Automotive and Aerospace

Driven by Quality, Powered by Reliability

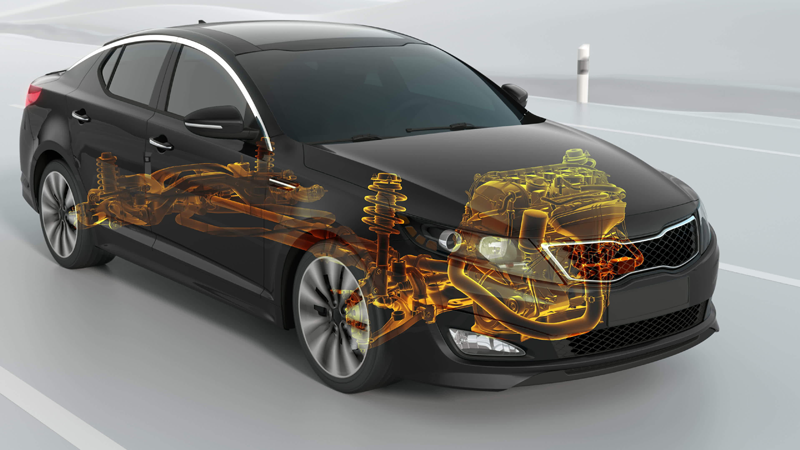

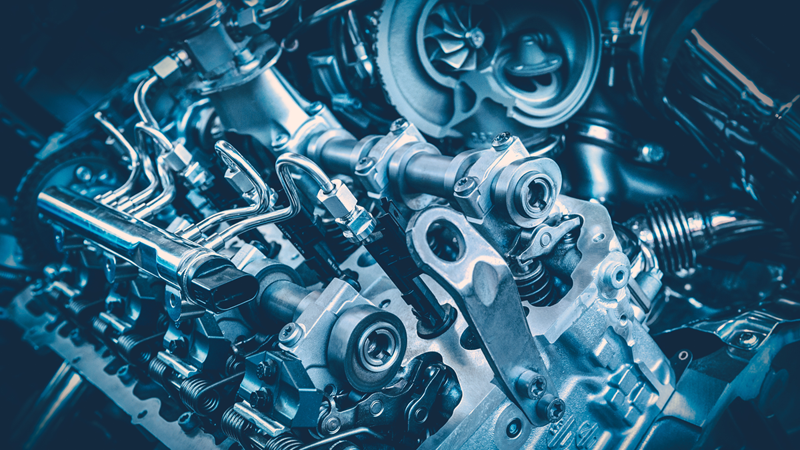

Automotive and aerospace components have to work reliably under extreme conditions and constant strain. It is important to both test products under real-world conditions, and to perform precise measurements of materials and components to help predict and prevent product failures. Bruker’s mechanical testers and nanoindentation solutions are uniquely capable of replicating the exact temperature ranges, material interactions, and operating conditions of an extremely wide variety of automotive and aerospace applications.

Bruker's wide portfolio also includes a unique range of analytical tools for materials characterization on electron microscopes to analyze chemical and crystallographic properties in the sub-micron range.

Our Micro-XRF (X-Ray Fluorescence) spectrometers offer spatially resolved, non-destructive material analysis (mapping) or layer thickness analysis down to trace levels without any specimen preparation.

In addition, Bruker’s industry-leading 3D optical microscopes provide the most accurate and application-flexible surface measurements to enable faster ramp-up times, enhanced product quality, and increased productivity. Whether measuring on production floors or in QA/QC labs, Bruker delivers a testing or metrology solution for your specific measurement needs.