Why FT-NIR spectroscopy?

Understand the Basics

What is NIR?

Near InfraRed spectroscopy is an analysis method that uses the NIR

region of the electromagnetic spectrum (800 - 2,500 nm). It measures the absorption of light from the sample in the NIR region at different wavelengths. The recorded NIR spectrum consists of overtones and combination vibrations of molecules that contain CH, NH or OH groups. This makes NIR spectroscopy the first choice for the analysis of organic materials in the chemical and pharmaceutical industry, as well as in the food, feed and agricultural industries.

How do I evaluate an NIR spectrum?

The NIR bands usually overlap leading to a spectrum with broad peaks, which makes the NIR spectrum of a sample more difficult to interpret as compared to its mid-infrared spectrum. However, within these NIR spectra which are comparable poor in features, there is considerable information about the molecular and physical structure of the sample, and this information can be accessed by modern multivariate data processing and evaluation methods to analyze the sample composition.

Benefits of FT-NIR

Most spectroscopic techniques are fast and accurate compared to wet chemistry, but FT-NIR spectroscopy has some other advantages which makes is very useful for routine analysis in QC labs and in process control. FT-NIR can help you to streamline the analysis routines in the lab and online. It is often able to analyze many different parameters with just one measurement and without any sample preparation saving labour and money.

No Sample Preparation

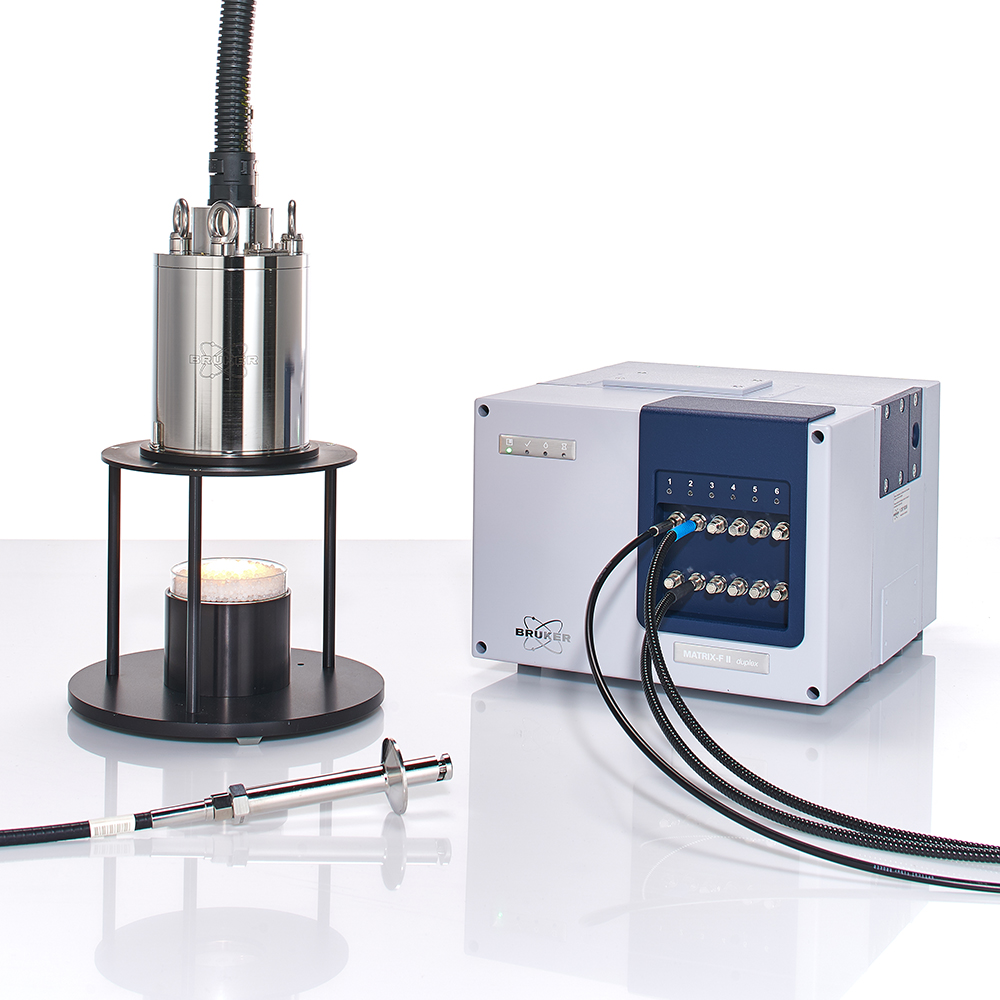

For an NIR measurement in the lab, the sample is simply filled into a glass vial or beaker, because glass is transparent in the NIR spectral region. This also allows the use of fiber optic probes in the lab as well as in process environments.

Ideal for heterogeneous material

The NIR light not only analyzes the surface, but penetrates deeper into the material. This makes it ideal for measuring heterogeneous samples. In addition, FT systems (in contrast to dispersive spectrometers) offer the possibility of continuously rotating the sample during the analysis in order to record a larger sample volume compared to a single, static measurement. This makes the result more representative and leads to greater accuracy.

No Waste, No Chemicals

In contrast to time-consuming standard analyses, the NIR method produces no wastes, causes no pollution, and requires no chemical reagents or gases, making it very cost-effective.

Large sample throughput

An FT-NIR analysis is fast (measurement times 10 to 60 seconds) and without sample preparation a substantial amount of time is gained compared to wet chemical analysis. NIR is providing a high sample throughput in a lab and real time analysis in process monitoring.

Selecting the best measurement mode

There are three important types of optical measuring modes: transmission, diffuse reflection, and transflection. Based on these modes a large selection of dedicated sampling accessories can be used depending on the optical properties of the sample.

Transmission

When measuring in transmission, the light is directed at a sample with a focused or parallel beam. Some light is absorbed but the remaining part is transmitted to the detector. This type of measurement is not only used for clear liquids (direct transmission), even diffusely reflecting or slightly scattering samples like grain and pasty samples can be analyzed in this way (diffuse transmission).

Transflection

Transflection is an extension of the transmission technique. When a mirror is placed behind the sample, the light transmitted through the sample is reflected back through the sample and into the diffuse reflectance probe or integrating sphere. Transflection thus measures a combination of transmission and reflection. This technique is useful for emulsions, gels, and turbid liquids. Transflection probes are available as well to analyze e.g. turbid liquids like milk or in a fermentation process in-line.

Diffuse Reflection

When light is reflected from solid surfaces or particles in powders, pellets or granulates, it is called diffuse reflection. In an integrating sphere light is directed in a broad nearly parallel beam onto a sample. The diffusely reflected light is well distributed in the sphere by multiple diffuse reflections at the gold-plated inner surface, "homogenizing" the light. Therefore an integrating sphere is well suited for inhomogeneous samples as well as for fine powders. Depending on the sample, light may penetrate beyond the surface a significant distance, e.g. for powders its approx. 2 to 4mm depending on particle size, wavelength and density, thus enabling the quantification of components within the sample.

Why FT-NIR Spectroscopy?

Learn more about the benefits of FT-NIR spectroscopy and how it can help you in your daily QC work.