Lubricants Testing

Evaluating Lubricity and Tribological Properties of Lubricants and Additives

Lubricants and additives play a significant role in many industries. Their performance is critical to the speed, reliability, and life of nearly every type of machinery. To design lubricant formulations that deliver the best results, lubricity and tribology tests must replicate extreme pressures and real-world conditions.

Using the right lubricant formula can reduce the friction and wear between surfaces. Many industries have defined standards and test methods to characterize lubricity quality. For example, brakes, clutches, and engines are all tested for properties in accordance with ASTM, DIN, JIS, ISO and other standards.

Why invest in an in-house solution?

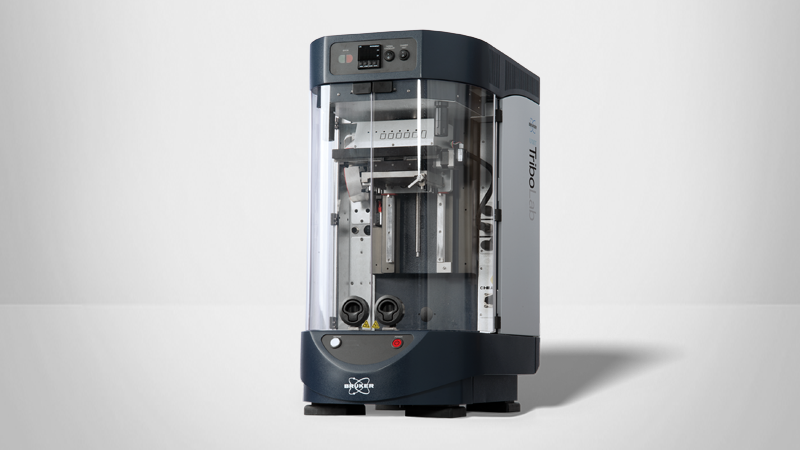

Many manufacturers rely on expensive, and time-intensive contract testing services to evaluate and research new lubricants. As an alternative, Bruker's UMT TriboLab benchtop tester performs multiple tests for perfecting chemistry and proving the performance of formulations. A wide range of drives and sensors enables engineers to perform both standard and customized tests. Our solution provides a fast, affordable path to perfecting chemistry and proving out formulations.

- Test samples on a small scale and correlate to large, expensive test rigs

- Innovate faster with in-process evaluations of formulas

- Easily change testing conditions as you develop formations

- Perform Quality Assurance, Quality Control, and R&D in one lab on one tool

What kinds of lubricants and additives do we test?

- Diesel Oil

- Coolants

- Synthetics

- Lubricating Oils

- Lubricating Greases

- Automotive Lubricants

- Dry Lubricants

- Industrial Lubricants

- Base oils

- Green Lubricants

- Gear Oils

- Lubricating Pastes

- Waxes

- Turbine Oils

- Hydraulic Oils

- Compressor Oils

Additive and Lubricant Test Solutions from Bruker

- Lubricity - High Frequency Reciprocating Rig (HFRR)

- Line-contact or conformal contact - Block on ring

- Small area contact (lubricant comparison/selection) - Pin-on-disk

- Extreme point-contact sliding conditions - Four-ball tests

- Torque generated during forming, cutting and drilling – Tapping torque

Key Publications with UMT Lubrication

- A Çelik, MT Acar, T Yetim, H Kovacı, AF Yetim. Improving structural, tribological and electrochemical properties of Ti6Al4V alloy with B-doped TiO2 thin films. Tribology International. 146, 106210. (2020).

- AI Costa, L Sousa, AC Alves, F Toptan. Tribocorrosion behaviour of bio-functionalized porous Ti surfaces obtained by two-step anodic treatment. Corrosion Science. 166, 108467. (2020).

- A Li, F Su, PK Chu, J Sun. Articular cartilage inspired bilayer coating on Ti6Al4V alloy with low friction and high load-bearing properties. Applied Surface Science. 515, 146065. (2020).

- AM Delgado-Brito, et al. Effect of the Diffusion Annealing Process on the Sliding Wear Resistance of Cobalt Boride Layer. Journal of Materials Engineering and Performance. 29, 109–125. (2020).

- AM Khan, H Wu, Q Ma, YW Chung, QJ Wang. Relating Tribological Performance and Tribofilm Formation to the Adsorption Strength of Surface-Active Precursors. Tribology Letters. 68, 6. (2020).

- BK Singh, S Samanta, SS Roy, et al. Evaluation of mechanical and frictional properties of CuO added MgO/ZTA ceramics. Materials Research Express. 6, 12. (2020).

- B Li, W Zhang. Synthesis of Ni–Co–ZrO2 nanocomposites doped with ceria particles via electrodeposition as highly protective coating. Journal of Alloys and Compounds. 820, 153158. (2020).

- B Li, W Zhang, T Mei, S Du, D Li, Y Miao. Influence of zirconia and ceria nanoparticles on structure and properties of electrodeposited Ni-W nanocomposites. Composite Structures. 235, 111773. (2020).

- B Li, W Zhang, T Mei, S Du, Y Miao, D Li. Synthesis and properties of YSZ and CeO2 dual nanoparticles doped Ni–B matrix nanocomposite coating. Ceramics International. 46, 6, 8047-8058. (2020).

- B Li, W Zhang, T Mei, Y Miao. Fabrication of Ni–B/TiC–Y2O3 nanocomposites by one-step electrodeposition at different duty cycle and evaluation of structural, surface and performance as protective coating. Journal of Alloys and Compounds. 823, 153888. (2020).

- BP Tonkonogov, AY Kilyakova, et al. Effect of Thickener Nature on Properties of Polyurealubricant Compositions Based on Esters. Chemistry and Technology of Fuels and Oils. 55, 689–696. (2020).

- C Chen, X Feng, Y Shen. Microstructures and properties of TiCp/Al coating synthesized on Ti–6Al–4V alloy substrate using mechanical alloying method. Journal of Alloys and Compounds. 813, 152223. (2020).

- CK Sarangi, BP Sahu, BK Mishra, R Mitra. Pulse electrodeposition and characterization of graphene oxide particle-reinforced Ni–W alloy matrix nanocomposite coatings. Journal of Applied Electrochemistry. 50, 265–279. (2020).

- C Li, X Deng, L Huang, Y Jia, Z Wang. Effect of temperature on microstructure, properties and sliding wear behavior of low alloy wear-resistant martensitic steel. Wear. 442–443, 203125. (2020).

- C Magnus, D Cooper, L Ma, WM Rainforth. Microstructures and intrinsic lubricity of in situ Ti3SiC2–TiSi2–TiC MAX phase composite fabricated by reactive spark plasma sintering (SPS). Wear. 448–449, 203169. (2020).

- CY Su, LK Yeh, CC Lai, KY Li, et al. Effects of lysosomal deposition on the friction coefficient of hydrogel contact lenses. Contact Lens and Anterior Eye. 43, 2, 144-148. (2020).

- C Zhu, B Zhang, S Zheng. Laser cladding nickel‐titanium carbide composite coating on a 45 carbon steel: Preparation, microstructure and wear behavior. Materials Science and Engineering Technology. 51, 2, 247-256. (2020).

- D Choudhury, II Niyonshuti, J Chen, et al. Tribological performance of polydopamine + Ag nanoparticles/PTFE thin films. Tribology International. 144, 106097. (2020).

- D Faria, S Madeira, M Buciumeanu, et al. Novel laser textured surface designs for improved zirconia implants performance. Materials Science and Engineering: C. 108, 110390. (2020).

- D Furmann, et al. The Effect of Synovial Fluid Composition, Speed and Load on Frictional Behaviour of Articular Cartilage. Materials. 13, 6, 1334. (2020).

- E Liu, et al. Effect of Cr2O3 on the microstructure and tribological performance of sprayed Fe-based coating on cylinder liner. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 234, 3. (2020).

- F Zhang, X Zhang, F Zhang, et al. 3D/1D heterostructure of flower-like MoS2 nanospheres anchored on carbon nanotubes for enhanced friction and wear properties as oil additives. Materials Research Express. 6, 12. (2020).

- G Chen, J Zhao, K Chen, S Liu, M Zhang, Y He, J Luo. Ultrastable Lubricating Properties of Robust Self-Repairing Tribofilms Enabled by in Situ-Assembled Polydopamine Nanoparticles. Langmuir. 36, 4, 852–861. (2020).

- G Deng, AK Tieu, X Lan, L Su, L Wang, et al. Effects of normal load and velocity on the dry sliding tribological behaviour of CoCrFeNiMo0.2 high entropy alloy. Tribology International. 144, 106116. (2020).

- G Ren, W Li, H Li, X Fan, L Zhang, M Zhu. Regulating performance characteristics of lithium complex greases via dibasic acids. Lubrication Science. 32, 6, 261-272. (2020).

- HA Raghs, B Kondul, MH Cetin. Investigation of wear behavior of boronized H13 steel under environment of nano-silver-added lubricants coated with different ligands. Surface Topography: Metrology and Properties. 8, 1. (2020).

- H Chen, T Sun, Y Yan, X Ji, Y Sun, X Zhao, J Qi, et al. Cartilage matrix-inspired biomimetic superlubricated nanospheres for treatment of osteoarthritis. Biomaterials. 242, 119931. (2020).

- H Ju, et al. Improvement on the oxidation resistance and tribological properties of molybdenum disulfide film by doping nitrogen. Materials & Design. 186, 108300. (2020).

- H Qiu, H Zhu, J Zhang, Z Xie. Effect of Fe content upon the microstructures and mechanical properties of FexCoNiCu high entropy alloys. Materials Science and Engineering: A. 769, 138514. (2020).

- H Sun, T Li, F Lei, M Yang, D Li, X Huang, et al. Graphite fluoride and fluorographene as a new class of solid lubricant additives for high‐performance polyamide 66 composites with excellent mechanical and tribological properties. Polymer International. 69, 5, 457-466. (2020).

- H Yan, et al. Fabrication and tribological behaviors of Ti3SiC2/Ti5Si3/TiC/Ni-based composite coatings by laser cladding for self-lubricating applications. Optics & Laser Technology. 126, 106077. (2020).

- H Yan, L Zhang, H Li, X Fan, M Zhu. Towards high-performance additive of Ti3C2/graphene hybrid with a novel wrapping structure in epoxy coating. Carbon. 157, 217-233. (2020).

- H Zhang, G Zhou, P Zhong, et al. Experimental investigation on Stribeck curves of different elastic modulus materials under oil and water lubrication conditions. Industrial Lubrication and Tribology. 72, 6. (2020).

- IK Aliyu, MU Azam, DU Lawal, MA Samad. Optimization of SiC Concentration and Process Parameters for a Wear-Resistant UHMWPE Nancocomposite. Arabian Journal for Science and Engineering. 45, 849–860. (2020).

- J Cheng, S Chen, F Zhang, B Shen, X Lu, J Pan. Corrosion- and wear-resistant composite film of graphene and mussel adhesive proteins on carbon steel. Corrosion Science. 164, 108351. (2020).

- J Guo, R Peng, H Du, Y Shen, Y Li, J Li, G Dong. The Application of Nano-MoS2 Quantum Dots as Liquid Lubricant Additive for Tribological Behavior Improvement. Nanomaterials. 10, 2, 200. (2020).

- J Hale, R Lewis, MJ Carré. Rubber friction and the effect of shape. Tribology International. 141, 105911. (2020).

- J Ju, Y Zhou, K Wang, Y Liu, J Li, M Kang, et al. Tribological investigation of additive manufacturing medical Ti6Al4V alloys against Al2O3 ceramic balls in artificial saliva. Journal of the Mechanical Behavior of Biomedical Materials. 104, 103602. (2020).

- JK Xiao, H Tan, YQ Wu, J Chen, C Zhang. Microstructure and wear behavior of FeCoNiCrMn high entropy alloy coating deposited by plasma spraying. Surface and Coatings Technology. 385, 125430. (2020).

- JK Xiao, YQ Wu, J Chen, C Zhang. Microstructure and tribological properties of plasma sprayed FeCoNiCrSiAlx high entropy alloy coatings. Wear. 448–449, 203209. (2020).

- J Li, Z Zhu, Y Peng, G Shen. In Situ Synthesized (Cr, Fe)7C3-Reinforced Composite Coatings via Laser Cladding Deposition of Fe-Based Alloys and Carbon Fibers. Journal of Materials Engineering and Performance. 29, 391–398. (2020).

- J Manhart, A Hausberger, B Maroh, et al. Tribological characteristics of medical gloves in contact with human skin and skin equivalents. Polymer Testing. 82, 106318. (2020).

- J Mao, G Chen, J Zhao, Y He, J Luo. An investigation on the tribological behaviors of steel/copper and steel/steel friction pairs via lubrication with a graphene additive. Friction. (2020).

- JM Li, HJ Wei, LD Wei, DP Zhou, Y Qiu. Extraction of Frictional Vibration Features with Multifractal Detrended Fluctuation Analysis and Friction State Recognition. Symmetry. 12, 2, 272. (2020).

- JN Panda, J Bijwe, RK Pandey. Variation in size of graphite particles and its cascading effect on the performance properties of PAEK composites. Composites Part B: Engineering. 182, 107641. (2020).

- J Ping, X Cui, J Pu, X Jiang, X Zhang, et al. Structural, tribological and corrosion properties of plasma nitrided-chromized-316L stainless steel in air and artificial seawater. Surface Topography: Metrology and Properties. 8, 1. (2020).

- J Tang, S Chen, Y Jia, Y Ma, H Xie, X Quan, Q Ding. Carbon dots as an additive for improving performance in water-based lubricants for amorphous carbon (a-C) coatings. Carbon. 156, 272-281. (2020).

- J Wang, Z Pan, L Wang, L Su, K Carpenter, et al. In-situ dual wire arc additive manufacturing of NiTi-coating on Ti6Al4V alloys: Microstructure characterization and mechanical properties. Surface and Coatings Technology. 386, 125439. (2020).

- J Yang, J Wang, J Guan. Morphology, abrasion and corrosion resistance study of the plasma electrolytic oxidation films formed on pure titanium by adding silane in the electrolyte. Applied Physics A. 126, 288. (2020).

- J Zhang, Z Li, Y Wang, S Zhou, Y Wang, Z Zeng, J Li. A new method to improve the tribological performance of metal nitride coating: A case study for CrN coating. Vacuum. 173, 109158. (2020).

- J Zhao, Y Huang, Y Li, T Gao, Z Dou, et al. Superhigh-exfoliation graphene with a unique two-dimensional (2D) microstructure for lubrication application. Applied Surface Science. 513, 145608. (2020).

- J Zhu, J Qi, D Guan, L Ma, R Dwyer-Joyce. Tribological behaviour of self-lubricating Mg matrix composites reinforced with silicon carbide and tungsten disulfide. Tribology International. 146, 106253. (2020).

- K Balázsi, M Furkó, Z Liao, et al. Graphene added multilayer ceramic sandwich (GMCS) composites: Structure, preparation and properties. Journal of the European Ceramic Society. 40, 14, 4792-4798. (2020).

- K Zhang, X Guo, C Wang, F Liu, L Sun. Effect of plasma-assisted laser pretreatment of hard coatings surface on the physical and chemical bonding between PVD soft and hard coatings and its resulting properties. Applied Surface Science. 509, 145342. (2020).

- L Cheng, Y Wang, G Sun, S Wen, L Deng, H Zhang, et al. Hydration-Enhanced Lubricating Electrospun Nanofibrous Membranes Prevent Tissue Adhesion. Research. (2020).

- L Chen, Z Liu, X Wang, et al. Effects of Surface Roughness Parameters on Tribological Performance for Micro-textured Eutectic Aluminum–Silicon Alloy. J. Tribol. 14, 2, 021702. (2020).

- L Marcinauskas, JS Mathew, et al. Effect of graphite concentration on the tribological performance of alumina coatings. Journal of Alloys and Compounds. 827, 154135. (2020).

- L Tang, et al. Significantly enhanced mechanical and tribological properties of Co-based alloy coatings by annealing treatment. Tribology International. 146, 106265. (2020).

- L Wang, AK Tieu, G Deng, J Wang, BH Tran, et al. In-situ interfacial tribochemistry toward eliminating red-scale of silicon steel in friction process. Tribology International. 143, 106077. (2020).

- L Wang, AK Tieu, H Zhu, G Deng, G Hai, J Wang, et al. The effect of expanded graphite with sodium metasilicate as lubricant at high temperature. Carbon. 159, 345-356. (2020).

- L Wang, AK Tieu, S Cui, G Deng, P Wang, et al. Lubrication mechanism of sodium metasilicate at elevated temperatures through tribo-interface observation. Tribology International. 142, 105972. (2020).

- L Wan, X Tan, T Sun, Y Sun, J Luo, H Zhang. Lubrication and drug release behaviors of mesoporous silica nanoparticles grafted with sulfobetaine-based zwitterionic polymer. Materials Science and Engineering: C. 112, 110886. (2020).

- MA Mekicha, MB de Rooij, et al. The effect of hard chrome plating on iron fines formation. Tribology International. 142, 106003. (2020).

- MA Sainz, S Serena, M Belmonte, et al. Protein adsorption and in vitro behavior of additively manufactured 3D-silicon nitride scaffolds intended for bone tissue engineering. Materials Science and Engineering: C. 115, 110734. (2020).

- M Dinu, L Braic, SC Padmanabhan, et al. Characterization of electron beam deposited Nb2O5 coatings for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials. 103, 103582. (2020).

- M Fernández-Álvarez, F Velasco, A Bautista. Epoxy powder coatings hot mixed with nanoparticles to improve their abrasive wear. Wear. 448–449, 203211. (2020).

- M Fernández-Álvarez, F Velasco, et al. Functionalizing organic powder coatings with nanoparticles through ball milling for wear applications. Applied Surface Science. 513, 145834. (2020).

- ML Pozzebon, CL Lin, PA Meehan. On the Modeling of Wear in Grease-Lubricated Spherical Roller Bearings. Tribology Transactions. 63, 5, 806-819. (2020).

- M Remešová, S Tkachenko, et al. Effects of anodizing conditions and the addition of Al2O3/PTFE particles on the microstructure and the mechanical properties of porous anodic coatings on the AA1050 aluminium alloy. Applied Surface Science. 513, 145780. (2020).

- M Sahul, M Haršáni, et al. Deposition and characterization of Ti-Al-C-N coatings. IOP Conference Series: Materials Science and Engineering. 726. (2020).

- M Sernaglia, D Blanco, AH Battez, JL Viesca, et al. Two fatty acid anion-based ionic liquids - part I: Physicochemical properties and tribological behavior as neat lubricants. Journal of Molecular Liquids. 305, 112827. (2020).

- M Shen, B Li, D Ji, G Xiong, L Zhao, J Zhang, Z Zhang. Effect of Particle Size on Tribological Properties of Rubber/Steel Seal Pairs Under Contaminated Water Lubrication Conditions. Tribology Letters. 68, 40. (2020).

- N Hu, X Zhang, X Wang, N Wu, S Wang. Study on Tribological Properties and Mechanisms of Different Morphology WS2 as Lubricant Additives. Materials. 13, 7, 1522. (2020).

- O Çomakli. Influence of CrN, TiAlN monolayers and TiAlN/CrN multilayer ceramic films on structural, mechanical and tribological behavior of β-type Ti45Nb alloys. Ceramics International. 46, 6, 8185-8191. (2020).

- P Huang, R Zhu, C Li, X Wang, X Wang, X Zhang. Effect of graphene concentration on tribological properties of graphene aerogel/TiO2 composite through controllable cellular-structure. Materials & Design. 188, 108468. (2020).

- PL Fuhrmann, G Sala, E Scholten, M Stieger. Influence of clustering of protein-stabilised oil droplets with proanthocyanidins on mechanical, tribological and sensory properties of o/w emulsions and emulsion-filled gels. Food Hydrocolloids. 105, 105856. (2020).

- PL Fuhrmann, M Aguayo-Mendoza, et al. Characterisation of friction behaviour of intact soft solid foods and food boli. Food Hydrocolloids. 100, 105441. (2020).

- P Shi, et al. TiO2–ZnO/Ni–5wt.%Al composite coatings on GH4169 superalloys by atmospheric plasma spray techniques and theirs elevated-temperature tribological behavior. Ceramics International. 46, 9, 13527-13538. (2020).

- P Zhang, G Zhao, W Wang, B Wang, P Shi, G Qi, G Yi. Study on the Mechanical and Tribological Properties and the Mechanisms of Cr-Free Ni-Based Self-Lubricating Composites at a Wide Temperature Range. Metals. 10, 2, 268. (2020).

- Q Zhang, B Wu, R Song, H Song, J Zhang, X Hu. Preparation, characterization and tribological properties of polyalphaolefin with magnetic reduced graphene oxide/Fe3O4. Tribology International. 141, 105952. (2020).

- RK Mittal, et al. Machining Response and Damage Evolution of Amorphous Carbon Coated Tools in High-Speed Micromilling of Ti–6Al–4V. J. Micro Nano-Manuf. 8, 2, 024507-02412. (2020).

- R Kumar, B Malaval, M Antonov, G Zhao. Performance of polyimide and PTFE based composites under sliding, erosive and high stress abrasive conditions. Tribology International. 147, 106282. (2020).

- R Kumar, M Antonov, U Beste, D Goljandin. Assessment of 3D printed steels and composites intended for wear applications in abrasive, dry or slurry erosive conditions. International Journal of Refractory Metals and Hard Materials. 86, 105126. (2020).

- R Kumar, M Antonov, Y Holovenko, A Surzenkov. Erosive Wear Resistance of Nature-inspired Flexible Materials. Tribology Letters. 68, 51. (2020).

- R Qiang, K Hou, J Wang, S Yang. Smooth and dense graphene quantum dots-based lubricating coatings prepared by electrophoretic deposition. Applied Surface Science. 509, 145338. (2020).

- S Huang, X Li, B Yu, Z Jiang, H Huang. Machining characteristics and mechanism of GO/SiO2 nanoslurries in fixed abrasive lapping. Journal of Materials Processing Technology. 277, 116444. (2020).

- S Liu, S Ruan, X Huang, A Ortiz, S Jiang, J Liu. Micro/Nano-tribological Properties of Binary-Doped Ionic Liquid Lubricating Films on Alkyl Silane-Modified Silicon Surfaces. Tribology Letters. 68, 12. (2020).

- S Madeira, A Barbosa, CG Moura, et al. Aunps and Agμps-functionalized zirconia surfaces by hybrid laser technology for dental implants. Ceramics International. 46, 6, 7109-7121. (2020).

- SN Gorbacheva, YM Yarmush, SO Ilyin. Rheology and tribology of ester-based greases with microcrystalline cellulose and organomodified montmorillonite. Tribology International. 148, 106318. (2020).

- S Qi, Z Geng, Z Lu, G Zhang, et al. Synergistic Lubricating Behaviors of 3D Graphene and 2D Hexagonal Boron Nitride Dispersed in PAO4 for Steel/Steel Contact. Advanced Materials Interfaces. 7, 8, 1901893. (2020).

- S Singh, X Chen, C Zhang, RK Gautam, et al. Nickel-catalyzed direct growth of graphene on bearing steel (GCr15) by thermal chemical vapor deposition and its tribological behavior. Applied Surface Science. 502, 144135. (2020).

- S Wan, BH Tran, AK Tieu, HTT Ta, H Zhu, et al. Probing tribo-interface evolution governing high temperature tribology of nitride ceramic contacts. Materials Characterization. 160, 2020, 110062. (2020).

- T Mishra, et al. A material point method based ploughing model to study the effect of asperity geometry on the ploughing behaviour of an elliptical asperity. Tribology International. 142, 106017. (2020).

- TSNS Narayanan, J Kim, HW Park. High performance corrosion and wear resistant Ti-6Al-4V alloy by the hybrid treatment method. Applied Surface Science. 504, 144388. (2020).

- T Zhang, J Guo, JF Chen, JM Wang, et al. Heat stability and rheological properties of concentrated soy protein/egg white protein composite microparticle dispersions. Food Hydrocolloids. 100, 105449. (2020).

- UN Marathe, J Bijwe. High performance polymer composites - Influence of processing technique on the fiber length and performance properties. Wear. 446–447, 203189. (2020).

- V Writzl, AC Rovani, G Pintaude, et al. Scratch resistances of compacted graphite iron with plasma nitriding, laser hardening, and duplex surface treatments. Tribology International. 143, 106081. (2020).

- W Li, et al. Investigating the fluorination degree of FG nanosheets on the tribological properties of FG/PI composite coatings. Progress in Organic Coatings. 139, 105481. (2020).

- W Qi, P Huang, X Chen, J Jin, J Luo. Achieving controllable friction of ultrafine-grained graphite HPG510 by tailoring the interfacial nanostructures. Applied Surface Science. 512, 145731. (2020).

- W Yu, J Wang, W Huang, L Cui, L Wang. Improving high temperature tribological performances of Si doped diamond-like carbon by using W interlayer. Tribology International. 146, 106241. (2020).

- X Feng, C Lu, J Jia, J Xue, Q Wang, Y Sun, et al. High temperature tribological behaviors and wear mechanisms of NiAl–NbC–Ag composites formed by in-situ decomposition of AgNbO3. Tribology International. 141, 105898. (2020).

- X Hao, P Sun, S Xiao, Y Yang, L Li. Tribological performance of surface with different wettability under ball-on-disc test. Applied Surface Science. 501, 144228. (2020).

- X Han, Z Zhang, SJ Thrush, GC Barber, H Qu. Ionic liquid stabilized nanoparticle additive in a steel-ceramic contact for extreme pressure application. Wear. 452–453, 203264. (2020).

- X Li, J Deng, D Ge, H Yue. Rapid crystallization of electrohydrodynamically atomized ZrO2 thin films by laser annealing. Applied Surface Science. 510, 145510. (2020).

- Y Bai, S He, Y Lian, T Yu, C Dai, J Zhao, H Zhang. Self-Lubricating Supramolecular Hydrogel for In-Depth Profile Control in Fractured Reservoirs. ACS Omega. 5, 13, 7244–7253. (2020).

- Y Liu, D Xiong, X Zhao.Improved biotribological properties of polyetheretherketone composites for artificial joints with a ‘soft-on-hard’ structure and brushlike molecules. Tribology International. 145, 106165. (2020)

- Y Mu, E Simonetto, M Scagnolari, A Ghiotti. Wear in Hot Stamping by Partition Heating. J. Manuf. Mater. Process. 4, 1, 18. (2020).

- Y Xi, HJ Kaper, CH Choi, PK Sharma. Tribological properties of microporous polydimethylsiloxane (PDMS) surfaces under physiological conditions. Journal of Colloid and Interface Science. 561, 220-230. (2020).

- Y Xu, RL Jackson, Y Chen, et al. A comparison of nanoscale measurements with the theoretical models of real and nominal contact areas. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 234, 11. (2020).

- Y Zhang, et al. One step synthesis of ZnO nanoparticles from ZDDP and its tribological properties in steel-aluminum contacts. Tribology International. 141, 105890. (2020).

- Y Zhao, K Feng, C Yao, Z Li. Effect of MoO3 on the microstructure and tribological properties of laser-clad Ni60/nanoCu/h-BN/MoO3 composite coatings over wide temperature range. Surface and Coatings Technology. 387, 125477. (2020).

- Z Cai, R Chen, J Qian, S Zheng, et al. Improving scratch-resistance and wear-resistance of VN film by deep cryogenic treatment with liquid nitrogen. Surface Engineering. 36,2. (2020).

- Z Li, H Zhang, W He, C Ma, X Nie, Y Li. Tribological performance of a novel wide-temperature applicable a-C/(WC/a-C) film against M50 steel. Tribology International. 145, 106189. (2020).

- Z Mou, B Wang, Z Huang, H Lu. Ultrahigh yield synthesis of mesoporous carbon nanoparticles as a superior lubricant additive for polyethylene glycol. Dalton Transactions. (2020).

- Z Wang, J Li, Y Liu, J Luo. Macroscale superlubricity achieved between zwitterionic copolymer hydrogel and sapphire in water. Materials & Design. 188, 108441. (2020).

- Z Wang, J Li, Y Liu, J Luo. Synthesis and characterizations of zwitterionic copolymer hydrogels with excellent lubrication behavior. Tribology International. 143, 106026. (2020).

- Z Wang, Y Yan, Y Wang, Y Su, L Qiao. Lifecycle of cobalt-based alloy for artificial joints: From bulk material to nanoparticles and ions due to bio-tribocorrosion. Journal of Materials Science & Technology. 46, 98-106. (2020).

- A Ahmad, A Imani, L Mao, R Iqbal, et al. A Bifunctional and Free‐Standing Organic Composite Film with High Flexibility and Good Tensile Strength for Tribological and Electrochemical Applications. Advanced Materials Technologies. 4, 10, (2019).

- A Ahmadi, J Tang, VG Pol, F Sadeghi, KK Mistry. Binder mediated enhanced surface adhesion of cured, dry solid lubricant on bearing steel for significant friction and wear reduction under high contact pressure. Carbon. 146, 588-596. (2019).

- AA Novikova, et al. Influence of glycerol dispersions of graphene oxide on the friction of rough steel surfaces. Journal of Molecular Liquids. 284, 1-11. (2019).

- A Bogatov, et al. Transition from Self-Organized Criticality into Self-Organization during Sliding Si3N4 Balls against Nanocrystalline Diamond Films. Entropy. 21, 11, 1055. (2019).

- A de Moura Silva, VMG de Figueiredo, et al. Diamond-like carbon films over reconstructive TMJ prosthetic materials: Effects in the cytotoxicity, chemical and mechanical properties. Journal of Oral Biology and Craniofacial Research. 9, 3, 201-207. (2019).

- AFF Oliveira, F Toptan. Wear Behavior of Ti-Al2O3 Biocomposites in 9 g/L NaCl Solution. Journal of Materials Engineering and Performance. 28, 6000–6010. (2019).

- A Jain, A Singh, AP Singh. Effect of tribological parameters on sliding wear and friction coefficient which relates to preload loss in tapered roller bearing. Industrial Lubrication and Tribology. 71, 1. (2019).

- A Morales, O Piamba, J Olaya. Influence of Gas Pressure on the Mechanical and Tribological Properties of Cu-Al Coatings Deposited via Thermal Spray. Coatings. 9, 11, 722. (2019).

- ARK Rana, Z Farhat. Preparation and tribological characterization of graphene incorporated electroless Ni-P composite coatings. Surface and Coatings Technology. 369, 334-346. (2019).

- AY Adesina, ZM Gasem, AS Mohammed. Comparative Investigation and Characterization of the Scratch and Wear Resistance Behavior of TiN, CrN, AlTiN and AlCrN Cathodic Arc PVD Coatings. Arabian Journal for Science and Engineering. 44, 10355–10371. (2019).

- A Yamazaki, K Inagaki. Laminated film. Google Patents. US20190054724A1. (2019).

- B Li, W Zhang. A novel Ni-B/YSZ nanocomposite coating prepared by a simple one-step electrodeposition at different duty cycles. Journal of Materials Research and Technology. 9, 2, 1519-1529. (2019).

- B Wang, X Han, GC Barber, Y Pan. Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness. Metals. 9, 12, 1329. (2019).

- C Gan, T Liang, W Li, X Fan, M Zhu. Amine-terminated ionic liquid modified graphene oxide/copper nanocomposite toward efficient lubrication. Applied Surface Science. 491, 105-115. (2019).

- C Humelnicu, S Ciortan, V Amortila. Artificial Neural Network-Based Analysis of the Tribological Behavior of Vegetable Oil–Diesel Fuel Mixtures. Lubricants 2019, 7, 4, 32. (2019).

- C Liu, O Friedman, Y Li, S Li, Y Tian, Y Golan, Y Meng. Electric Response of CuS Nanoparticle Lubricant Additives: The Effect of Crystalline and Amorphous Octadecylamine Surfactant Capping Layers. Langmuir, 35, 48, 15825–15833. (2019).

- C Magnus, D Cooper, J Sharp, WM Rainforth. Microstructural evolution and wear mechanism of Ti3AlC2–Ti2AlC dual MAX phase composite consolidated by spark plasma sintering (SPS). Wear. 438-439, 203013. (2019).

- C Magnus, T Kwamman, WM Rainforth. Dry sliding friction and wear behaviour of TiC-based ceramics and consequent effect of the evolution of grain buckling on wear mechanism. Wear. 422–423, 54-67. (2019).

- C Magnus, WM Rainforth. Spark plasma sintering (SPS) synthesis and tribological behaviour of MAX phase composite of the family Tin+1SiCn (n = 2). Wear. 438–439, 203062. (2019).

- C Tao. Tribological Characteristics of Multiple Nanofluids Applied on Brass. ProQuest. (2019).

- C Wang, et al. Tribological behavior of Ti-6Al-4V against cortical bone in different biolubricants. Journal of the Mechanical Behavior of Biomedical Materials. 90, 460-471. (2019).

- C Wang, G Zhang, Z Li, Y Xu, X Zeng, S Zhao, et al. Microtribological properties of Tisingle bond6Alsingle bond4V alloy treated with self-assembled dopamine and graphene oxide coatings. Tribology International. 137, 46-58. (2019).

- C Wang, T Stiller, et al. Correlation of Tribological Behavior and Fatigue Properties of Filled and Unfilled TPUs. Lubricants. 7, 7, 60. (2019).

- C Xiao, et al. Gradual degeneration of liquid superlubricity: Transition from superlubricity to ordinary lubrication, and lubrication failure. Tribology International. 130, 352-358. (2019).

- C Xiao, J Li, L Chen, C Zhang, N Zhou, T Qing, L Qian et al. Water-based superlubricity in vacuum. Friction. 7, 192–198. (2019).

- CX Lin, W Li, HY Deng, K Li, ZR Zhou. Friction Behavior of Esophageal Mucosa Under Axial and Circumferential Extension. Tribology Letters. 67, 9. (2019).

- C Xue, S Wang, D Wen, G Wang, Y Wang. Tribological Performance of Nanocomposite Carbon Lubricant Additive. Materials. 12, 1, 149. (2019).

- CY Su, et al. Poly-Gamma-Glutamic Acid Functions as an Effective Lubricant with Antimicrobial Activity in Multipurpose Contact Lens Care Solutions. Polymers. 11, 6, 1050. (2019).

- C Zhang, M Zheng, Y Wang, P Gao, B Gan. Effect of high energy shot peening on the wear resistance of TiN films on a TA2 surface. Surface and Coatings Technology. 378, 124821. (2019).

- D Dobrocký, et al. Surface Structure Evaluation of Functional Surfaces after Plasma Nitriding of Barrel Steel 42CrMo4. ECS Transactions. 95, 1. (2019).

- D Ernens, D Westerwaal, RFH Roijmans, et al. Evaluation of the Elevated-Temperature Performance and Degradation Mechanisms of Thread Compounds. SPE Drilling & Completion. 34, 03. (2019).

- D Ernens, EJ van Riet, et al. The Role of Phosphate-Conversion Coatings in the Makeup and Sealing Ability of Casing Connections. 31, 1. (2019).

- D Guo, et al. Hydrophilic Poly(vinylidene Fluoride) Film with Enhanced Inner Channels for Both Water- and Ionic Liquid-Driven Ion-Exchange Polymer Metal Composite Actuators. ACS Appl. Mater. Interfaces. 11, 2, 2386–2397. (2019).

- D Medveď, J Balko, R Sedlák, A Kovalčíková, et al. Wear resistance of ZrB2 based ceramic composites. International Journal of Refractory Metals and Hard Materials. 81, 214-224. (2019).

- D Ning, A Zhang, H Wu. Enhanced Wear Performance of Cu-Carbon Nanotubes Composite Coatings Prepared by Jet Electrodeposition. Materials. 12, 3, 392. (2019).

- DTA Matthews, et al. An Overview: Laser-Based Additive Manufacturing for High Temperature Tribology. Front. Mech. Eng. 5, 16. (2019).

- D Zhang, et al. Microstructure and properties of tin-cobalt nanocomposite coatings reinforced by titanium dioxide nanoparticles. Materials Research Express. 6, 12. (2019).

- D Zhang, et al. Tribological Performance of Polymer Composite Coatings Modified With La2O3 and MoS2 Nanoparticles. J. Tribol. 141, 11, 111601-111610. (2019).

- EC Serra, et al. Influence of WS2 content on high temperature wear performance of magnetron sputtered TiN-WSx thin films. Ceramics International. 45, 6, 19918-19924. (2019).

- E Harea, R Stoček, L Storozhuk, et al. Study of tribological properties of natural rubber containing carbon nanotubes and carbon black as hybrid fillers. Applied Nanoscience. 9, 899–906. (2019).

- E Liu, et al. Tribocorrosion behaviors of thermal spraying WC/Ni60 coated 316L stainless steel in artificial seawater. Industrial Lubrication and Tribology. 71, 6. (2019).

- F Bartolomeu, et al. Implant surface design for improved implant stability – A study on Ti6Al4V dense and cellular structures produced by Selective Laser Melting. Tribology International. 129, 272-282. (2019).

- F Bartolomeu, et al. Multi-material Ti6Al4V & PEEK cellular structures produced by Selective Laser Melting and Hot Pressing: A tribocorrosion study targeting orthopedic applications. Journal of the Mechanical Behavior of Biomedical Materials. 89, 54-64. (2019).

- F Bartolomeu, et al. Ti6Al4V-PEEK multi-material structures – design, fabrication and tribological characterization focused on orthopedic implants. Tribology International. 131, 672-678. (2019).

- FJ Carrión, et al. Diprotic ammonium palmitate ionic liquid crystal and nanodiamonds in aqueous lubrication. Film thickness and influence of sliding speed. Wear. 418–419, 241-252. (2019).

- F Chen, et al. Light-triggered pH/thermal multisensitive polyelectrolyte/ITO glass hybrid electrode. Applied Surface Science. 464, 273-279. (2019).

- F Jiang, H Sun, L Chen, F Lei, D Sun. Dispersion-tribological property relationship in mineral oils containing 2D layered α-zirconium phosphate nanoplatelets. Friction. 8, 695–707. (2019).

- F Lei, et al. Microwave-assisted liquid phase exfoliation of graphite fluoride into fluorographene. Chemical Engineering Journal. 360, 673-679. (2019).

- F Yang, MQ Xue. Facile Solvothermal Preparation and Tribological Performance of PbSe Nanoparticles. Micro and Nanosystems. 11, 6, 34-39. (2019).

- F Yin, X Zhou, S Nie, H Ji, Z Hu. Tribocorrosion Behavior of Several Corrosion-resistant Alloys Sliding Against CF-PEEK: Application for Hydraulic Valve in Seawater. Int. J. Electrochem. Sci. 14, 4643 – 4658. (2019).

- F Zhang, et al. Synthesis and tribological properties of NbSe2/CeNbO4 nanocomposite. Materials Research Express. 6, 9. (2019).

- F Zhang, G Tang, J Xu, C Li. Solvothermal preparation and tribological performance of g-C3N4/TiO2 hybrids as oil-based lubricant additives. Micro & Nano Letters. 14, 13, 1355 – 1360. (2019).

- G Boidi. An experimental assessment of surface micro irregularities (porosity and texture) effects on tribological behaviour under lubricated conditions. Escola Politécnica. (2019).

- GC Verma, et al. An experimental study on surface roughness and frictional property of ultrasonic-vibration-assisted milled surface. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 233, 12. (2019).

- G Fiaschi, A Rota, A Ballestrazzi, D Marchetto, et al. A Chemical, Mechanical, and Tribological Analysis of DLC Coatings Deposited by Magnetron Sputtering. Lubricants. 7, 4, 38. (2019).

- G Kaya, F Yildiz, İ Hacisalihoğlu. Characterization of the Structural and Tribological Properties of Medical Ti6Al4V Alloy Produced in Different Production Parameters Using Selective Laser Melting. 3D Printing and Additive Manufacturing. 6, 5. (2019).

- G Liu, L Zhang, G Li, F Zhao, Q Che, C Wang, G Zhang. Tuning the tribofilm nanostructures of polymer-on-metal joint replacements for simultaneously enhancing anti-wear performance and corrosion resistance. Acta Biomaterialia. 87, 285-295. (2019).

- G Paul, S Shit, H Hirani, T Kuila, NC Murmu. Tribological behavior of dodecylamine functionalized graphene nanosheets dispersed engine oil nanolubricants. Tribology International. 131, 605-619. (2019).

- G Tang, F Su, X Xu, PK Chu. 2D black phosphorus dotted with silver nanoparticles: An excellent lubricant additive for tribological applications. Chemical Engineering Journal. 392, 123631. (2019).

- HB Na, LH Xu, GC Han, SK Liu, LH Lu. Machinability Research on the Micro-Milling for Graphene Nano-Flakes Reinforced Aluminum Alloy. Metals. 9, 10, 1102. (2019).

- H Chen, X Xie, Y Wang, Y Wang, Y Ye. Understanding corrosion and tribology behaviors of VN and VCN coatings in seawater. Tungsten. 1, 110–119. (2019).

- H Liu, C Jiang, M Chen, L Wang, V Ji. Surface layer microstructures and wear properties modifications of Mg-8Gd-3Y alloy treated by shot peening. Materials Characterization. 158, 109952. (2019).

- H Ju, et al. Crystal structure and tribological properties of Zrsingle bondAlsingle bondMosingle bondN composite films deposited by magnetron sputtering. Materials Chemistry and Physics. 230, 347-354. (2019).

- H Ju, N Ding, J Xu, L Yu, Y Geng, F Ahmed, B Zuo, et al. The influence of crystal structure and the enhancement of mechanical and frictional properties of titanium nitride film by addition of ruthenium. Applied Surface Science. 489, 247-254. (2019).

- H Ju, N Ding, J Xu, L Yu, Y Geng, F Ahmed. The tribological behavior of niobium nitride and silver composite films at elevated testing temperatures. Materials Chemistry and Physics. 237, 121840. (2019).

- H Kovacı. Comparison of the microstructural, mechanical and wear properties of plasma oxidized Cp-Ti prepared by laser powder bed fusion additive manufacturing and forging processes. Surface and Coatings Technology. 374, 987-996. (2019).

- H Kovacı, et al. The effect of surface plastic deformation produced by shot peening on corrosion behavior of a low-alloy steel. Surface and Coatings Technology. 360, 78-86 (2019).

- H Kovacı, İ Hacısalihoğlu, AF Yetim, A Çelik. Effects of shot peening pre-treatment and plasma nitriding parameters on the structural, mechanical and tribological properties of AISI 4140 low-alloy steel. Surface and Coatings Technology. 358, 256-265. (2019).

- H Guo, B Li, C Lu, Q Zhou, J Jia. Effect of WC–Co content on the microstructure and properties of NiCrBSi composite coatings fabricated by supersonic plasma spraying. Journal of Alloys and Compounds. 789, 966-975. (2019).

- HR Alanagh, et al. Biomineralized coordinated metal polymers in epoxy for high mechanical and tribological properties. Composites Part A: Applied Science and Manufacturing. 123, 37-45. (2019).

- Huangjie Zhou Dangsheng Xiong Wei Tong Zhibing Shi Xiaoya Xiong. Lubrication behaviors of PVA‐casted LSPEEK hydrogels in artificial cartilage repair. Applied Polymer Science. 136, 47944. (2019).

- H Wang, et al. Superhydrophobic UHMWPE/nanosilica composite films on glass and silicon and their tribological behavior. Surface Topography: Metrology and Properties. 7, 1. (2019).

- H Wang, et al. Superlubricity of Polyalkylene Glycol Aqueous Solutions Enabled by Ultrathin Layered Double Hydroxide Nanosheets. ACS Appl. Mater. Interfaces. 11, 22, 20249–20256. (2019).

- H Wan, K Ren, H Kaper, PK Sharma. Bioinspired Muco-Adhesive Restores Lubrication of Degraded Cartilage through reestablishment of lamina splendens. (2019).

- H Wu, et al. Formation and Nature of Carbon-Containing Tribofilms. CS Appl. Mater. Interfaces. 11, 17, 16139–16146. (2019).

- HX Trinh, K Shibuya. Theoretical Foundation for Design of Friction-Tunable Soft Finger With Wrinkle's Morphology. EEE Robotics and Automation Letters.. 4,4, 4027-4034. (2019).

- H Yang, L Zhao, S Xue, Z Deng, J Li, X Zeng. Branch-chain length modulated graphene oxides for regulating the physicochemical and tribophysical properties of pickering emulsions. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 579, 123703. (2019).

- H Yang, Q Mo, W Li, F Gu. Preparation and Properties of Self-Healing and Self-Lubricating Epoxy Coatings with Polyurethane Microcapsules Containing Bifunctional Linseed Oil. Polymers, 11, 10, 1578. (2019).

- H Yang, S Xue, J Zhou, J Li, X Zeng. Interfacial Assembly Behavior of Alkylamine-Modulated Graphene Oxide with Different Oxidation Degrees. Langmuir. 35, 40, 12936–12946. (2019).

- H Zhang, T Ni. Influence of coupling agent on water-based lubricating properties of konjac glucomannan. Agriculture Academy. 64-71. (2019).

- H Zhao, Y Liu, B Xu, Y Lu, C Zhou, X Wu, J Li. Fabrication and tribological properties of a self-lubricating wear-resistant coating based on structural coupling. Ceramics International. 45, 3, 3910-3920. (2019).

- I Campos-Silva, RC Vega-Morón, et al. Dry Sliding Wear Resistance of Cobalt Boride Coatings Formed on ASTM F1537 Alloy. Journal of Materials Engineering and Performance. 28, 2399–2410. (2019).

- I Farias, L Olmos, O Jimenez, M Flores, A Braem, et al. Wear modes in open porosity titanium matrix composites with TiC addition processed by spark plasma sintering. Transactions of Nonferrous Metals Society of China. 29, 8, 1653-1664. (2019).

- I Garcia, S Guerra, J de Damborenea, A Conde. Reduction of the Coefficient of Friction of Steel-Steel Tribological Contacts by Novel Graphene-Deep Eutectic Solvents (DESs) Lubricants. Lubricants, 7, 4, 37. (2019).

- IK Aliyu, AS Mohammed, A Al‐Qutub. Tribological performance of ultra high molecular weight polyethylene nanocomposites reinforced with graphene nanoplatelets. Polymer Composites. 40, S2. (2019).

- I Tudela, AJ Cobley, Y Zhang. Tribological performance of novel nickel-based composite coatings with lubricant particles. 7, 169–180. (2019).

- JA Patten, H Mohammadi. Laser augmented diamond drilling apparatus and method. Google Patents. US10183337B2. (2019).

- J Chen, L Zeng, Q Wan, K Chen, Y Lu. Effects of texture geometry on the tribological performance of brass with a TiN coating under lubricated rotation. AIP Advances. 9, 105116 (2019).

- J Chen, H Yang, J Li, J Chen, Y Zhang, et al. The development of an artificial skin model and its frictional interaction with wound dressings. Journal of the Mechanical Behavior of Biomedical Materials. 94, 308-316. (2019).

- J Chen, W Cai. Effect of scratching frequency on the tribocorrosion resistance of Al-Mn amorphous thin films. Wear. 426–427, Part B, 1457-1465. (2019).

- J Duan, F Ye, H Zhao. The study of the tribological properties of TiAgN/W2N coatings in a wide temperature range. Material Research Express. 6, 12. (2019).

- J Gao, S Zhang, H Jin, Y Shen. Fabrication of Al7075/PI composites base on FSW technology. The International Journal of Advanced Manufacturing Technology. 104, 4377–4386. (2019).

- J Guo, et al. Laser cladding NiCrBSi/TiN/h-BN self-lubricating wear resistant coating on Ti–6Al–4V surface. Materials Research Express. 6, 6. (2019).

- J Jin, W Wang, X Chen. Microstructure and Mechanical Properties of Ti + N Ion Implanted Cronidur30 Steel. Materials. 12, 3, 427. (2019).

- J Klein, R Goldberg, N Iuster, R Sorkin. Low friction hydrogels and hydrogel-containing composite materials. Google Patents. US10314946B2. (2019).

- JK Xiao, YQ Wu, W Zhang, J Chen, et al. Microstructure, wear and corrosion behaviors of plasma sprayed NiCrBSi-Zr coating. Surface and Coatings Technology. 360, 172-180. (2019).

- JL do Vale, CH da Silva, G Pintaude. Energetic coefficient of friction applied to cylinder liners lab tests. Industrial Lubrication and Tribology. 72, 9. (2019).

- JL do Vale, CH da Silva, G Pintaude. Tribological performance assessment of lamellar and compacted graphite irons in lubricated ring-on-cylinder test. Wear. 426–427, 471-480. (2019).

- J Li, Z Zhu, Y Peng, G Shen. Effect of Carbon Fiber Addition on the Microstructure and Wear Resistance of Laser Cladding Composite Coatings. Coatings. 9, 10, 684. (2019).

- JN Panda, J Bijwe, RK Pandey. Exploring the tribo-potential of nano and micron-sized particles of potassium titanate in PAEK based composite. Surface Topography: Metrology and Properties. 7, 2. (2019).

- JN Panda, J Bijwe, RK Pandey. Optimization of graphite contents in PAEK composites for best combination of performance properties. Composites Part B: Engineering. 174, 106951. (2019).

- JN Panda, J Bijwe, RK Pandey. Optimization of the amount of short glass fibers for superior wear performance of PAEK composites. Composites Part A: Applied Science and Manufacturing. 116, 158-168. (2019).

- JN Panda, J Bijwe, RK Pandey. Surface Topography: Metrology and Properties. 7, 3. (2019).

- JQ Liu, ZY Wu, HT Cao, F Wen, YT Pei. Effect of bias voltage on the tribological and sealing properties of rubber seals modified by DLC films. Surface and Coatings Technology. 360, 391-399. (2019).

- JQ Liu, LJ Li, B Wei, F Wen, HT Cao, YT Pei. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of DLC films coated on rubber by magnetron sputtering. Surface and Coatings Technology. 365, 33-40. (2019).

- J Qian, S Li, J Pu, Z Cai, H Wang, Q Cai, P Ju. Effect of heat treatment on structure and properties of molybdenum nitride and molybdenum carbonitride films prepared by magnetron sputtering. Surface and Coatings Technology. 374, 725-735. (2019).

- J Sun, A Li, F Su. Excellent Lubricating Ability of Functionalization Graphene Dispersed in Perfluoropolyether for Titanium Alloy. ACS Applied Nano Materials. 2, 3, 1391–1401. (2019).

- J Ureña, et al. Dry sliding wear behaviour of β-type Ti-Nb and Ti-Mo surfaces designed by diffusion treatments for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials. 91, 335-344. (2019).

- J Wang, H Ge, X Wang, Y Shen, T Liu, et al. Effect of Clay and Organic Matter Content on the Shear Slip Properties of Shale. JGR Solid Earth. 124, 9, 9505-9525. (2019).

- J Wu, D Zhang, et al. Long-term stability and salt-responsive behavior of polyzwitterionic brushes with cross-linked structure. Progress in Organic Coatings. 134, 153-161. (2019).

- J Zhang, D Yang, A Rosenkranz, et al. Laser Surface Texturing of Stainless Steel − Effect of Pulse Duration on Texture's Morphology and Frictional Response. Advanced Engineering Materials. 21, 3. (2019).

- J Zhang, S Zhou, Y Wang, Y Wang, C Wang, et al. Enhancing anti-corrosion and antifouling properties of Cu/GLC composite film for marine application. Surface and Coatings Technology. 375, 414-426. (2019).

- J Zhao, et al. Nickel-based Gradient Coating on Copper Prepared by the Combination of Laser Alloying and Laser Cladding Technologies. Lasers in Engineering (Old City Publishing). 42, 4-6, 363-380. 18p. (2019).

- J Zhao, G Chen, Y He, S Li, Z Duan, Y Li, J Luo. A novel route to the synthesis of an Fe3O4/h-BN 2D nanocomposite as a lubricant additive. RSC advances. (2019).

- J Zhao, G Yang, C Zhang, Y Zhang, S Zhang, P Zhang. Synthesis of water-soluble Cu nanoparticles and evaluation of their tribological properties and thermal conductivity as a water-based additive. Friction. 7, 246–259. (2019).

- J Zhao, G Yang, Y Zhang, S Zhang, P Zhang. A Simple Preparation of HDA-CuS Nanoparticles and Their Tribological Properties as a Water-Based Lubrication Additive. Tribology Letters. 67, 88. (2019).

- J Zhao, Y Li, Y He, J Luo. In Situ Green Synthesis of the New Sandwichlike Nanostructure of Mn3O4/Graphene as Lubricant Additives. ACS Appl. Mater. Interfaces. 11, 40, 36931–36938. (2019).

- KC Sanjeev, et al. Tribological behavior of 17–4 PH stainless steel fabricated by traditional manufacturing and laser-based additive manufacturing methods. Wear. 440–441, 203100. (2019).

- Keisuke Sato, Hikaru Okubo, Yuki Hirata, Chiharu Tadokoro, Ken Nakano, Yoshinobu Tsujii, Shinya Sasaki. Macroscopic tribological properties of thick concentrated polymer brush on rough steel under lubrication with ionic liquid. Jurnal Tribologi. 20, 97-113. (2019).

- K Fallahnezhad, S Liu, O Brinji, M Marker, PA Meehan. Monitoring and modelling of false brinelling for railway bearings. Wear. 424–425, 151-164.

- K Gu, et al. Microstructure, mechanical and tribological properties of DLC/Cu-DLC/W-DLC composite films on SUS304 stainless steel substrates. Materials Research Express. 6, 8. (2019).

- K Li, et al. Effect of oxidation time on the short time oxidation behavior and tribological performance of bulk Fe2B. Materials Research Express. 6, 10. (2019).

- K Zhang, J Deng, Y Xing, X Guo. INFLUENCE OF POST-LASER PROCESSING ON THE MECHANICAL AND TRIBOLOGICAL PROPERTIES OF PVD TiAlN COATINGS. Surface Review and Letters. 27, 04, 1950137. (2019).

- L Alhadeff, M Marshall, T Slatter. The influence of tool coating on the length of the normal operating region (steady-state wear) for micro end mills. Precision Engineering. 60, 306-319. (2019).

- LA Urtis, et al. Influence of Water on Tribolayer Growth When Lubricating Steel with a Fluorinated Phosphonium Dicyanamide Ionic Liquid. Lubricants. 7, 3, 27. (2019).

- L Biasetto, et al. Use of cryogenic machining to improve the adhesion of sphene bioceramic coatings on titanium substrates for dental and orthopaedic applications. Ceramics International. 45, 5, 5941-5951. (2019).

- L Chen, L Ge, L Fan, R Guo. Microstructure and Tribological Properties of Lamellar Liquid Crystals Formed by Ionic Liquids as Cosurfactants. Langmuir. 35, 11, 4037–4045. (2019).

- L Chen, Z Liu, B Wang, Q Song, Y Wan, L Chen. Surface Characterization and Tribological Performance of Anodizing Micro-Textured Aluminum-Silicon Alloys. Materials. 2019, 12, 11, 1862. (2019).

- L Ding, J Zhu, Q Zhao, B Liu. Preparation and Characterization of Composite Resin Containing Anion Powder. Journal of Physics: Conference Series. 1187, 3. (2019).

- L Fan, Y Dong, H Chen, L Dong, Y Yin. Wear Properties of Plasma Transferred Arc Fe-based Coatings Reinforced by Spherical WC Particles. Journal of Wuhan University of Technology-Mater. Sci. Ed. 34, 433–439. (2019).

- L Huang, C Zhou, Y Zhang, S Zhang, P Zhang. DBHP-Functionalized ZnO Nanoparticles with Improved Antioxidant Properties as Lubricant Additives. Langmuir. 35, 12, 4342–4352. (2019).

- L Kara, HG Asl, Ö Karadayi. Accepted Manuscript Surface Review and Letters. Surface Review and Letters. (2019).

- L Qin, H Sun, M Hafezi, Y Zhang. Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility. Materials. 12, 18, 3014. (2019).

- LR Hayden, et al. A Comparison of Friction Measurements of Intact Articular Cartilage in Contact with Cartilage, Glass, and Metal. Journal of Biomimetics, Biomaterials and Biomedical Engineering. 41. (2019).

- L Tang, J Kang, P He, S Ding, S Chen, M Liu, et al. Effects of spraying conditions on the microstructure and properties of NiCrBSi coatings prepared by internal rotating plasma spraying. Surface and Coatings Technology. 374, 625-633. (2019).

- L Tiainen, et al. Novel laser surface texturing for improved primary stability of titanium implants. Journal of the Mechanical Behavior of Biomedical Materials. 98, 26-39. (2019).

- L Wang, B Shi, E Hu, K Hu, X Hu. Reuse of spent bleaching clay for supporting MoS2 nanoparticles as a lubricating filler in ABS plastics. Tribology International. 131, 415-423. (2019).

- L Wang, J Jin, C Zhu, G Li, X Kuang, K Huang. Effects of HiPIMS pulse-length on plasma discharge and on the properties of WC-DLC coatings. Applied Surface Science. 487, 526-538. (2019).

- L Xu, R Wang, M Gen, L Lu, G Han. Preparation and Properties of Graphene/Nickel Composite Coating Based on Textured Surface of Aluminum Alloy. Materials. 12, 19, 3240. (2019).

- LY Chen, et al. Phase interaction induced texture in a plasma sprayed-remelted NiCrBSi coating during solidification: An electron backscatter diffraction study. Surface and Coatings Technology. 358, 467-480. (2019).

- LY Chen, H Wang, C Zhao, S Lu, ZX Wang, et al. Automatic remelting and enhanced mechanical performance of a plasma sprayed NiCrBSi coating. Surface and Coatings Technology. 369, 31-43 (2019).

- L Zhao, H Yang, C Liu, S Xue, Z Deng, J Li, X Zeng. The Correlation Between Molecular Structure and Tribological Properties of Graphene Oxide with Different Oxidation Degree. Tribology Letters. 67. (2019).

- M Bai, et al. In-situ Ti-6Al-4V/TiC composites synthesized by reactive spark plasma sintering: processing, microstructure, and dry sliding wear behaviour. Wear. 432–433, 202944. (2019).

- M Chalkiopoulos. Computational and experimental evaluation of performance of thrust bearings operating under TEHD regime. (2019).

- M Dong, M Hafezi, Z Tong, L Qin. Preparation and oil lubrication of polyvinylidene fluoride (PVDF) nanospheres. Materials Research Express. 6, 8. (2019).

- M Gaier. DEVELOPMENT AND CHARACTERIZATION OF HIGH-PERFORMANCE TiC AND TiN CERMETS. DSpace. (2019).

- M Gaier, TZ Todorova, Z Russell, ZN Farhat, et al. The influence of intermetallic ordering on wear and indentation properties of TiC-Ni3Al cermets. Wear. 426–427, Part A, 390-400. (2019).

- M Gaier, ZN Farhat, KP Plucknett. The effects of graphene nano-platelet additions on the sliding wear of TiC-Ni3Al cermets. Tribology International. 130, 119-132. (2019).

- M Klaassen, EG de Vries, MA Masen. Friction in the contact between skin and a soft counter material: Effects of hardness and surface finish. Journal of the Mechanical Behavior of Biomedical Materials. 92, 137-143. 2019).

- M Kocabaş, C Örnek, M Curioni, N Cansever. Nickel fluoride as a surface activation agent for electroless nickel coating of anodized AA1050 aluminum alloy. Surface and Coatings Technology. 364, 231-238. (2019).

- M MacLean. Development and Characterization of Electroless Ni-P Composite Coatings with Superelastic nano-NiTi Additions. DSpace. (2019).

- MM Costa, et al. Tribological behavior of bioactive multi-material structures targeting orthopedic applications. Journal of the Mechanical Behavior of Biomedical Materials. 94, 193-200. (2019).

- M Neto. Understanding the wear and tribocorrosion processes and mechanisms of titanium alloys in bovine serum solution. Materials Science and Engineering. (2019).

- M Peruzzo, et al. Reciprocating sliding wear of the sintered 316L stainless steel with boron additions. Wear. 422–423, 108-118. (2019).

- M Prieske, et al. Friction and wear performance of different carbon coatings for use in dry aluminium forming processes. Surface and Coatings Technology. 357, 1048-1059. (2019).

- MR Mphahlele, et al. Effect of TiN Nanoparticles on the Friction and Wear Properties of Spark Plasma Sintered Fe-Cr-Ni. Tribology in Industry . 41 2, 143-155. 13. (2019).

- M Seloanyane. Tribology of drill bit material in deep oil drilling process: variation of weight on bit (WOB) and bit rotating speed. WIReDSpace. (2019).

- M Shen, Z Zhang, J Yang, G Xiong. Wetting Behavior and Tribological Properties of Polymer Brushes on Laser-Textured Surface. Polymers. 11, 6, 981. (2019).

- M Tahir, AS Mohammed, UA Muhammad. Evaluation of Friction and Wear Behavior of Date Palm Fruit Syrup as an Environmentally Friendly Lubricant. Materials. 12, 10, 1589 (2019).

- MU Azam, BA Ahmed, AS Hakeem, HM Irshad, et al. Tribological behaviour of alumina-based nanocomposites reinforced with uncoated and Ni-coated cubic boron nitride. Journal of Materials Research and Technology. 8, 6, 5066-5079. (2019).

- M Yang, Z Jia, X Pang, X Shao, J Zhen, et al. The Synthesis and Tribological Properties of Carbonized Polydopamine/Ag Composite Films. Journal of Materials Engineering and Performance. 28, 7213–7226. (2019).

- M Zhang, X Liu, H Shang, J Lin. Comparison of TiN and CNx coatings on orthodontic stainless steel: Tribological and biological evaluation. Surface and Coatings Technology. 362, 381-387. (2019).

- N Cameron. Fabrication, Characterization, and Investigation into the Wear Behavior of NiTi-based Nanolaminate Coatings. Shape Memory and Superelasticity. 5, 327–335. (2019).

- N Drahorad. Quantification of tribological effects in expansion fasteners. (2019).

- N Gajić, Ž Kamberović, et al. Synthesis of Tribological WS2 Powder from WO3 Prepared by Ultrasonic Spray Pyrolysis (USP). Metals. 9, 3, 277. (2019).

- N Muthunilavan, et al. Self-repairing effect of few Si3N4 balls used as rolling elements to enhance the performance of bearings operating under contaminated lubrication conditions. Tribology International. 134, 281-295. (2019).

- N Rivera, et al. Ionic-liquid lubrication of a nickel-based coating reinforced with tungsten carbide particles. Journal of Molecular Liquids. 293, 111498. (2019).

- N Rivera, et al. Tribological behavior of three fatty acid ionic liquids in the lubrication of different material pairs. Journal of Molecular Liquids. 296, 111858. (2019).

- N Rivera, et al. Tribological performance of three fatty acid anion-based ionic liquids (FAILs) used as lubricant additive. Journal of Molecular Liquids. 296 111811 (2019).

- N Ur Rahman, DTA Matthews, et al. An Overview: Laser-Based Additive Manufacturing for High Temperature Tribology. Front. Mech. Eng. 5, 16. (2019).

- O Çomaklı, et al. Effect of gas mixture on tribological performance of plasma nitrided grey cast iron under dry and lubricated conditions. Materials Research Express. (2019).

- O Çomakli, et al. Tribological and electrochemical behavior of Ag2O/ZnO/NiO nanocomposite coating on commercial pure titanium for biomedical applications. 71, 10,. 1166-1176. (2019).

- O Mysiukiewicz, et al. Frictional Properties of α-Nucleated Polypropylene-Based Composites Filled with Wood Flour. International Scientific-Technical Conference MANUFACTURING. 461-472. (2019).

- O Poliarus, et al. Effect of Powder Preparation on the Microstructure and Wear of Plasma-Sprayed NiAl/CrB2 Composite Coatings. Journal of Thermal Spray Technology. 28, 1039–1048. (2019).

- P Čípek, D Rebenda, et al. Visualization of Lubrication Film in Model of Synovial Joint. Tribology in Industry. 41, 3, 387-393. (2019).

- P Turtoi, MD Pascovici, T Cicone. Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams. Lubricants. 7, 10, 86. (2019).

- Q Fang, F Ye, X Yang. Influence of hydrolysis of polyvinyl alcohol on its lubrication for styrene-ethylene-butylene-styrene block copolymer. Tribology International. 134, 408-416. (2019).

- Q Feng, W Li, X Liu, W Ji, Z Zhou. Investigation of reciprocating friction characteristics between different bionic surfaces of prosthesis materials and skin. Biosurface and Biotribology. 5, 2, 57-66, 6. (2019).

- Q Gao, et al. Laser cladding Ti-Ni/TiN/TiW+TiS/WS2 self-lubricating wear resistant composite coating on Ti-6Al-4V alloy. Optics & Laser Technology. 113, 182-191. (2019).

- Q Wan, B Yang, HD Liu, J Chen, J Zhang. Microstructure and adhesion of MeN/TiSiN (Me = Ti, Cr, Zr, Mo, NbxAl1−x) multilayered coatings deposited by cathodic arc ion plating. Applied Surface Science. 497, 143602. (2019).

- Q Ye, et al. Grafting Robust Thick Zwitterionic Polymer Brushes via Subsurface-Initiated Ring-Opening Metathesis Polymerization for Antimicrobial and Anti-Biofouling. ACS Appl. Mater. Interfaces. 11, 42, 39171–39178. (2019).

- R An, M Wu, J Li, X Qiu, FU Shah, J Li. On the ionic liquid films ‘pinned’ by core–shell structured Fe3O4@carbon nanoparticles and their tribological properties. Physical Chemistry Chemical Physics. (2019).

- RED Rudge, E Scholten, JA Dijksman. Advances and challenges in soft tribology with applications to foods. Current Opinion in Food Science. 27, 90-97. (2019).

- R González, JL Viesca, et al. Two phosphonium cation-based ionic liquids as lubricant additive to a polyalphaolefin base oil. Journal of Molecular Liquids. 293, 111536. (2019).

- RO Ferreira, GB Galvani, IS Tertuliano, et al. Characterization and evolution of the coefficient of friction during pin on disc tribotest: Comparison between C10200 Cu, AA6082-T6 Al and C36000 brass pins under varying normal loads. Tribology International. 138, 403-414. (2019).

- R Rattan, J Bijwe. Role of Orientation of Graphite Fabric in Polyetherimide Composite with Respect to Loading Direction on the Wear Performance in Various Wear Modes. Tribology Letters. 67, 36. (2019).

- R Śledzik, et al. Frictional Properties of a-Nucleated Polypropylene-Based Composites Filled with Wood Flour. Advances in Manufacturing II: Volume 4. (2019).

- SA Wohaibi, et al. Tribological Characterization of Micron-/Nano-Sized WC-9%Co Cemented Carbides Prepared by Spark Plasma Sintering at Elevated Temperatures. Materials. 12, 6, 920. (2019).

- SH Duntu, I Ahmad, M Islam, S Boakye-Yiadom. Effect of graphene and zirconia on microstructure and tribological behaviour of alumina matrix nanocomposites. Wear. 438–439, 203067. (2019).

- S Hu, et al. Self-Compensating Liquid-Repellent Surfaces with Stratified Morphology. ACS Appl. Mater. Interfaces. 12, 3, 4174–4182. (2019).

- S He, L Yu, H Ju, Y Geng, I Asempah, J Xu. Influence of V content on properties of Ti–W–V–N films. Surface Engineering. 35, 1. (2019).

- S Huang, A He, JH Yun, et al. Synergistic tribological performance of a water based lubricant using graphene oxide and alumina hybrid nanoparticles as additives. Tribology International. 135, 170-180. (2019).

- SH van der Poel, M Mezera, GRBE Römer, EG de Vries, et al. Fabricating Laser-Induced Periodic Surface Structures on Medical Grade Cobalt–Chrome–Molybdenum: Tribological, Wetting and Leaching Properties. Lubricants. 7, 8, 70. (2019).

- S Jitphayomkun, et al. Investigation on the tribological characteristics of lubricated Al<sub>2</sub>O<sub>3</sub>-TiC (AlTiC) surface. Journal of Metals, Material, and Minerals. 29, 1. (2019).

- SK Singh, et al. Electrodeposited SiC-graphene oxide composite in nickel matrix for improved tribological applications. Surface Topography: Metrology and Properties. 7, 3. (2019).

- S Madeira, M Buciumeanu, O Carvalho, FS Silva. Influence of sintering pressure on the microstructure and tribological properties of low temperature fast sintered hot-pressed Y-TZP. Ceramics International. 45, 5, 5883-5893. (2019).

- SMM de Oliveira, et al. Comparative Study of Candida albicans Inactivation by Nonthermal Plasma on Stainless Steel with and without Diamond-like Carbon Film. ACS Omega. 4, 4, 6891–6902. (2019).

- S Nie, F Lou, H Ji, F Yin. Tribological Performance of CF-PEEK Sliding against 17-4PH Stainless Steel with Various Cermet Coatings for Water Hydraulic Piston Pump Application. Coatings. 9, 7, 436. (2019).

- S Nie, W Xu, F Yin, H Ji, Y Xu, Z Hu, et al. Investigation of the tribological behaviour of cermets sliding against Si3N4 for seawater hydraulic components applications. Surface Topography: Metrology and Properties. 7, 4. (2019).

- S Ploypech, et al. Effects of Crack Density on Wettability and Mechanical Properties of Hard Chrome Coatings. Transactions of the Indian Institute of Metals. 72, 929–934. (2019).

- S Ren, L Lv, J Ma, H Lu, J Guo, X Li, et al. Slow-release lubrication effect of graphene oxide/poly(ethylene glycol) wrapped in chitosan/sodium glycerophosphate hydrogel applied on artificial joints. Materials Science and Engineering: C. 98, 452-460. (2019).

- S Rung, et al. Possibilities of Dry and Lubricated Friction Modification Enabled by Different Ultrashort Laser-Based Surface Structuring Methods. Lubricants. 9, 7, 5, 43. (2019).

- S Samanta, S Singh, RR Sahoo. Covalently grafting of self-assembled functionalized graphene oxide multilayer films on Si substrate for solid film lubrication. Thin Solid Films. 683, 16-26. (2019).

- S Samanta, S Singh, RR Sahoo. Lubrication of dry sliding metallic contacts by chemically prepared functionalized graphitic nanoparticles. Friction. 8, 708–725. (2019).

- S Sardar, SK Karmakar, D Das. Microstructure and Tribological Performance of Alumina–Aluminum Matrix Composites Manufactured by Enhanced Stir Casting Method. J. Tribol. 141, 4: 041602-041624. (2019).

- S Sharma, J Bijwe, S Panier. Exploration of potential of Zylon and Aramid fibers to enhance the abrasive wear performance of polymers. Wear. 422–423, 180-190. (2019).

- S Singh, S Samanta, AK Das, RR Sahoo. Hydrophobic Reduced Graphene Oxide-Based Ni Coating for Improved Tribological Application. Journal of Materials Engineering and Performance. 28, 3704–3713. (2019).

- ST Pham, et al. Oxidative and Frictional Behavior of a Binary Sodium Borate–Silicate Composite in High-Temperature Lubricant Applications. Ind. Eng. Chem. Res. 59, 7, 2921–2933. (2019).

- S Zhang, Y Qiao, Y Liu, L Ma, J Luo. Molecular behaviors in thin film lubrication—Part one: Film formation for different polarities of molecules. Friction. 7, 372–387. (2019).

- S Zhou, W Li, W Zhao, C Liu, Z Fang, X Gao. Tribological behaviors of polyimide composite films enhanced with fluorographene. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 580, 123707. (2019).

- T Bao, Z Wang, Y Zhao, Y Wang, X Yi. Long-term stably dispersed functionalized graphene oxide as an oil additive. RSC Adv. 9, 39230-39241. (2019).

- T Han, et al. Contribution of a Tribo-Induced Silica Layer to Macroscale Superlubricity of Hydrated Ions. J. Phys. Chem. 123, 33, 20270–20277. (2019).

- T MacLucas, S Suarez. On the Solid Lubricity of Electrophoretically Deposited Carbon Nanohorn Coatings. Lubricants. 7, 8, 62. (2019).

- T Mishra, et al. The effects of contact configuration and coating morphology on the tribological behaviour of tetrahedral amorphous diamond-like carbon (ta-C DLC) coatings under boundary lubrication. 13, 2, 120-129. (2019).

- Tomáš Hudec, et al. Structure, mechanical and tribological properties of Mo-S-N solid lubricant coatings. Applied Surface Science. 486, 1-14. (2019).

- VP Parikh, A Ahmadi, MH Parekh, et al. Upcycling of Spent Lithium Cobalt Oxide Cathodes from Discarded Lithium-Ion Batteries as Solid Lubricant Additive. Environ. Sci. Technol. 53, 7, 3757–3763. (2019).

- WJ Hu, Z Zhang, X Zeng, JS Li. Correlation between the Degree of Alkylation and Tribological Properties of Amino-PEG2-amine-Based Organic Friction Modifiers. Ind. Eng. Chem. Res. 59, 1, 215–225. (2019).

- W Jia, J Tian, P Bai, S Li, H Zeng, W Zhang, et al. A novel comb-typed poly(oligo(ethylene glycol) methylether acrylate) as an excellent aqueous lubricant. Journal of Colloid and Interface Science. 539, 342-350. (2019).

- WJ Lee, J Kim, HW Park. Improved corrosion resistance of Mg alloy AZ31B induced by selective evaporation of Mg using large pulsed electron beam irradiation. Journal of Materials Science & Technology. 35, 5, 891-901. (2019).

- W Li, et al. Tribological behaviors of CrN/Cr3C2-NiCr duplex coating at elevated temperatures. Surface and Coatings Technology. 378, 124926. (2019).

- W Liu, et al. Green oil additive g-C3N4: a feasible strategy to enhance the tribological properties of DLC film. Materials Research Express. 6, 11. (2019).

- W Liu, H Wang, Y Liu, J Li, A Erdemir, J Luo. Mechanism of Superlubricity Conversion with Polyalkylene Glycol Aqueous Solutions. Langmuir. 35, 36, 11784–11790. (2019).

- W Ouyang, Z Xu, S Jia, M Zhang, Y Ye, et al. Multilayer-graphene reinforced 316L matrix composites preparation by laser deposited additive manufacturing: microstructure and mechanical property analysis. Materials Research Express, 6, 9. (2019).

- W Song, B Jiang, D Ji. Improving the Tribological Performance of MAO Coatings by Using a Stable Sol Electrolyte Mixed with Cellulose Additive. Materials. 12, 24, 4226. (2019).

- W Wang, H Zhou, Q Wang, J Jin, Y Sun, K Wang. High-Temperature Tribological Behavior of the Ti-22Al-25Nb (at. %) Orthorhombic Alloy with Lamellar O Microstructures. Metals. 9, 1, 5. (2019).

- W Zhao, W Zhao, Z Huang, G Liu, B Wu. Tribological performances of epoxy resin composite coatings using hexagonal boron nitride and cubic boron nitride nanoparticles as additives. Chemical Physics Letters. 732, 136646. (2019).

- X Ci, et al. Revealing the lubrication mechanism of fluorographene nanosheets enhanced GTL-8 based nanolubricant oil. Tribology International. 138, 174-183. (2019).

- X Ge, J Li, C Zhang, Y Liu, J Luo. Superlubricity and Antiwear Properties of In Situ-Formed Ionic Liquids at Ceramic Interfaces Induced by Tribochemical Reactions. ACS Appl. Mater. Interfaces. 11, 6, 6568–6574. (2019).

- X Ge, J Li, H Wang, C Zhang, Y Liu, J Luo. Macroscale superlubricity under extreme pressure enabled by the combination of graphene-oxide nanosheets with ionic liquid. Carbon. 151, 76-83. (2019).

- X Ge, T Halmans, J Li, J Luo. Molecular behaviors in thin film lubrication—Part three: Superlubricity attained by polar and nonpolar molecules. Friction. 7, 625–636. (2019).

- X Han, et al. Tribological performance of oil‐based ZnO and diamond nanofluids. Lubrication Science. 31, 3, 73-84. (2019).

- X Jiang, D Zhao, Y Wang, W Duan, L Wang. Toward hard yet tough VC coating via modulating compressive stress and nanostructure to enhance its protective performance in seawater. Ceramics International. 45, 1, 1049-1057. (2019).

- X Ji, X Li, Y Dong, R Sammons, L Tian, H Yu, et al. Synthesis and in-vitro antibacterial properties of a functionally graded Ag impregnated composite surface. Materials Science and Engineering: C. 99, 150-158. (2019).

- X Li, J Deng, Y Lu, L Zhang, J Sun, F Wu. Tribological behavior of ZrO2/WS2 coating surfaces with biomimetic shark-skin structure. Ceramics International. 45, 17, part A, 21759-21767. (2019).

- X Li, S Huang, Y Wu, H Huang. Performance evaluation of graphene oxide nanosheet water coolants in the grinding of semiconductor substrates. Precision Engineering. 60, 291-298. (2019).

- X Lv, L Cao, Y Wan, T Xu. Effect of different electrolytes in micro-arc oxidation on corrosion and tribological performance of 7075 aluminum alloy. Materials Research Express. 6, 8. (2019).

- X Su, D Hao, Z Li, X Guo, L Jiang. Design of hierarchical comb hydrophilic polymer brush (HCHPB) surfaces inspired by fish mucus for anti-biofouling. Journal of Materials Chemistry B. 8. (2019).

- • X Wang, C Wang, X Shen, F Sun. Tribological behaviors of the diamond films sliding against the T800/X850 CFRP laminates. Wear. 418–419, 191-200. (2019).

- X Wang, et al. Properties of GO/WC–Co coatings prepared via different pulverisation processes. Surface Engeneering. 35, 11, 933-946. (2019).

- X Wu, W Li, K Chen, D Zhang, L Xu, X Yang. A tough PVA/HA/COL composite hydrogel with simple process and excellent mechanical properties. Materials Today Communications. 21, 100702. (2019).

- X Wu, Y Xie, C Xue, K Chen, X Yang, L Xu, et al. Preparation of PVA-GO composite hydrogel and effect of ionic coordination on its propertie. Materials Research Express, 6, 7. (2019).

- •X Xu, F Su, Z Li. Tribological properties of nanostructured TiAlN/W2N multilayer coating produced by PVD. Wear. 430–431, 67-75. (2019).

- X Yang, D Zhang, G Liu, J Wang, Z Luo, X Peng, et al. Bioinspired from mussel and salivary acquired pellicle: a universal dual-functional polypeptide coating for implant materials. Materials Today Chemistry. 14, 100205. (2019).

- X Zhou, C Ouyang. Wear and Corrosive Behaviors of Electroless Ni-LaCl3 Composites on Nanoporous ATO Surface of Ti Substrate. Journal of Materials Engineering and Performance. 28, 2499–2512. (2019).

- Y Gao, et al. Cholesterol ester derivatives as oil-based lubricant additives: mesogenic and tribological properties. Materials Research Express. 6, 12. (2019).

- Y Gao, Y Jiang, W Hu, H Jiang, J Li. Cholesteryl liquid crystals as oil-based lubricant additives: Effect of mesogenic phases and structures on tribological characteristics. Langmuir. 35, 21, 6981–6992. (2019).

- Y Guo, J Guan, H Peng, X Shu, L Chen, H Guo. Tightly adhered silk fibroin coatings on Ti6Al4V biometals for improved wettability and compatible mechanical properties. Materials & Design. 175, 107825. (2019).

- Y Han, S Liu, Y Sun, Y Gu, H Zhang. Bioinspired Surface Functionalization of Titanium for Enhanced Lubrication and Sustained Drug Release. Langmuir, 35, 20, 6735–6741. (2019).

- Y Hu, Y Wang, et al. One-pot pyrolysis preparation of carbon dots as eco-friendly nanoadditives of water-based lubricants. Carbon. 152, 511-520. (2019).

- Y Hu, Y Wang, Z Zeng, et al. BLG-RGO: A novel nanoadditive for water-based lubricant. Tribology International. 135, 277-286. (2019).

- Y Li, H Lu, Q Liu, L Qin, G Dong. A facile method to enhance the tribological performances of MoSe2 nanoparticles as oil additives. Tribology International. 137, 22-29. (2019).

- Y Li, SZ Zhang, JX Qiu, YY He, JJ Xiu, QW Ye, et al. Effect of Electric Potentials on Microstructure, Corrosion and Wear Characteristic of the Nitrided Layer Prepared on 2Cr13 Stainless Steel by Plasma Nitriding. Acta Metallurgica Sinica.32, 733–745. (2019).

- Y Li, Q Ye, Y Zhu, L Zhang, Y He, S Zhang, et al. Microstructure, adhesion and tribological properties of CrN/CrTiAlSiN/WCrTiAlN multilayer coatings deposited on nitrocarburized AISI 4140 steel. Surface and Coatings Technology. 362, 27-34. (2019).

- Y Liu, J Li, X Chen, J Luo. Fluorinated Graphene: A Promising Macroscale Solid Lubricant under Various Environments. ACS Appl. Mater. Interfaces. 11, 43, 40470–40480. (2019).

- Y Liu, X Chen, J Li, J Luo. Enhancement of friction performance enabled by a synergetic effect between graphene oxide and molybdenum disulfide. Carbon. 154, 266-276. (2019).

- Y Meng, F Su, Z Li. Boundary and Elastohydrodynamic Lubrication Behaviors of Nano-CuO/Reduced Graphene Oxide Nanocomposite as an Efficient Oil-Based Additive. Langmuir. 35, 32, 10322–10333. (2019).

- Y Ni, X Li, G Dong, Z Tong, et al. The combined effect of La and heat treatment on the tribological performances of tin-Babbitt alloy. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 233, 7. (2019).

- Y Tao, F Ma, M Teng, Z Jia, Z Zeng. Designed fabrication of super high hardness Ni-B-Sc nanocomposite coating for anti-wear application. Applied Surface Science. 492, 426-434. (2019).

- Y Tsujii, et al. Lubricant and srt material. Kyoto University Yokohama National University NUC. (2019).

- Y Tsujii, et al. Srt material, composite and method for producing the same. US Patent App. 16. (2019).

- Y Uzun, H Kovacı, AF Yetim, A Çelik. Effect of boronizing on the structural, mechanical and tribological properties of CoCrW dental alloy produced by selective laser melting. Industrial Lubrication and Tribology. 71, 3, 348-356. (2019).

- Y Yang, C Zhang, Y Dai, J Luo. Lubricity and Adsorption of Castor Oil Sulfated Sodium Salt Emulsion Solution on Titanium Alloy. Tribology Letters. 67. (2019).

- Y Wang, D Cao, W Gao, Y Qiao, Y Jin, G Cheng, et al. Microstructure and properties of sol-enhanced Co-P-TiO2 nano-composite coatings. Journal of Alloys and Compounds. 792, 617-625. (2019).

- Y Wang, et al. The performances of modified single-walled carbon nanotubes/poly(ether ether ketone) composites prepared by solution blending and melt blending. High Performance Polymers. (2019).

- Y Wang, Y Du, J Deng, Z Wang. Friction reduction of water based lubricant with highly dispersed functional MoS2 nanosheets. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 562, 321-328. (2019).

- Y Xu, RL Jackson, Y Chen, A Zhang. (2019). Nanoscale Measurements of the Real Area of Contact and Comparison to Theoretical Models. IEEE Holm Conference on Electrical Contacts. 1-8. (2019).

- Y Yan, et al. Euryale Ferox Seed‐Inspired Superlubricated Nanoparticles for Treatment of Osteoarthritis. Advanced Functional Materials. 29, 4, 1807559. (2019).

- Y Yao, Y Xu, X Fan, M Zhu, G Liu. Tribological properties of spherical and mesoporous NiAl particles as ionic liquid additives. Friction. 8, 384–395. (2019).

- Y Ye, H Chen, S Guo, S Sun, Y Wang, H Zhao, et al. Comparison of WC/C nanocomposite films in load-bearing capacity via interface micro-cracks during tribology behavior: A feasible judgment mechanism. Ceramics International. 45, 17, Part B, 23482-23492. (2019).

- Y Zhang, L Zeng, Z Wu, X Ding, K Chen. Synergy of surface textures on a hydraulic cylinder piston. Materials Science and Engineering. 14, 4, 424 – 429. (2019).

- Y Zhao, K Feng, C Yao, P Nie, J Huang, Z Li. Microstructure and tribological properties of laser cladded self-lubricating nickel-base composite coatings containing nano-Cu and h-BN solid lubricants. Surface and Coatings Technology. 359, 485-494. (2019).

- Y Zhao, M Zou. Experimental investigation of the wear mechanisms of thin PDA/PTFE coatings. Progress in Organic Coatings. 137, 105341. (2019).

- Y Zhou, J Peng, M Wang, J Mo, C Deng, M Zhu. Tribochemical Behavior of Pure Magnesium During Sliding Friction. Metals. 9, 3, 311. (2019).

- Z Ahmed Baduruthamal, et al. Tribological and Electrochemical Characterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications. Materials. 12, 22, 3665. (2019).

- Z Cai, Z Li, Y Ding, J Zheng, J Liu, Z Zhou. Preparation and impact resistance performance of bionic sandwich structure inspired from beetle forewing. Composites Part B: Engineering. 161, 490-501. (2019).

- Z Chen, H Yan, P Zhang, Z Yu, Q Lu, J Guo. Microstructural evolution and wear behaviors of laser-clad Stellite 6/NbC/h-BN self-lubricating coatings. Surface and Coatings Technology. 372, 218-228. (2019).