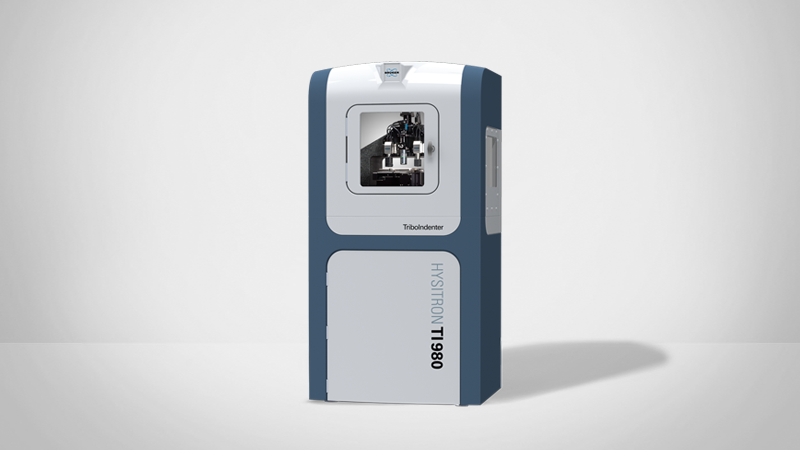

This workshop focuses on discussing and demonstrating different theoretical and experimental approaches for deriving the stress-strain relationship in nanoscale indentation and compression experiments. The session recording includes a technical demonstration of the TI 980 TriboIndenter, which showcases

- Indentation and compression testing of metals;

- Analysis of stress-strain relationship of metals; and

- High load spherical indentation.

Quantifying Hardness and Elastic Deformation of Metals

The stress-strain relationship of materials provides vital information on their mechanical properties and enables a prediction of their behavior during manufacturing and use. It also characterizes deformation behavior during elastic loading, from yield at lower stress levels to work hardening and ultimate failure at higher levels. The relationship is typically determined in tensile tests on macroscopic samples.

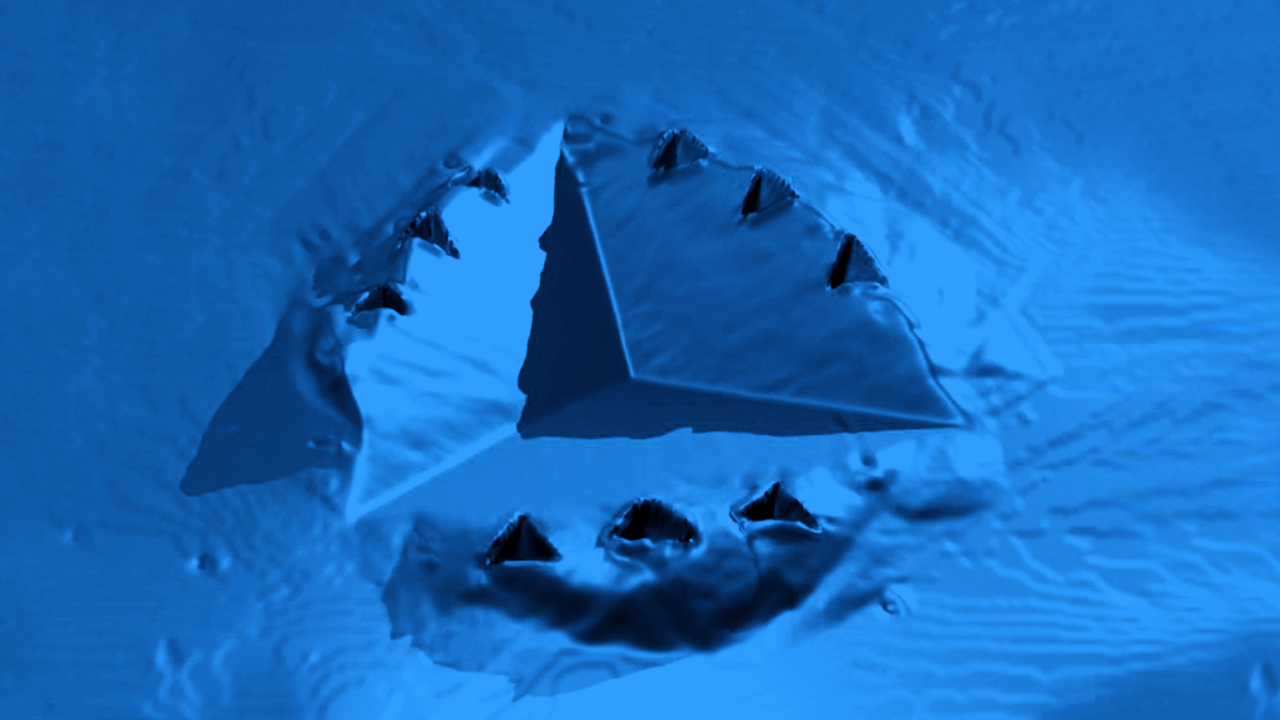

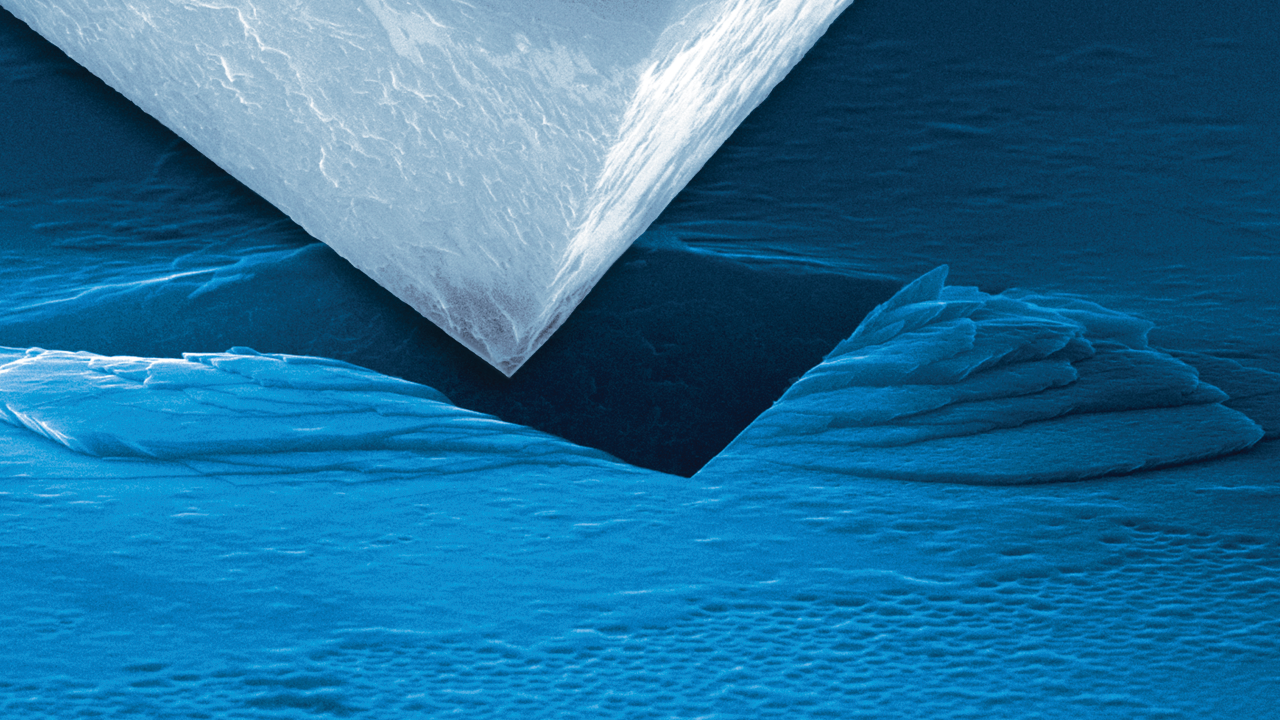

Nanoindentation hardness and reduced modulus values are directly related to a material’s stress-strain relationship. However, in hardness tests, the deformation zone is non-uniform, unlike tensile tests that produce uniform stress and strain.

In this webinar, our invited speaker Dr. André Clausner, Fraunhofer Institute for Ceramic Technologies and Systems (IKTS), Germany, will provide an overview of theoretical approaches to this problem and discuss possibilities and pitfalls. We will demonstrate different experimental approaches for deriving the stress-strain relationship in nanoscale indentation and compression experiments on metals and metallic surfaces using the TI 980 TriboIndenter.

Find out more about the technology featured in this webinar or our other solutions for investigating the nanomechanical properties of materials:

Featured Products and Technology

Speaker

Dr André Clausner

Fraunhofer Institute for Ceramic Technologies and Systems (IKTS), GermanyDr. André Clausner, a specialist in the evaluation of methods for determining yield stress in nanoindentation, is head of the department of Nanoanalysis and Microelectronic Materials at the Fraunhofer Institute for Ceramic Technologies and Systems, Germany. He has extensive experience in the performance of experiments on and the simulation of (nano/micro-) the mechanical behavior of materials. He is also an expert on characterization methods for the reliability testing of microelectronics, making him a much sought-after specialist in this field of science. André Clausner has (co)authored over 40 papers, is a Technical Committee Member, coordinates symposiums, and is a reviewer for leading conferences and journals.