Surface Characterization of Thin Films & Coatings Symposium [2021]

Experience in Real Time the Characterization of Thin Films & Coatings

In this symposium, Bruker experts discuss and demonstrate leading-edge methods for the study of thin films and coatings, addressing common questions and challenges faced by researchers.

Webinar Summary

In support of innovation and continuous product and process improvement across industries, Bruker offers a variety of complementary techniques for the complete and effective characterization of thin films and coatings, including optical profilometry, atomic force microscopy (AFM), AFM-IR spectrometry, nanomechanical testing, and tribometry testing.

This on-demand workshop explores these solutions through a series of expert-led talks and live demonstrations. Each session aims to address common questions and challenges faced by researchers in this field and provide new insight into the characterization methods currently available.

Find out more about the technology featured in this webinar or our other solutions for advanced materials characterization.

ON-DEMAND RECORDING | 00:02:30

Good afternoon everybody and welcome to today's virtual workshop on surface characterization of thin films and coatings organized by Bruker Nano Surfaces and Metrology, GE division, in North America. My name is Mike Berg. I'll be your host for today and moderator of these sessions. I'm a Bruker nanoindentation product specialist based with our Minneapolis group. And I am excited to share with you our program.

Today's event is being recorded; everyone who registered will receive a follow-up email with access to the on-demand content, so it'll be easy for you to check back on anything you might have missed or to feel free to forward this to your colleagues, as well. We aim to have this as an interactive event. So you can see already all of our team of application experts joining from our Santa Barbara, Billerica, Massachusetts, and San Jose offices. And at any point during the sessions today, you can submit your questions here in the control panel. After each of the talks, we will have a Q&A session and you'll get a chance to ask our team specific questions. At the end, if there's time, we'll also address any further questions.

Today we're going to be featuring a number of technologies from the Bruker product portfolio, which spans a wide range of characterization tools and complementary techniques ranging from the optical profiler, the AFM, the nanoIR spectrometer, the nanoindentation and nanomechanical instruments, as well as the TriboLab tribometer. These techniques are going to be reflected in our talks, so we will have talks on:

- Optical profiler measurement of the roughness and waviness of thick films and coatings;

- The highest resolution AFM modes for the characterization of typography and physical properties of thin films and coatings;

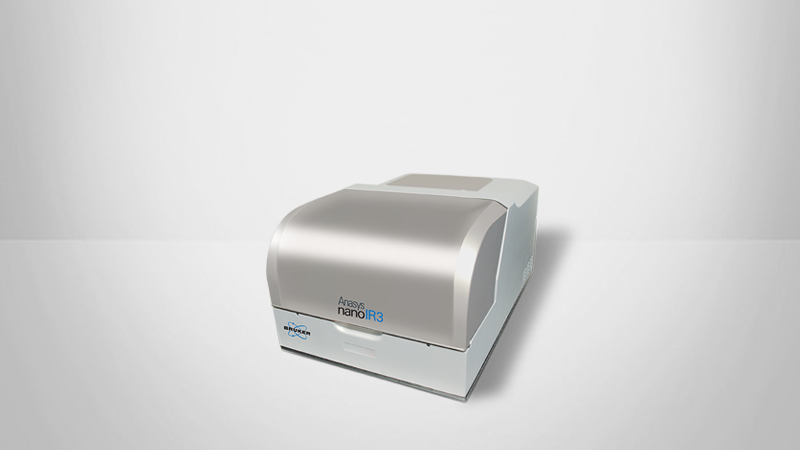

- For the nanoIR spectrometer, we'll be deconvoluting infrared spectra from stacked films using surface sensitive AFM-IR;

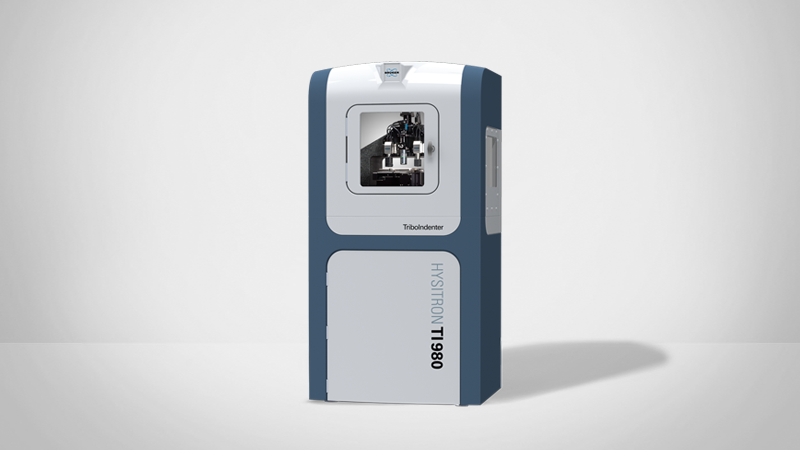

- For nanomechanical testing, we will be showing depth-sensing nanomechanical characterization of thin films and coatings; and

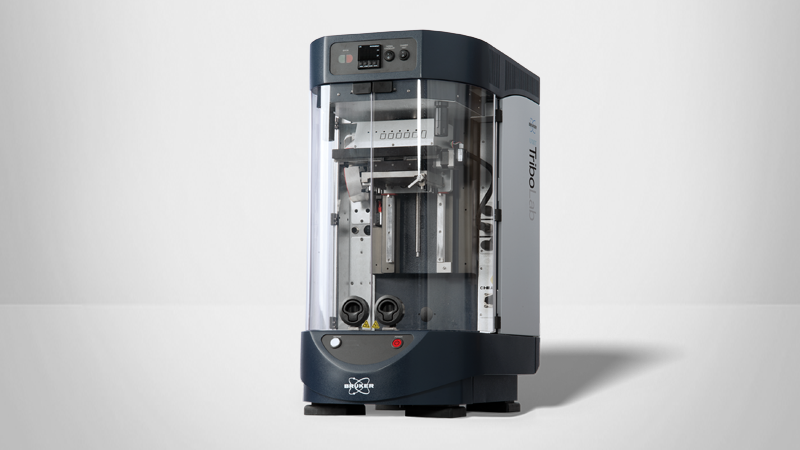

- For tribology, we'll be showing how to test coatings' wear and durability performance.

Each of the tests will also have a short demonstration of the equipment

Appreciate the Breadth of Bruker Thin Films & Coatings Characterization Techniques

Thin films and coatings are used for many purposes and in a variety of industries, serving vital functions in various consumer, manufacturing, and medical products. Examples from these market segments could range from micro-electronic components to screen displays, to food packaging or automotive products, and from eyeglass lenses to biomedical implants.

Regardless of the application, the performance and longevity of films and coatings depend on many factors including material, thickness, uniformity, surface roughness, stress, and adhesion to substrates. Product and process optimization rely on effectively characterizing these various properties; failure to do so can result in malfunctions and defects that can lead to substandard performance and lifespan.

This on-demand video explores Bruker's complementary techniques for the characterization of thin films and coatings through a series of expert-led talks and live demonstrations. Each session aims to address common questions and challenges faced by researchers in this field and provide new insight into the characterization methods currently available.

Watch this webinar to:

- Gain new insight into the advantages, applications, and practical limitations of five different methods of investigation.

- Understand how to correctly interpret data outputs showing the physical and mechanical properties, surface topography, and thickness of film and coating samples.

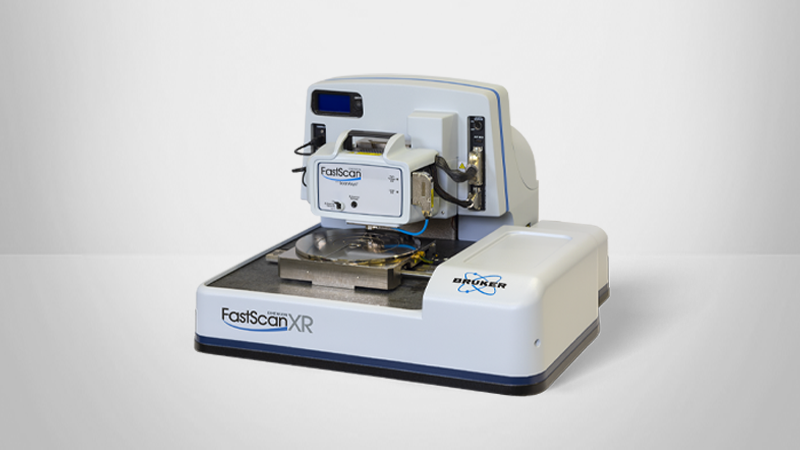

- See in real time how to characterize thin films and coatings using Bruker's ContourX-500, Dimension XR, Anasys nanoIR3, Hysitron TI 980 Nanoindenter, and UMT Tribolab.

- Hear experts answer audience questions about the best and most effective uses of these instruments and methods.

This webinar was presented on June 9, 2021.

Featured Products and Technology

Speakers

Ian Armstrong, Ph.D., Senior Manager AFM Probes, Bruker

Ian Armstrong has worked at Bruker for over 16 years in various roles from applications to product management. He is currently senior manager of Bruker's AFM probes business unit.

Senli Guo, Ph.D., Application Scientist, Bruker

Senli earned his Ph.D. in physical chemistry from Duke University (2009) and spent two years in the Center for Nanophase Materials Sciences (CNMS) at Oak Ridge National Lab as a postdoc before joining Bruker as an applications scientist in 2011. All of Senli’s research is about AFM-based methodology developments to address various nanoscience research, ranging from single-molecule interactions to lithium-ion battery electrode properties.

Cassandra Phillips, Ph.D.

Application Scientist, BrukerCassandra did her Ph.D. at the University of Toronto exploring the photophysics of boron nitride nanotubes using scattering scanning nearfield optical microscopy (s-SNOM) and computational models. She has been working at Bruker Nano Surfaces and Metrology since September 2019 as an Applications Scientist focusing on nanoscale IR spectro-microscopy and other correlated imaging techniques realized with atomic force microscopy.

Kora Farokhzadeh, Ph.D.

Application Scientist, Bruker

Kora is an application scientist in Bruker’s Tribology, Stylus, and Optical Metrology Group. She got her start in tribology as a graduate student in Materials Engineering, University of Windsor, Ontario, where she focused on dry sliding wear behavior of titanium alloys. She continued that subject into her doctoral studies to investigate surface engineering of titanium alloys for simultaneous wear and fatigue improvements. Later as a post-doc, her work experience can be summarized as surface engineering subjects, including design and fabrication of erosion- and corrosion-resistant cermet thermal spray coatings, wear-resistant polymer composite coatings, and protective coatings for automotive engine applications. Kora’s current role at Bruker lies at the forefront of innovative tribology testing techniques tailored for application, involving wear resistance and friction assessment, screening materials and surfaces by scratch testing and indentation hardness, and analysis of lubricants’ performance for a variety of automotive, biomedical and microelectronics applications. As part of her work, she is an affiliated graduate faculty at Southern Illinois University, collaborating on introducing a new benchtop technique to evaluate the behavior of friction brake materials.

Sandip Basu, Ph.D.

Application Scientist, BrukerSandip Basu is an applications scientist at Bruker Nano Surfaces and Metrology division, where he works extensively on nano-mechanical and nano-tribological behavior of coatings and thin films, along with surface texture analysis using white light interferometry and stylus profilometry. He has obtained his Ph.D. in Materials Science and Engineering from Drexel University and has been involved in the industry for more than 10 years developing and promoting applications for nano-scale surface metrology.