Revealing the Relation Between Microstructural Heterogeneities and Local Mechanical Properties of Complex-Phase Steel by Correlative Electron Microscopy and Nanoindentation Characterization

Materials and Design 203 (2021) 109620

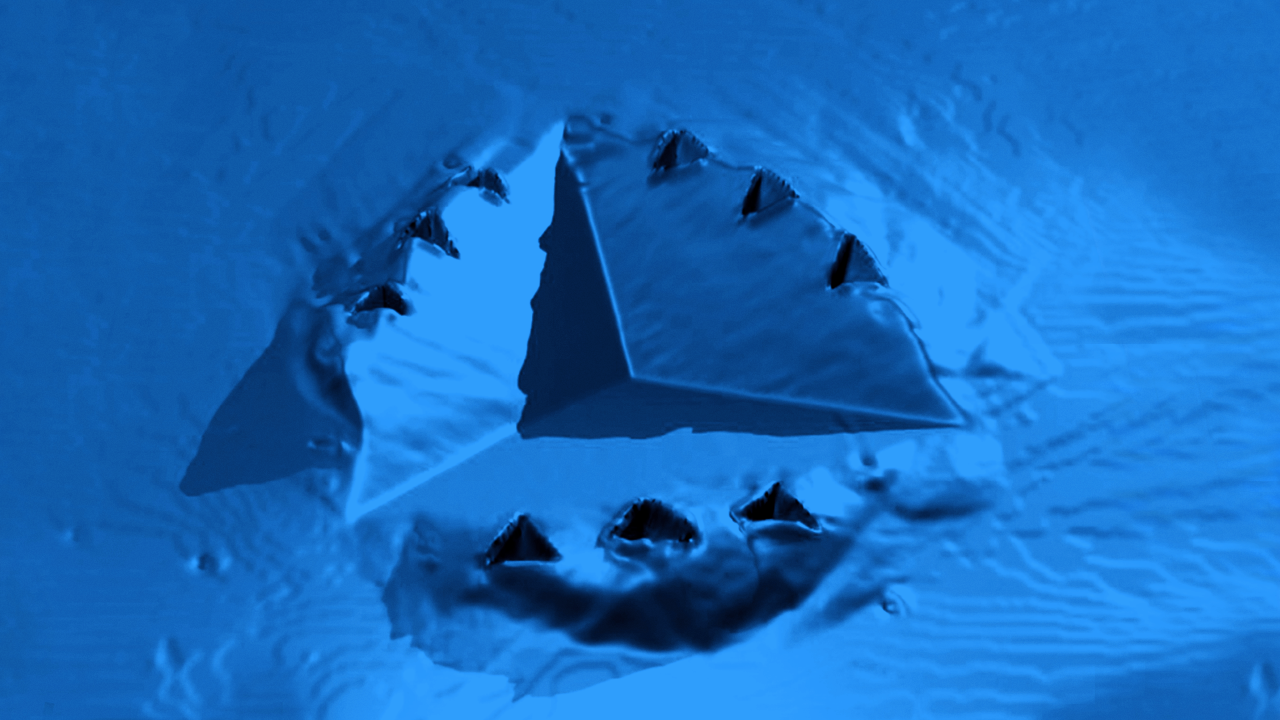

In this Materials and Design article, the authors characterize the compositional and microstructural heterogeneity of a commercial complex-phase steel (CP800) by combining various electron microscopy techniques and nanoindentation. They use Bruker's XPM (accelerated property mapping) mode to obtain high-resolution hardness maps. A cube-corner indenter and micro-newton load were applied to limit the indent depth and spacing between adjacent indents to the nanometer scale. The resulting high-resolution hardness map is obtained and successfully overlapped with EPMA and EBSD results, based on which the correlation between compositional heterogeneity and hardness variation in complex-phase microstructure can successfully established.

In materials science the measured mechanical properties and the materials microstructure are closely linked. EPMA and EBSD are allowing insights into the local chemical composition and materials texture with evermore increased spatial resolution and have given an indication that the local properties of CP800 will be varying.

For the first time, a hardness map quantifies these local changes at highest resolution and demonstrates the close link between local chemistry, dislocation density, grain orientation of matrix, and precipitates the development of mechanical properties in adjacent grains or phases at the sub-µm level.