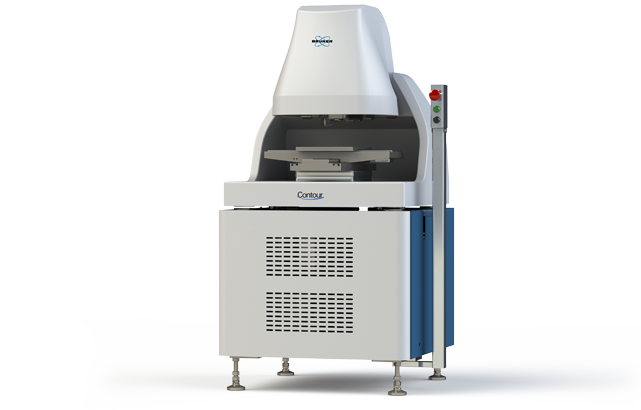

ContourX-1000

ContourX-1000 3D Optical Profilometer

The ContourX-1000 floor-standing white light interferometer (WLI) makes obtaining quality 3D areal surface texture and roughness measurements easy and fast. Incorporating 30+ years of innovation and our latest proprietary software and technology, this metrology system provides the rapid time-to-results and repeatability that Bruker's optical profilers are known for, with increased throughput and even greater operator ease.

With full automation capabilities, a straightforward user experience, and streamlined measurement setup and analysis recipes, the ContourX-1000 delivers the most accurate and precise metrology on almost any surface, by any operator, even in multi-user high-volume production facilities.

Next-Generation, Industry-Focused 3D Surface Measurement Solution

Equipped with Bruker-exclusive interferometry technology and capable of complete automation, the ContourX-1000 extends the unmatched measurement and imaging capabilities of our ContourX profilometry systems to include almost any development and production application.

Only the ContourX-1000:

- Provides fast and versatile production-floor metrology with exclusive tip/tilt head, dual-light source, and advanced automation;

- Ensures extreme accuracy and reliability with self-calibrating laser and integrated vibration isolation; and

- Integrates our most user-friendly measurement and analysis software with guided, simplified routines and recipes.

The Most Accurate and Precise Metrology on Almost Any Surface, by Any Operator

Obtaining quality 3D areal surface texture and roughness measurements is now easier and faster than ever with the ContourX-1000.

Laser Focus World visited us at SPIE Photonics West 2023 to discuss ContourX-1000's next-generation design. Watch the video spotlight or contact us to learn more about this self-calibrated, fully-automated solution for research and production.

Latest Optical Profiling Hardware Advances

The ContourX-1000 is equipped with a variety of unique and innovative hardware. Its next-generation design enables rapid optimization and maximum reproducibility for almost any development and production application, even in high-throughput and noisy environments.

Key features include:

- Patented tip/tilt head;

- Proprietary dual-LED light source;

- Automated turret and stages;

- Selection of wafer chucks;

- Proprietary internal laser reference; and

- Integrated vibration isolation.

▲ Patented tip/tilt head (contour family brochure)

Powerful Automated Measurement and Analysis

ContourX-1000's integrated, operator-friendly features and Advanced Production interface allow rapid collection of quality, gage-capable measurements with minimal user intervention. This eliminates the complexity, extended time-to-result, and operator inconsistencies that are inherent to manual setup, acquisition, and analysis.

Key features include:

- Automated measurement and analysis recipes;

- New one-click Advanced Find Surface with auto-focus and auto-illumination;

- Automatic determination of optimal measurement parameters with the self-adapting USI measurement mode;

- Guided VisionXpress interface;

- Automatic Pattern Alignment;

- Auto-intensity, auto-saving, auto-stitching, and more.

▲ Automation graphical user interface (GUI) with wafer map

Industry-Diven Solutions

ContourX-1000's unique combination of advanced hardware and software integrations enable highly precise, gage-capable, quantitative 3D surface characterization for a great variety of surfaces across a wide range of applications and industries -- including critical dimension metrology and many more.

Bruker's Vision64 Instrument Control and Analysis

ContourX-1000 is powered by Vision64® software, the industry’s most functional and user-friendly graphical user interface. This full-featured software includes:

Advanced Find Surface

The Advanced Find Surface feature enables any user to obtain quality results regardless of operator experience level, even in multi-user environments.

It not only enables auto-focus, but also adjusts key illumination parameters such as the intensity of the LED ring light. This allows uncompromised metrology on varied material surfaces with improved user experience, extreme operator ease, and faster time-to-result.

VisionXpress

Between the easy-to-use VisionXpress™ interface with its standard test library for multi-user environments, the award-winning full-featured Vision64 interface for advanced setup and automated analysis, and the Advanced Production interface for ultimate automation with minimal user intervention, you can select the most suitable solution for your unique metrology needs, without compromise. This unique capability enables uncompromised metrology on any surface, with increased throughput.

Universal Scanning Interferometry

The adaptive surface intelligence of USI mode automatically adjusts algorithm parameters for optimum results on different surface textures in the same field of view, even on surfaces with differing contrast, intensity, and heights. This ability to automatically sense the type of surface and provide the most accurate areal metrology makes it one of the easiest and most robust measurement methods for almost any surface, transparent to opaque, with a vertical range up to 120 µm.

ContourX: Four Decades of Wyko® and Bruker Technological Advances

ContourX systems utilize advanced metrology algorithms to optimize the capabilities of white light interferometry (WLI). The result is the highest degree of vertical resolution even at low magnification. This enables researchers and engineers to quickly obtain extremely accurate and statistically relevant data with results from large measurement areas.

ContourX profilometers achieve industry-leading capability and utmost customer satisfaction with:

- Most optimized WLI technology for surface metrology;

- Unmatched vertical resolution over a large field of view; and

- Fastest time-to-results with uncompromised precision and accuracy; and

- Best-in-class reliability and repeatability.

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.