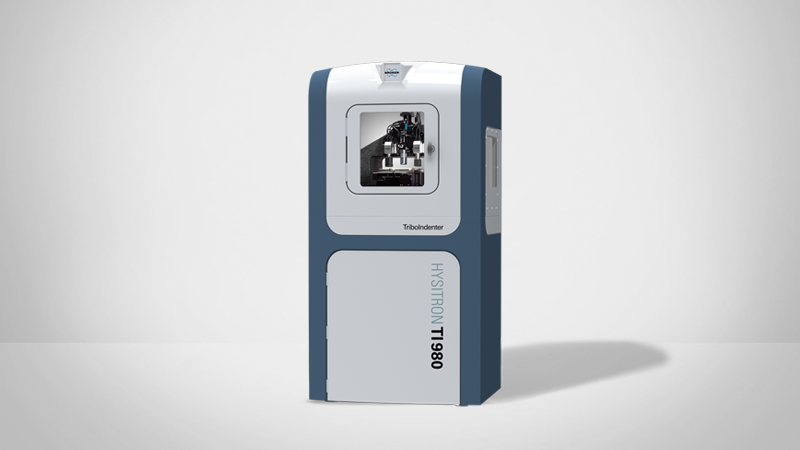

Temperature Control Stages

Explore nanomechanical and nanotribological properties as a function of temperature

Bruker offers a variety of temperature control stages to compliment the TI Series of nanomechanical test instruments. Using a temperature control stage allows the user tocharacterize materials at non-ambient temperatures. Non-ambient testing is important when working with metals, biomaterials, polymers, semiconductors, and many other materials that are intended for real-world applications at elevated or reduced temperatures.

37°C Temperature Control Stage

The 37°C Temperature Control Stage was developed by Hysitron for testing of biological and biomedical materials. The 37°C Temperature Control Stage operates from room temperature up to 37°C. The simplified operation of the 37°C Temperature Control Stage does not require any gain settings or additional software and is ready to use out of the box.

100/200°C Temperature Control Stage

Hysitron 100/200°C Temperature Control Stage is capable of operating from -10°C up to 100°C or 200°C, depending on model. The 100°C Temperature Control Stage utilizes a Peltier device for heating and cooling. The 200°C temperature stage uses a Peltier device for cooling and a resistive heating element to achieve higher temperatures. Both stages are constructed out of thermally stable ceramic for temperature stability and are water cooled to minimize heat transfer to the nanomechanical test instrument.

For temperature testing up to 800°C, see our xSol High Temperature Stage.