nanoDMA III - Dynamic Nanoindentation

Quantitative nanoscale depth-profiling and viscoelastic property measurements

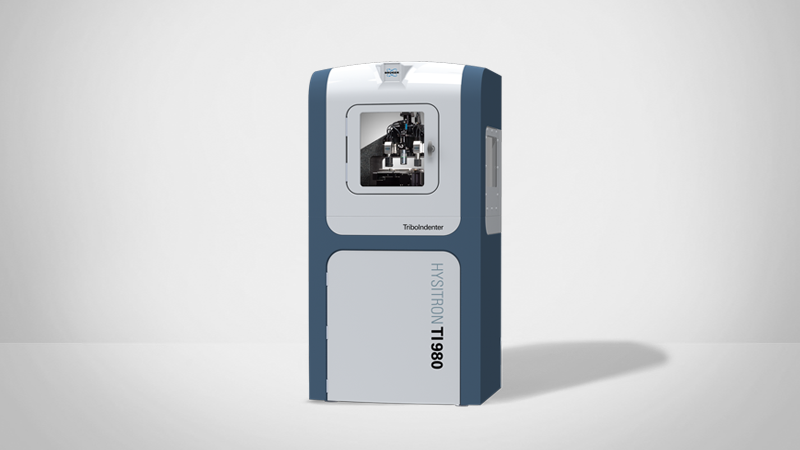

Bruker’s nanoDMA III (nanoscale Dynamic Mechanical Analysis) is a powerful new dynamic testing technique used to perform nanoscale mechanical property measurements. nanoDMA III is equipped with newly developed CMX control algorithms to provide a truly continuous measurement of mechanical properties as a function of depth into a material’s surface. CMX provides a quantitative and truly continuous measurement of mechanical properties — including hardness, storage modulus, loss modulus, complex modulus, and tan delta — as a function of indentation depth, frequency, and time.

Powerful Nanoscale Dynamic Characterization

High bandwidth transducer and control electronics are fully optimized for nanoscale dynamic testing and provide industry-leading performance, sensitivity, and a broad dynamic range. Hysitron’s unique coupled AC/DC force modulation routine enables true nanoscale mechanical characterization and is not subjected to the slow feedback response times that plague other nanoscale dynamic stiffness techniques. nanoDMA III incorporates a unique reference frequency technique for thermal drift correction during the course of an experiment, enabling long-duration frequency sweeps and creep tests to be reliably performed at the nanoscale.