An Introductory Course for Nanoindentation of Hard Coatings

Hear thorough explanations of nanomechanical metrology for hard coatings

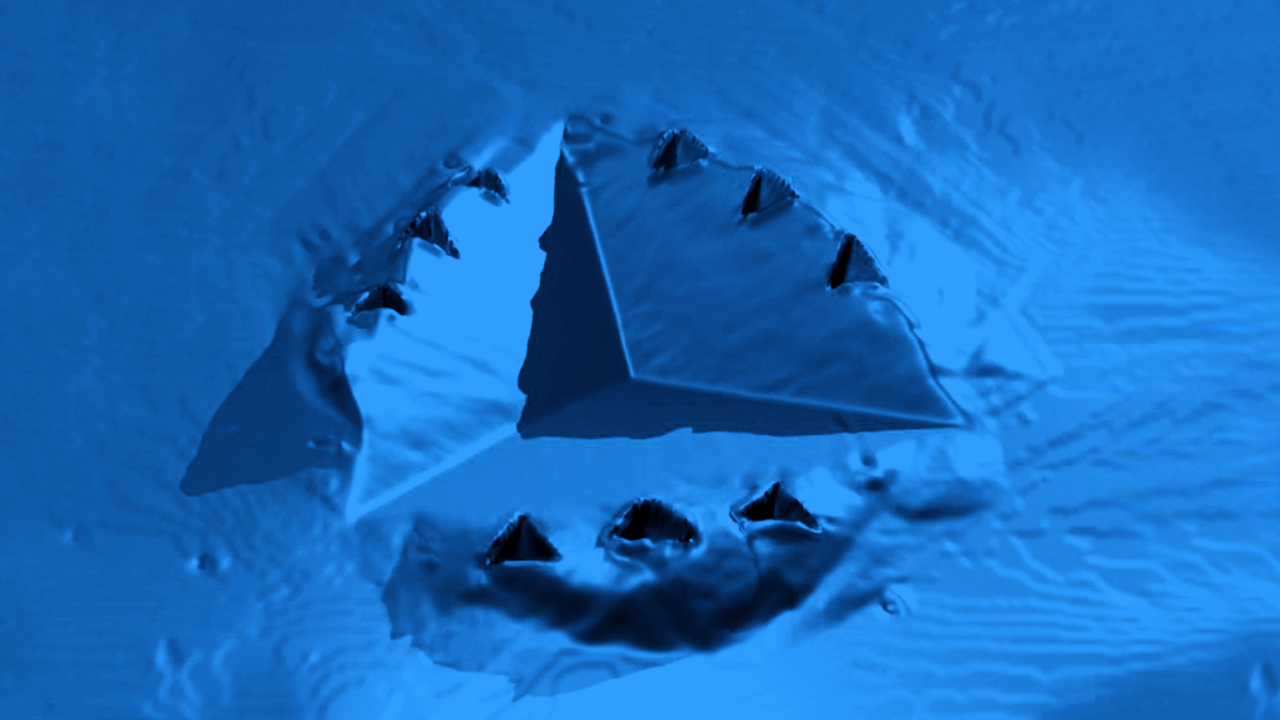

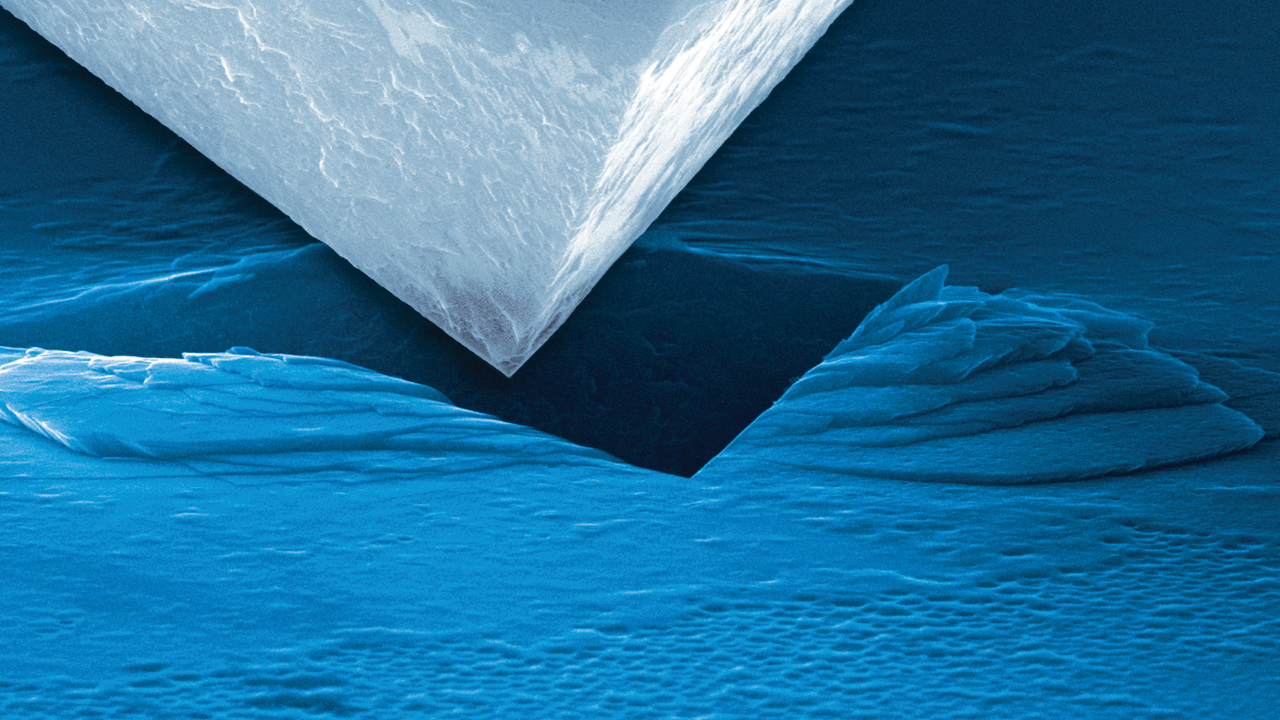

Nanoindentation is a common technique for measuring mechanical properties at small scales, including on films and coatings. In this webinar, the technique for measuring tooling coatings is detailed thoroughly from beginning to end for introductory users, with PVD and CVD coatings as examples.

Viewers will learn how to:

- Perform hardness and modulus measurements on a simple substrate

- Progress to real samples that deviate from ideal

- Identify and mitigate effects from the substrate under a film or coating

Webinar Summary

Vickers microhardness testing of tool coatings has limitations for thin films. Nanoindentation is a technique that can overcome these limitations.

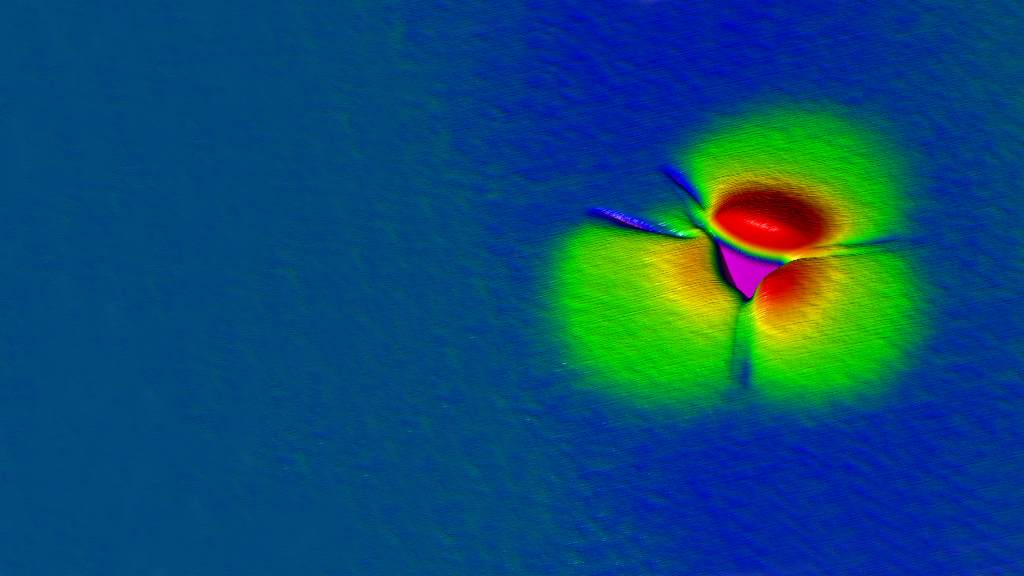

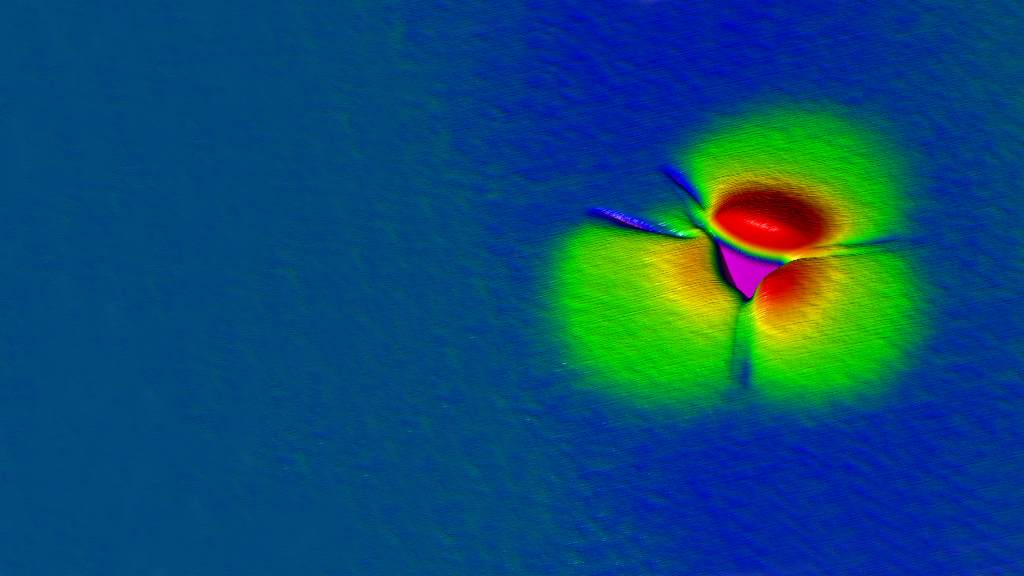

Dr. Jungkyu Lee presents an introductory webinar on nanoindentation of hard coatings. He provides a primer on nanoindentation, explaining how the technique works and how hardness and modulus are calculated from the load-displacement curves.

Dr. Lee shows examples of using nanoindentation to characterize six commercially available tool coatings, both at room temperature and at high temperatures. He discusses the challenges of measuring rough coatings and outlines some general guidelines for nanoindentation of these types of samples.

Find out more about the technology featured in this webinar or our other solutions for Nano-Indentation of Hard Coatings:

Featured Products and Technology

Speaker

Jungkyu Lee, Ph.D.

Applications Specialist, Bruker