Formation Evaluation for Operations, Drilling and Completions

Characterize Cuttings On-site with Lab-quality Precision

The mud log has become indispensable since its commercial introduction in 1939, but with minimal change. Though more surface and drilling sensors have been added to digital logs, the geologic description of samples remains central to the process. The mud log could be poised for a rebirth, rising to meet the needs and challenges of a drilling industry after the unconventional revolution. Cuttings offer a source of information that cannot be easily gathered in horizontal wells by wireline logging or measurement while drilling.

Cuttings are a Direct Measurement of the Target Formations

Cuttings provide a valuable direct measurement of rock where physical and chemical properties can be directly assessed. Cuttings provide a cost-effective alternative and supplement to high-resolution chemostratigraphy on core by providing:

- A cost-effective real-time direct measurement of formations

- Data for both horizontal and vertical wells

- Retention of organic matter

- No down-hole operational risk

Near Real-time Elemental Data On-site

On-site elemental data can revolutionize a drilling program. Wellsite X-ray Fluorescence (XRF) analysis programs are easy to implement into any standard mudlogging workflow. Cleaned and dried cuttings can be easily prepared in sample cups or pressed pellets to provide laboratory-quality geochemical analysis in near real-time. This data can be used for:

- Landing a well with confidence by identifying geochemical markers

- Additional information for Geosteering and a backup technology in the event of a MWD or LWD failure

- Identifying downhole lithology with confidence as a verification to wireline and MWD

- Identifying metal in cuttings to determine if it is from the bit, casing, whip stock or surface equipment

- Building local or regional chemostratigraphy models that provide more accurate correlations between wells

- Providing additional information for fracture design

- Improving future well planning

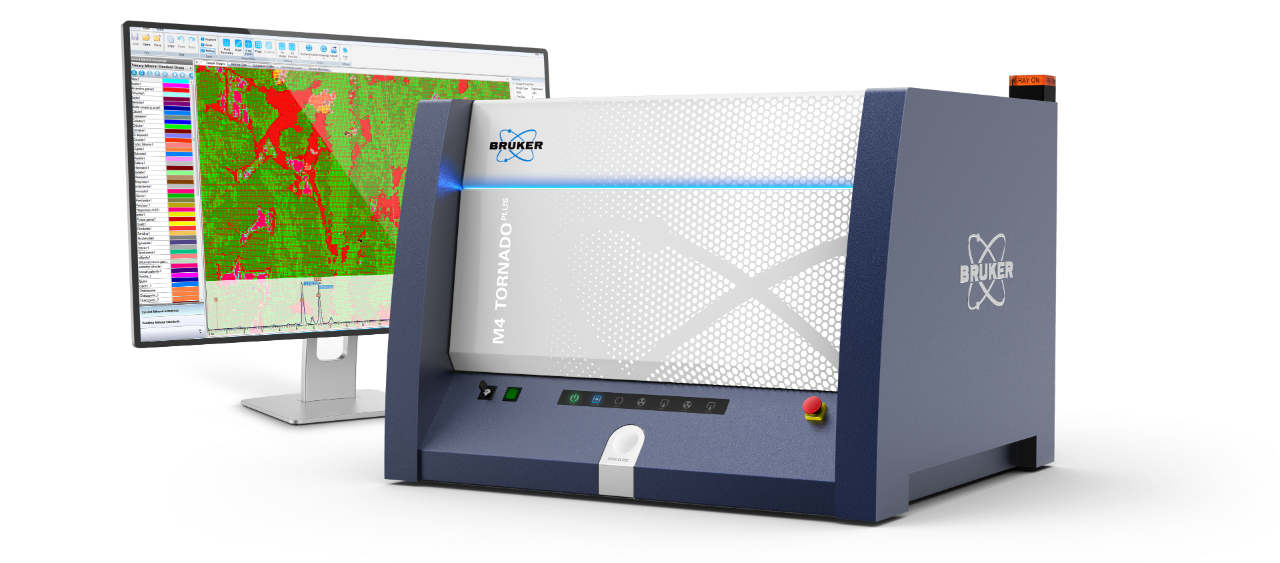

Mineral Data On-site for Better Decisions

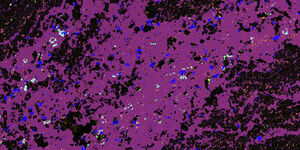

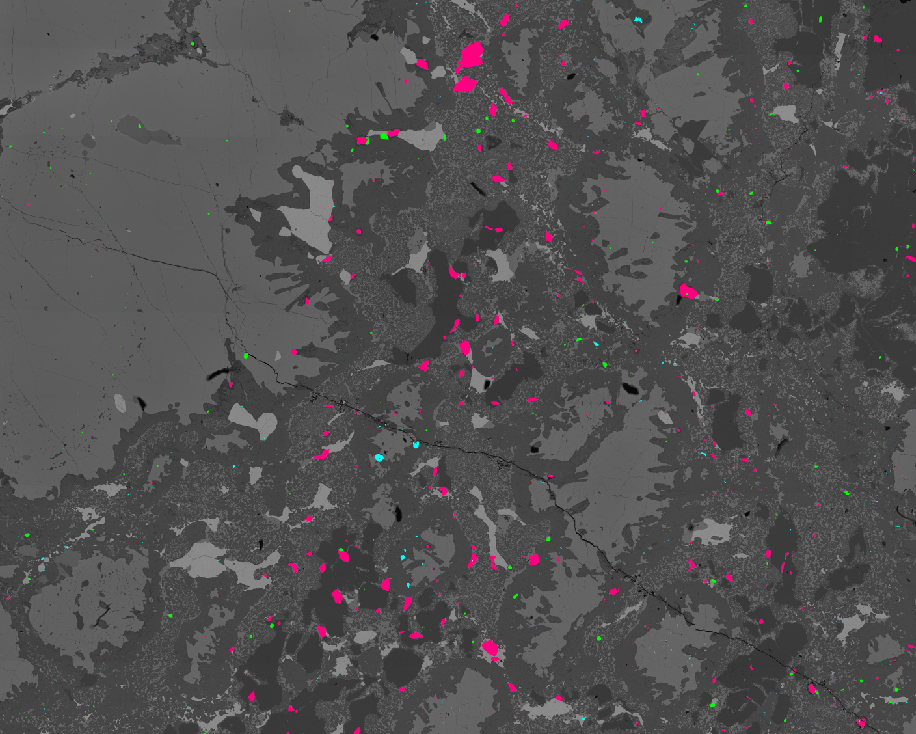

Mineral data at the well-site has been sought-after to aid in formation evaluation, completions design and to de-risk wells. It has been well established that poor stage performance has been linked to properties like rock type and pre-existing fractures. The addition of on-site mineral identification can give operations geologists and petroleum engineers near real-time data for robust scientific decision making that reduces costs and increases performance. For example, Bruker's automated mineralogy solution AMICS leverages technologies that can be deployed on-site or in forward field labs to collect mineral data from cuttings. All Bruker’s solutions are easy to set up, can be run by a technician with remote data reduction, and run off standard rig power.

Lithofacies Characterization and Formation Evaluation with Mineral and Elemental Data

Elemental and mineral data is most useful as part of a comprehensive formation evaluation program. Well-site mineral and geochemical data can be incorporated into reservoir and petroleum system models as tools for all aspects of the exploration and development process. For example:

- Bulk and modal mineral information can be incorporated into reservoir quality assessments and the identification of problematic zones (e.g. swelling clays)

- Textural analysis and lithotyping can divide the formation into lithofacies that are easy to understand and incorporated into completions design and well planning

- Aid in sequence stratigraphic interpolations and well-to-well correlations

- Provenance analysis including identification and mapping of datable minerals

- Compute rock geomechanical and physical properties including Young’s modulus, wettability, hardness

- Direct analysis of porosity, compaction, kerogen, texture, grain size, grain shape, grain composition and diagenesis

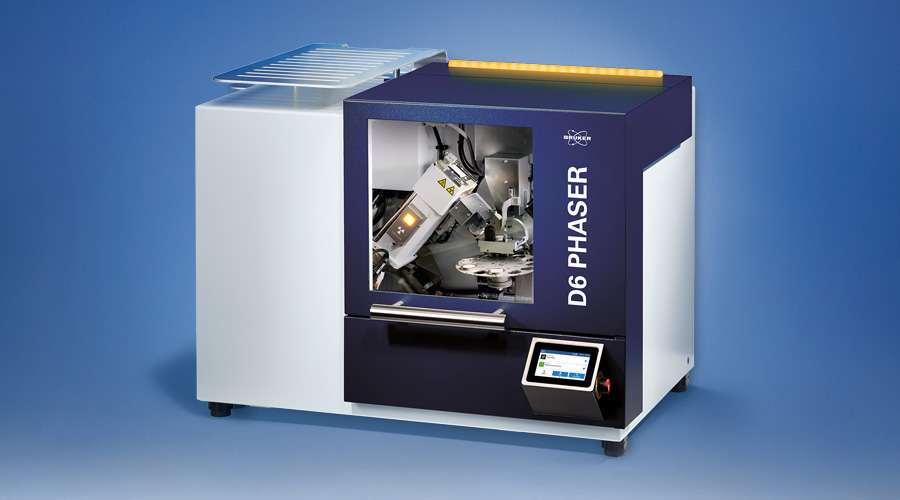

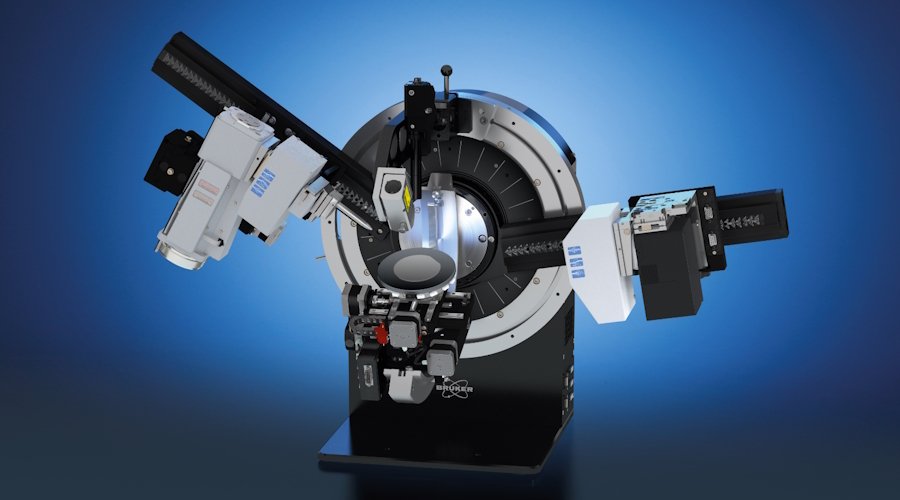

Identification of Swelling Clays with the D6 PHASER

Clay minerals comprise a large class of fine-grained, layered silicates that result from the weathering of bulk minerals. Clays are of particular interest for the mining and drilling industries due to the physical properties they impart on surrounding geological formations. Here, we discuss the qualitative analysis of clays by X-ray diffraction (XRD) with the D6 PHASER benchtop diffractometer, specifically towards identifying swelling clay species. Clay minerals are a key concern in many drilling applications. For example, in the hydraulic fracturing industry, high concentrations of clays indicate higher ductility and can lead to poor fracture formation. Additionally, the presence of swelling clays can lead to water-induced swelling during the initiation process or negative effects, such as self-healing, during production stages. The identification of these minerals is essential for developing tailored solutions for additives and stabilizers.