Brake Materials Screening

Achieve Cost-Effective Development of Friction Materials

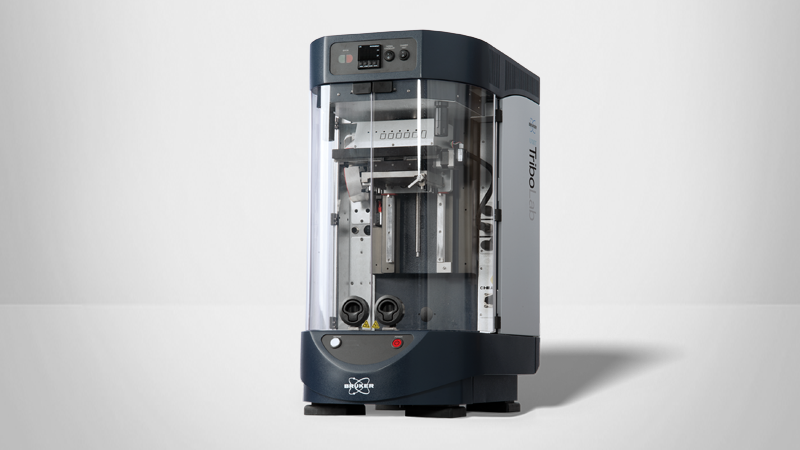

Bruker's UMT TriboLab™ Brake Material Screening Tester performs benchtop testing using small samples, applying the comparable contact pressures used in a full-scale dynamometer rig.

The flexibility and range of testing capabilities of the Brake Material Screening solution rapidly and cost-effectively allows users to rank materials using protocols based on industry standards such as the SAE J2522 (AK Master). This ultimately enables the brake material industry to reduce development cycle times.

Speed Up Pad Development

Government environmental regulations and the industry demand for improved braking systems continue to drive the need for development of new formulations for brake pad materials.

While multiple formulations and process conditions could potentially meet these needs, full-scale dynamometer testing prior to on-road vehicle testing makes new friction material development both time-consuming and expensive.

Sample sizes for Brake Material Screening are considerably smaller, removing the need to construct complete brake pads of a potentially large number of candidate materials. By performing screening tests on small samples, but with comparable dynamometer test pressure, the brake material industry can effectively speed up development by selecting only the top few candidate materials to move forward for complete dynamometer functional testing, saving significant cost.

Correlate with Dynamometer Tests

With Brake Material Screening on the UMT TriboLab, it is now possible to test brake materials in real time and easily program industry-standard dynamometer protocols and standards, all while monitoring key parameters such as friction and temperature.

Perform a Comprehensive Suite of Tests

The Brake Material Screening solution simulates a wide range of different modes:

- Constant deceleration test mode

- Constant velocity (drag) test mode

- Brake material COF as a function of velocity, temperature, or contact pressure

- Effect of humidity on brake material behavior

- Fade and recovery protocols

Take Advantage of Unique Benefits

The Brake Material Screening capability allows developers to quickly reformulate and test materials to comply with recent regulations and facilitates fundamental research of new pad and rotor materials.

TriboLab Brake Material Screening provides:

- Accurate and repeatable COF and wear measurements on a single system

- Experimental data correlated to industry standards (e.g., SAE J2522)

- Control of speed, pressure, humidity, and temperature

- Creation of flexible test procedures

- Meaningful measurements on samples prepared from real pads and rotors

- Reduced testing time and improved throughput for fast ranking of material formulations

- Lowered environmental impact during test procedures