FilmTek 2000 PAR-SE

FilmTek 2000 PAR-SE

Combining patented Multi-Angle Differential Polarimetry (MADP) and Differential Power Spectral Density (DPSD) technology, the FilmTek™ 2000 PAR-SE utilizes multi-angle and multi-modal data collection to independently measure film thickness and index of refraction. By independently measuring index and thickness, the FilmTek 2000 PAR-SE is far more sensitive to changes in films, particularly films within multi-layer stacks, than existing metrology tools that rely on conventional ellipsometry or reflectometry techniques. The FilmTek 2000 PAR-SE is a fully-integrated package, paired with advanced material modeling software to make even the most rigorous measurement of patterned wafers reliable and intuitive.

Measurement Capabilities

Enables simultaneous determination of:

- Multiple layer thicknesses

- Indices of refraction [ n(λ) ]

- Extinction (absorption) coefficients [ k(λ) ]

- Energy band gap [ Eg ]

- Composition (e.g., %Ge in SiGex, % Ga in GaxIn1-xAs, %Al in AlxGa1-xAs, etc.)

- Surface roughness

- Constituent, void fraction

- Crystallinity/Amorphization (e.g., of Poly-Si or GeSbTe films)

- Film gradient

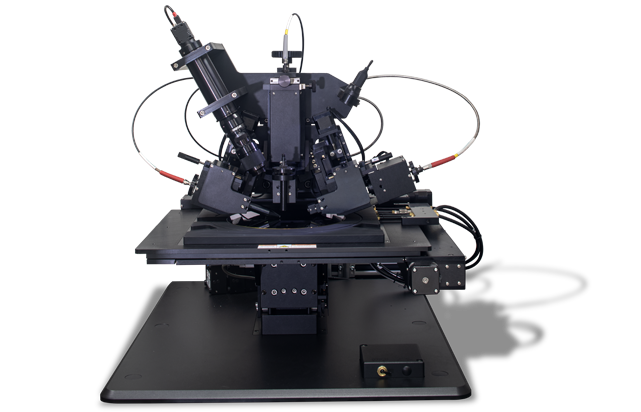

System Components

Standard:

- Spectroscopic ellipsometry with rotating compensator design (295 nm - 1700 nm)

- Multi-angle, polarized spectroscopic reflection (190 nm - 1700 nm)

- Measures film thickness and index of refraction independently

- Multi-Angle Differential Polarimetry (MADP) technology with SCI’s patented Differential Power Spectral Density (DPSD) technology

- Ideal for measuring ultra-thin films (0.03 Å repeatability on native oxide)

- Camera for imaging measurement location

- Pattern recognition

- 50 micron spot size

- Advanced material modeling software

- Bruker's generalized material model with advanced global optimization algorithms

Optional:

- Generalized ellipsometry (4×4 matrix generalization method) for anisotropy measurements (nx, ny, nz)

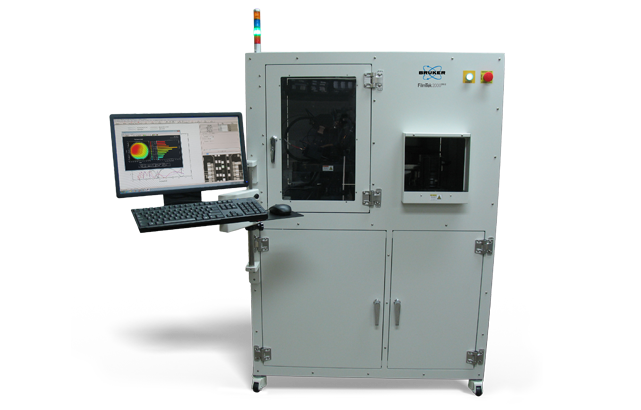

- Cassette to cassette wafer handling

- FOUP and SMIF compatible

- Pattern recognition (Cognex)

- SECS/GEM

Typical Application Areas

Virtually all translucent films ranging in thickness from less than 1 Å to approximately 150 µm can be measured with high precision. Typical application areas include:

Multi-layer Thin Films

Collect accurate, precise production measurements of thin films and multi-layers on patterned device wafers for front and back-end manufacturing.

Filmtek advanced multi-angle and multi-modal technology enables in-line composition control (e.g., %Ge in SiGex) for thin films, Oxide / Nitride / Cu, CMP process monitoring, and measurement of thin metal oxide thickness (SnO, CuO, InO) with sub-Angstrom repeatability to prevent non-wet open failures in bonding processes.

MEMS

Perform fully-automated film thickness and refractive index measurements of oxide, nitride, oxide/nitride, ONO, amorphous carbon, resist, and oxide/polysilicon/oxide films on patterned device wafers.

Fully-automated FilmTek ellipsometry and reflectometry tools feature cassette-to-cassette wafer handling, 50µm spot size, pattern recognition, and SECS/GEM with a best-in-class combination of performance and price.

New Materials

Characterize new materials with a wide range of rapid, accurate, and reliable R&D measurement capabilities.

FilmTek benchtop tools with automated wafer mapping enable measurements of multiple layer thicknesses, indices of refraction [n(λ)], extinction (absorption) coefficients [k(λ)], energy band gap [Eg], composition (e.g., %Ge in SiGex, % Ga in GaxIn1-xAs, %Al in AlxGa1-xAs, etc.), surface roughness, constituent / void fraction, crystallinity / amorphization (e.g., degree of crystallinity of Poly-Si or GeSbTe films), and film gradient.

Unknown/Complex Materials

Independently and unambiguously determine thickness (t), refractive index (n), and extinction coefficient (k) for unknown materials.

FilmTek combined multiple-angle reflectometry and rotating compensator design ellipsometry systems deliver unprecedented performance with high-throughput automated mapping of patterned and un-patterned samples, 0.03 Angström repeatability for thin films, an extended thickness range from bare substrate to 50µm, and sub-Angström accuracy for complex, multi-layer thin film structures.

Technical Specifications

| Film Thickness Range | 0 Å to 150 µm |

|---|---|

| Film Thickness Accuracy | ±1.0 Å for NIST traceable standard oxide 100 Å to 1 µm |

| Spectral Range | 190 nm - 1700 nm (220 nm - 1000 nm is standard) |

| Measurement Spot Size | 25 µm - 300 µm (normal incidence); 2 mm (70°) |

| Sample Size | 2 mm - 300 mm (150 mm standard) |

| Spectral Resolution | 0.3 nm - 2nm |

| Light Source | Regulated deuterium-halogen lamp (2,000 hrs lifetime) |

| Detector Type | 2048 pixel Sony linear CCD array / 512 pixel cooled Hamamatsu InGaAs CCD array (NIR) |

| Automated Stage with Auto Focus | 300 mm (200 mm is standard) |

| Computer | Multi-core processor with Windows™ 10 Operating System |

| Measurement Time | <1 sec per site (e.g., oxide film) |

Performance Specifications

| Film(s) | Thickness | Measured Parameters | Precision (1σ) |

|---|---|---|---|

| Oxide / Si | 0 - 1000 Å | t | 0.03 Å |

| 1000 - 500,000 Å | t | 0.005% | |

| 1000 Å | t , n | 0.2 Å / 0.0001 | |

| 15,000 Å | t , n | 0.5 Å / 0.0001 | |

| 150.000 Å | t , n | 1.5 Å / 0.00001 | |

| Nitride / Si | 200 - 10,000 Å | t | 0.02% |

| 500 - 10,000 Å | t , n | 0.05% / 0.0005 | |

| Photoresist / Si | 200 - 10,000 Å | t | 0.02% |

| 500 - 10,000 Å | t , n | 0.05% / 0.0002 | |

| Polysilicon / Oxide / Si | 200 - 10,000 Å | t Poly , t Oxide | 0.2 Å / 0.1 Å |

| 500 - 10,000 Å | t Poly , t Oxide | 0.2 Å / 0.0005 |

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.