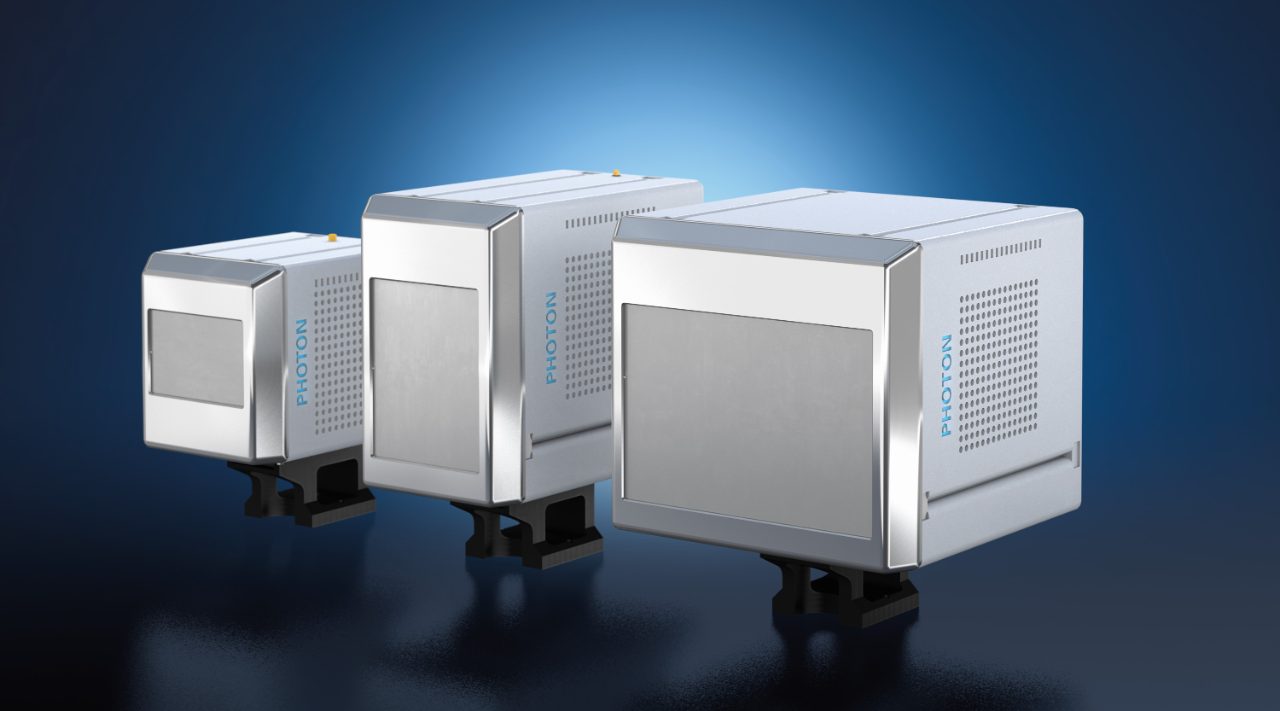

Multilayer Mirror Technology

Graded multilayer mirrors for X-ray diffraction were first developed under H. Goebel by Siemens branches in Munich and Karlsruhe (now Bruker AXS) in the mid 90’s. Since then, synthetic multilayer optics have revolutionized the field of monochromators as for the first time highly efficient beam-shaping devices became available which can shape the X-ray beam in one or two dimensions, while forming a focused or parallel beam. Their high reflectivity, broad rocking curve, excellent spectral purity and tunable beam parameters make graded multilayer mirrors the perfect choice for microfocus X-ray sources, preserving the brilliance of the source.

Our graded multilayer mirrors consist of alternating stacks of a reflector layer, such as W or Ni, and a space layer, such as C or B4C. This allows the production of carefully designed multilayer structures with a lateral gradient of the layer thickness along the optics. To fulfill Bragg‘s law for the varying incident angles - and to guarantee the highest quality - the agreement between theoretical values and the achieved values of the layer thickness along the optics must be within better than 1%.

As a spin-off of the thin-film research department at the former GKSS Research Center Geesthacht, INCOATEC has gathered experience in the deposition of multilayer structures for more than 30 years. Since day one our mirrors achieve highest quality standards.

Today, INCOATEC´s graded multilayer mirrors are used in the majority of Bruker’s X-ray analytical solutions.

Typical applications range from analyzer crystals in X-ray fluorescence (XRF) to monochromators for one- and two-dimensional beam shaping in X-ray diffraction (XRD), small angle scattering (SAXS) and single crystal diffraction (SC-XRD). INCOATEC is also deeply involved in the development of new highly reflective mirrors for synchrotron applications in the soft X-ray regime, where ultra-precise single- and multi-layer coatings are the key to success.