Tobacco

Analysis of Tobacco

Bruker helps you to focus on continuous improvement for highest productivity and superior product quality, from assessing the purchased tobacco quality to testing the final blends. In order to manufacture consistent quality of the tobacco products, it is essential to gain instant feedback of chemical composition from materials, processing intermediates and products.

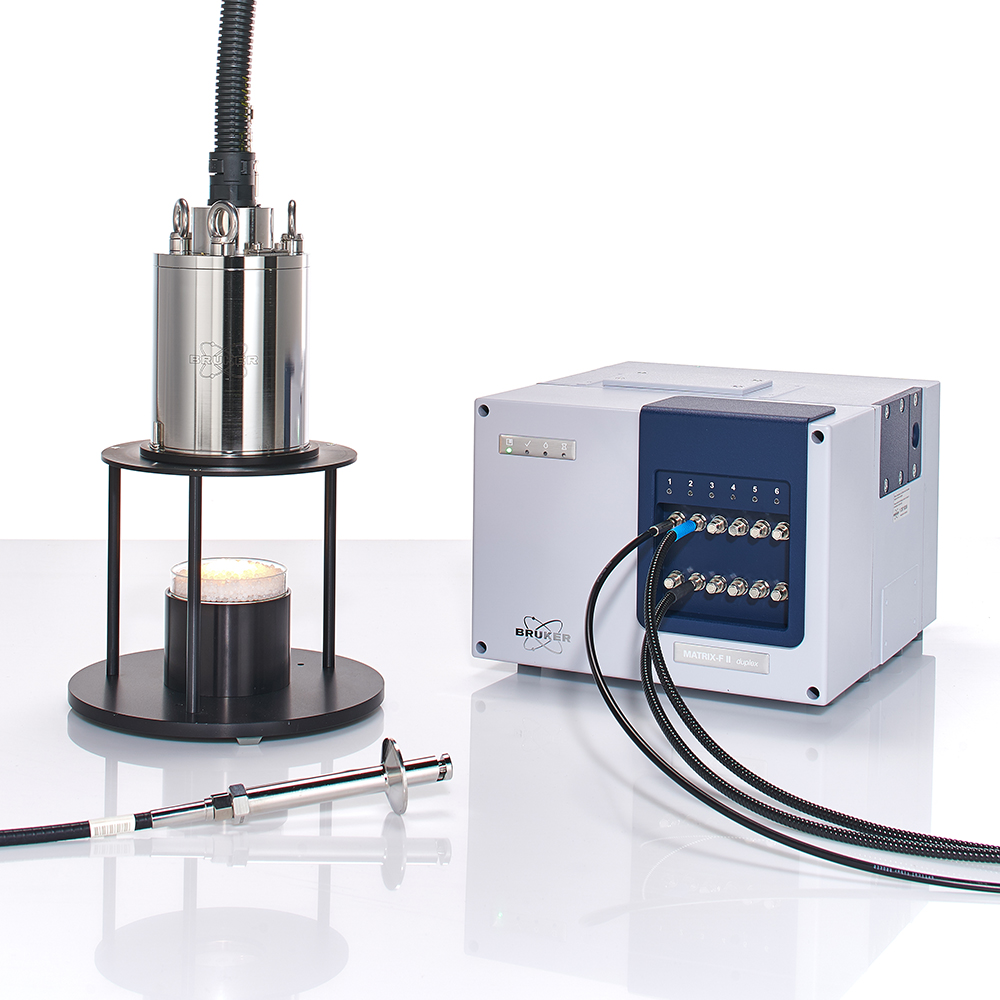

FT-NIR spectroscopy has been used for a long time in the tobacco factories for the analysis of incoming tobacco leaves as well as for monitoring the production process. Classical applications include the analysis of moisture, nicotine content, chlorine, total sugar as well as reducing sugar. A complete analysis takes less than 30 seconds and can be applied in the laboratory as well as on-line, e.g. for the process verification of tobacco blends.

XRF is a fast, nondestructive technology for heavy metal screening of final tobacco products as well as of the varying soils and media used in the grow. Bruker’s Elemental Analyzer portfolio includes high-throughput lab-based ED-XRF and WD-XRF, point-and-shoot handheld XRF, micro-XRF, and ultra-trace analysis TXRF spectrometers.