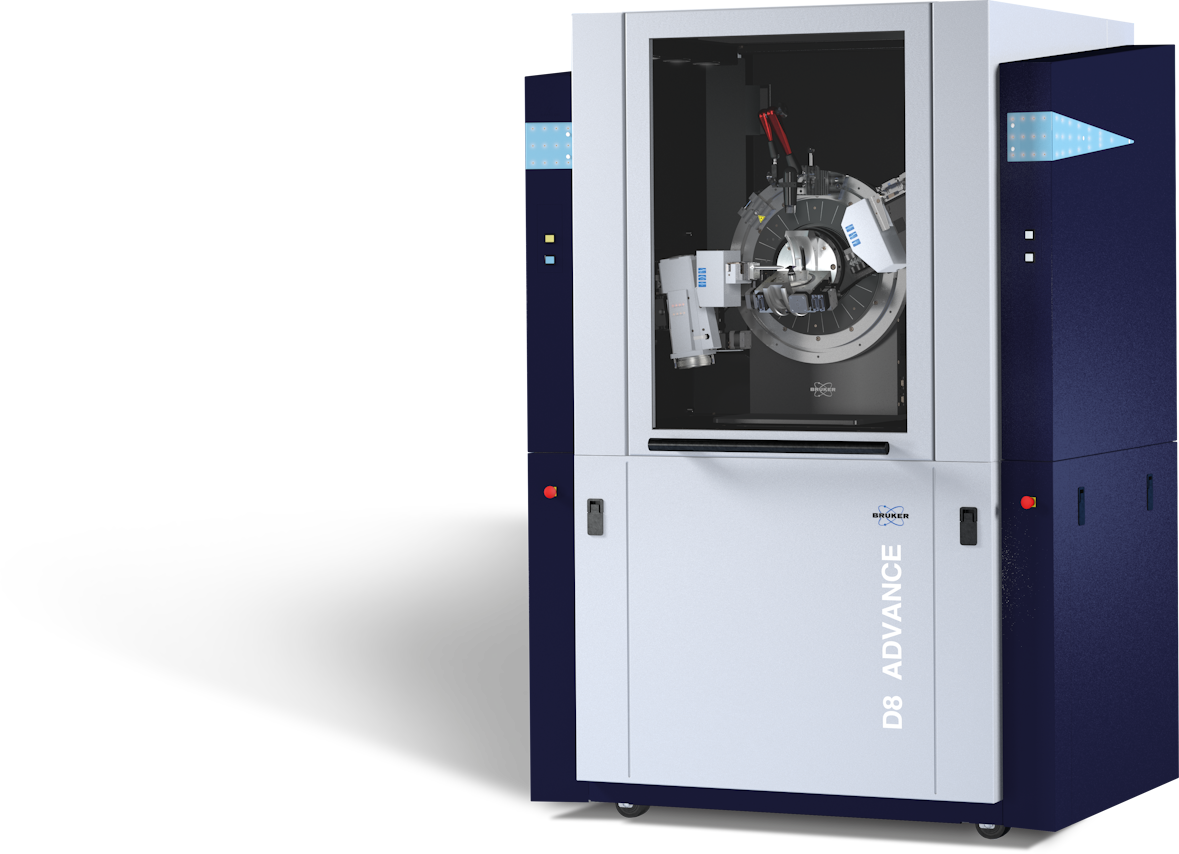

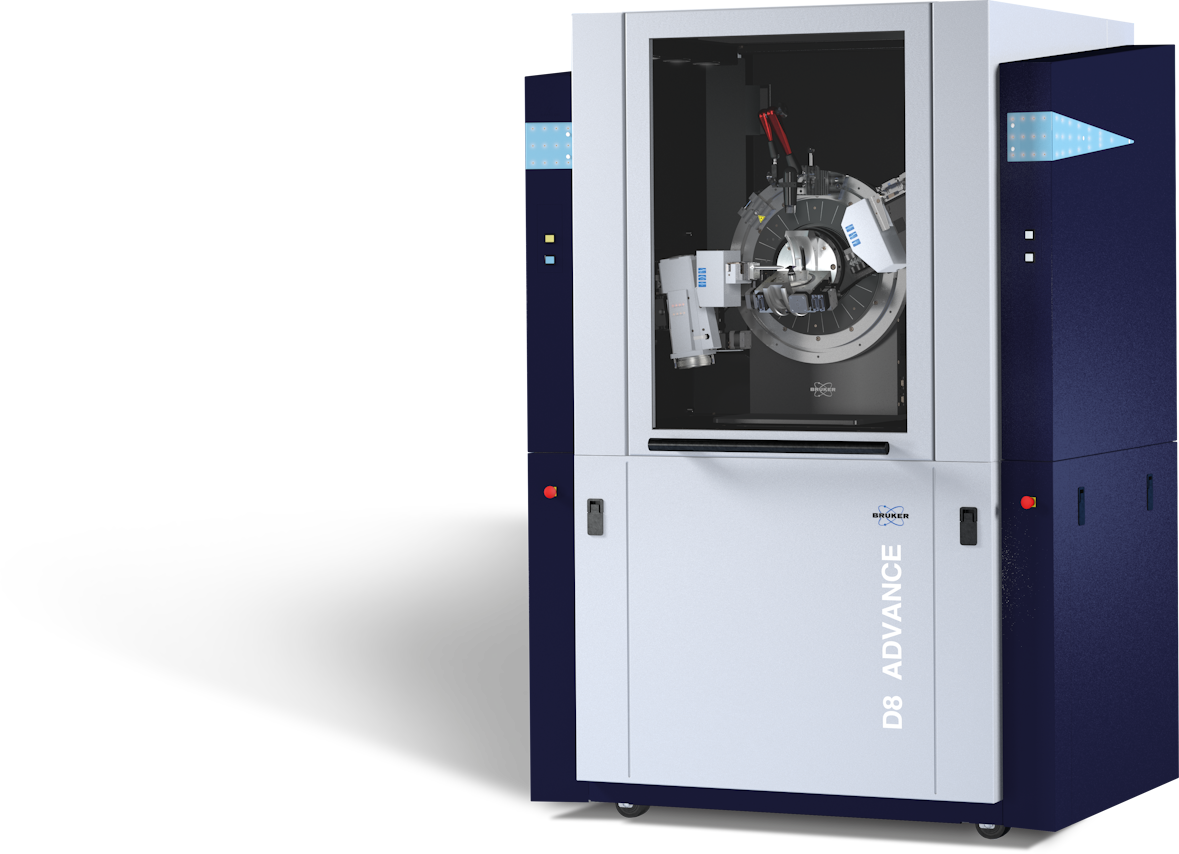

D8 ADVANCE Plus

The D8 ADVANCE Plus: Multipurpose Materials Research

D8 ADVANCE Plus - maximum flexibility meets unparalleled ease-of-use

The D8 ADVANCE Plus is a D8 ADVANCE variant representing the ultimate X-ray platform for multi-purpose, multi-user laboratories. The system perfectly matches the needs of all sample types including powders, bulk materials, fibers, sheets and thin-films (amorphous, polycrystalline and epitaxial):

- traditional X-ray powder diffraction (XRD)

- Pair Distribution Function (PDF)analysis

- Small and Wide Angle X-ray Scattering (SAXS, WAXS)

- XRR (reflectometry) and HRXRD (rocking curves, reciprocal space mapping)

at ambient and non-ambient conditions.

The real beauty of the system is its ability to switch between up to 6 different beam geometries, from focusing Bragg-Brentano geometry for powders to high-resolution parallel-beam Kα1 geometry for epitaxial thin films and everything in-between. Fully software controlled, at the push of a button.

Whatever the sample type and application is, and no matter if you are a novice or an expert user: The D8 ADVANCE Plus sets a new benchmark in data quality thanks to its unparalleled flexibility and easy-of-use.

Market Gallery

Key Features

TRIO optics

The patented TRIO optics simplify the usage of the D8 ADVANCE, allowing the largest variety of applications and sample types. With user convenience in mind, the system features automatic, motorized switching between up to 6 different beam geometries. Without manual user intervention, the system is capable of switching between three beampaths:

- Focusing Bragg-Brentano for powders

- High intensity parallel beam Kα1,2 for capillary, GID and XRR

- High-resolution parallel-beam Kα1 geometry for epitaxial thin films

It is perfectly suited for all sample types including powder, bulk, fiber, sheet and thin-film (amorphous, polycrystalline and epitaxial) under ambient or non-ambient conditions.

Materials Research Stages

The Compact UMC and Compact Cradle Plus extend the sample handling capability of the D8 ADVANCE Plus allowing complex precision motion of the sample. The Comact UMC stage features motorized motion of 25 mm in X, 70 mm in Y and 52 mm in Z with 2 kg sample capacity for analysis of large bulk samples or multiple smaller samples. The Compact Cradle Plus includes unlimited Phi rotation and Psi tilt from -5° to 95° for stress, texture and epitaxial thin film analysis. In addition, the Compact Cradle Plus features a vacuum utility feedthrough allowing samples to be held in place with either a small thin film sample holder or large manual XY table. Both stages accommodate dome temperature stages for non-ambient analysis. They also utilize the DIFFRAC.DAVINCI stage bayonet mounting system for easy exchange of the sample stage.

EIGER2 R detectors

Multimode functionality (0D-1D-2D, snapshot and scanning modes) allows the EIGER2 R detectors to cover a wide range of measurement methods ranging from powder to materials research applications. Not the typical jack of all trades, the EIGER2 is a master of all applications. With a dynamic range that allows absorber free measurements, large 1D size for ultra fast powder measurements and rapid reciprocal space maps and over 500k pixels for large two dimensional coverage, the EIGER2 sets a new standard for multimode detectors. The EIGER2 combines beamline detector technology from DECTRIS Ltd. with software and hardware integration from BRUKER into a seamless easy to use solution.

Application Gallery

EIGER2 R detector

One Diffractometer - All Applications

Powder Diffraction

X-ray powder diffraction (XRPD) techniques are among the most important tools for materials characterization. Much of the information embedded in a powder pattern is derived directly from the atomic arrangement of the phases present. The D8 ADVANCE and the DIFFRAC.SUITE software allow support simple execution of common XRPD methods:

- Identification of both crystalline and amorphous phases and determination of specimen purity

- Quantitative analysis of both crystalline and amorphous phases in multi-phase mixtures

- Microstructure analysis (crystallite size, microstrain, disorder…)

- Bulk residual stress resulting from thermal treatment or machining in manufactured components

- Texture (preferred orientation) analysis

- Indexing, ab-initio crystal structure determination and crystal structure refinement

Pair Distribution Function Analysis

Pair distribution function (PDF) analysis is an analytical technique that provides structural information from disordered materials based on Bragg as well as diffuse scattering ("Total Scattering"). While Bragg peaks provide information about the average crystal structure of a material (i.e. long range order), diffuse scattering allows characterization of its local structure (i.e. short range order).

The D8 ADVANCE and TOPAS software represent the highest performing PDF analysis solutions on the market in terms of analysis speed, data quality and results for analysis of amorphous, poorly crystalline, nano-crystalline or nano-structured materials:

- Phase identification

- Structure determination and refinement

- Nano particle size and shape

Residual Stress and Texture Analysis

Residual stress and texture measurements are routinely collected on industrial metal samples where materials are pushed to their limits. By relieving tensile stress or inducing compressive stress in the surface of a sample, its functional life can be greatly extended. This can be done through thermal treatments or physical processes such as shot peening. The orientation of crystallites which make up a bulk sample dictate the way in which cracks will propagate. By forming specific textures in a material, its properties can be dramatically increased. Both of these techniques are also important in optimizing cutting edge fabrication method such as additive manufacturing.

Thin Films and Coatings

Analysis of thin films and coatings is based on the same principles of XRPD, but with further beam conditioning and angular control. Typical examples include, but are not limited to, phase identification, crystalline quality, residual stress, texture analysis, thickness determination and composition vs strain analysis. Analysis of thin films and coatings is focusing on properties of layered materials with nm to µm thickness, ranging from amorphous and poly-crystalline coatings to epitaxially grown films. The D8 ADVANCE and the DIFFRAC.SUITE software enable high quality analyses of thin films including:

- Grazing Incidence Diffraction

- X-Ray Reflectometry

- High Resolution X-ray Diffraction

- Reciprocal Space Mapping

(U)SAXS, (U)WAXS, and GISAXS

Analysis of X-ray scattering data acquired at wide, small, and ultra-small angles enables the determination of nano-scale structures, shapes, and distributions. Applications include the characterization of nanoparticle systems, colloids, surfactants, protein solutions, polymers, liquid crystals, nanocomposites, and porous materials.

Small Angle X-ray Scattering (SAXS) utilizes data collected between 0.1 and 5° 2θ, providing information on structural features in the order up to about 80 nm, and is complemented by Wide Angle X-ray Scattering (WAXS), which provides information on the periodic arrangement of structures. To investigate larger structures up to the micron range, the high-resolution beam path provided by the TRIO optics and USAXS module adds Ultra Small Angle X-ray Scattering (USAXS) capabilities to the D8 ADVANCE.

For studying nanoscale structures on thin films, the GIWAXS stage has a built-in knife edge collimator and beam stop for superb background suppression, crucial for observing weak signals typical for GISAXS and GIWAXS applications. The stage design allows for minimum sample-to-detector distance to maximize angular coverage. Alternatively for GISAXS measurements, the EIGER2 R can be placed far away from the sample to increase resolution.

Application Gallery

Pair Distribution Function Generation and Refinement

D8 ADVANCE Plus Specifications

Feature | Specification | Benefit |

TRIO optics | Software push-button switch between: Motorized Divergence Slit (Bragg-Brentano) High Intensity Ka1,2 Parallel Beam High Resolution Ka1 Parallel Beam Patents: US10429326, US6665372, US7983389 | Fully automatic, motorized switching between up to 6 different beam geometries without any manual user intervention Perfectly suited for all sample types including powders, bulk materials, fibers, sheets and thin-films (amorphous, polycrystalline and epitaxial) |

LYNXEYE XE-T | Energy Resolution: < 380 eV @ 8 KeV Detection Modes: 0D,1D, 2D Wavelengths: Cr, Co, Cu, Mo and Ag Patents: EP1647840, EP1510811, US20200033275 | No need for Kß filters and secondary monochromators 100% filtering of Fe-fluorescense with Cu radiation Up to 450 times faster than conventional detector systems BRAGG2D: Collect 2D data with a divergent primary line beam Unique detector warranty: No defective channels at delivery time |

EIGER2 R | The latest generation multi-mode (0D/1D/2D) detector based on the Hybrid Photon Counting technology, developed by Dectris Ltd. | Seamless integration of 0D, 1D and 2D detection in step, continuous and advanced scanning modes Ergonomic, alignment-free detector rotation to optimize γ or 2Θ angular coverage Panoramic, tool-free diffracted beam optics using the complete detector field of view Continuously variable detector positioning to balance angular coverage and resolution |

TWIST.TUBE | Easy, fast, and alignment-free switch between line and point focus applications | No disconnecting of electric cables or water hoses or unmounting of tubes DAVINCI.DESIGN: Fully automatic detection and configuration of the focus orientation |

Compact UMC Stage | Motorized X: 25 mm Motorized Y: 70 mm Motorized Z: 52 mm Capacity: 2 kg | Precise positioning of the region of interest of a large sample in the beam Mounting multiple samples for automatic measurements |

Compact Cradle Plus | Motorized Phi: Unlimited Motorized Psi: -5° to 95° | Vacuum utility feedthrough for worry-free sample mounting Full 4 axis diffraction allows texture, residual stress and thin film measurements |

D8 Goniometer | Two-circle goniometer with independent stepper motors and optical encoders | Unparalleled accuracy and precision as manifasted by Bruker's unique alignment guarantee Absolutely maintenance free drive mechanism / gearings with lifetime lubrication |

Non-ambient | Temperature: Ranging from ~85K up to ~2500K Pressure: 10-⁴ mbar up to 10 bar Humidity: 5% to 95% RH | Investigations under ambient and non-ambient conditions Easily exchanged stages with DIFFRAC.DAVINCI |

XRD Components

Bruker XRD solutions consist of high performance components configured to meet the analytical requirements. The modular design is the key to configure the best instrumentation.

All categories of components are part of Bruker’s key competence, developed and manufactured by Bruker AXS, or in close cooperation with third party vendors.

Bruker XRD components are available for upgrading the installed X-ray systems for improving their performance.

PLAN.MEASURE.ANALYZE with DIFFRAC.SUITE

DIFFRAC.SUITE™ offers a wide range of software modules for easy X-ray powder diffraction data acquisition and evaluation. Based on Microsoft's .NET technology, DIFFRAC.SUITE offers all the advantages of modern software technology for stability, maximum ease of use and networking.

The fully customizable user-interface is characterized by a plug-in framework, providing a common look, feel and operation. All measurement and evaluation software modules can be operated as individual applications or integrated together in DIFFRAC.SUITE's plug-in framework. Unlimited networking allows access and control of any number of D6 PHASER, D8 ADVANCE, D8 DISCOVER and D8 ENDEAVOR diffractometers within a customer's network.

Measurement Software:

WIZARD – Method planning

COMMANDER – Method execution and direct measurements

TOOLS – Service Interface

Powder Diffraction Software:

DQUANT – Quantitative phase analysis

EVA – Phase identification and quantitative phase analysis

TOPAS – Profile analysis, quantitative analysis, structure analysis

Materials Research Software:

SAXS – Small Angle X-ray Scattering software

TEXTURE – All-round Texture analysis meets ease-of-use

LEPTOS – Thin film analysis/Residual stress investigation

D8 ADVANCE Plus Resources

Brochures & Flyers

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)