Limestone and Gypsum Mining

Analytical tools for exploration and production of limestone and gypsum

Calcium Carbonate (CaCO3), Gypsum (CaS04) and related minerals are the most common sources of calcium, an element used extensively in industrial processes, foods, and building materials. Target rocks for calcium-bearing minerals are extensive and include limestone, dolomite, marl, and chalk. Cement production facilities and other users of calcium and gypsum require high-purity product. Bruker’s analysis tools empower mines to grade their products and certify its quality.

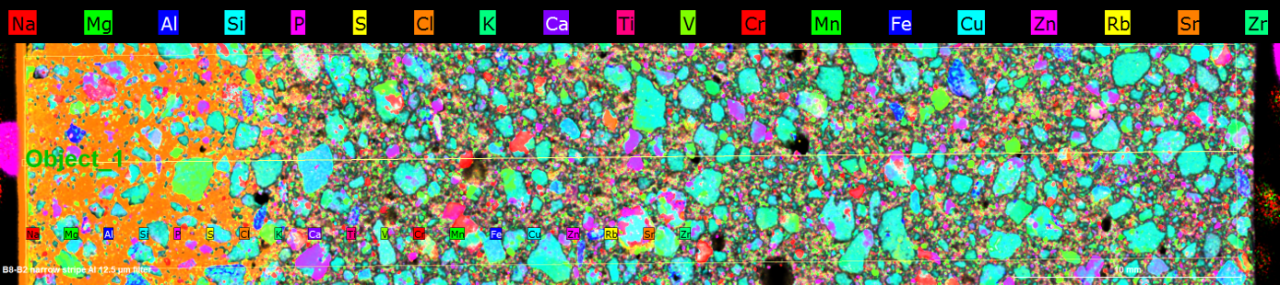

Purity analysis and grade control with X-ray fluorescence

Purity criteria, which is critical for grade control focuses on calcium (Ca), magnesium (Mg), silicon (Si), aluminum (Al), iron (Fe), and potassium (K). X-ray fluorescence spectroscopy (XRF) is the most efficient and effective way to conduct purity analysis and grade limestone.

Portable and handheld energy dispersive XRF provide on-site instantaneous results for mine operations, exploration, core scanning, and excavation planning. The Bruker pXRF Limestone and Gypsum Calibration is a matrix-matched calibration specifically designed for purity analysis.

Benchtop energy dispersive XRF enables high-throughput sample analysis with either a XY autochanger or a carousel sample changer. Optional vacuum chamber enables the best performance for light elements on an ED-XRF.

Benchtop or free standing WD-XRF instruments provide the lowest detection limits and most accuracy for select elements.

Explore XRF Options

| S1 TITAN 800 | Portable XRF | Portability and power define the S1 TITAN, with a rugged case, Titan Detector Shield™ and GeoExploration calibration. Portable XRF is ideal for on-site analysis, exploration, and core scanning. |

| CTX | Countertop XRF | The CTX is a rugged and portable single-sample countertop XRF with battery backup, safety interlocked lid, Titan Detector Shield™ and push-button operation that is ideal for quick-look grade control and process control. |

| S2 PUMA | Benchtop ED-XRF | The S2 PUMA Series 2 is the standard for laboratory ED-XRF analysis, equipped with the intuitive TouchControl™ interface and XY robotic multi-sample or carousel sample changer. |

| S6 JAGUAR | Benchtop Sequential WD-XRF | The S6 JAGUAR provides WD-XRF performance in a compact package ideal for any laboratory analysis. |

| S8 TIGER | Sequential WD-XRF | The S8 TIGER Series 2 sequential WDXRF provides outstanding superior analytical performance for the most demanding mineral and mining applications. |

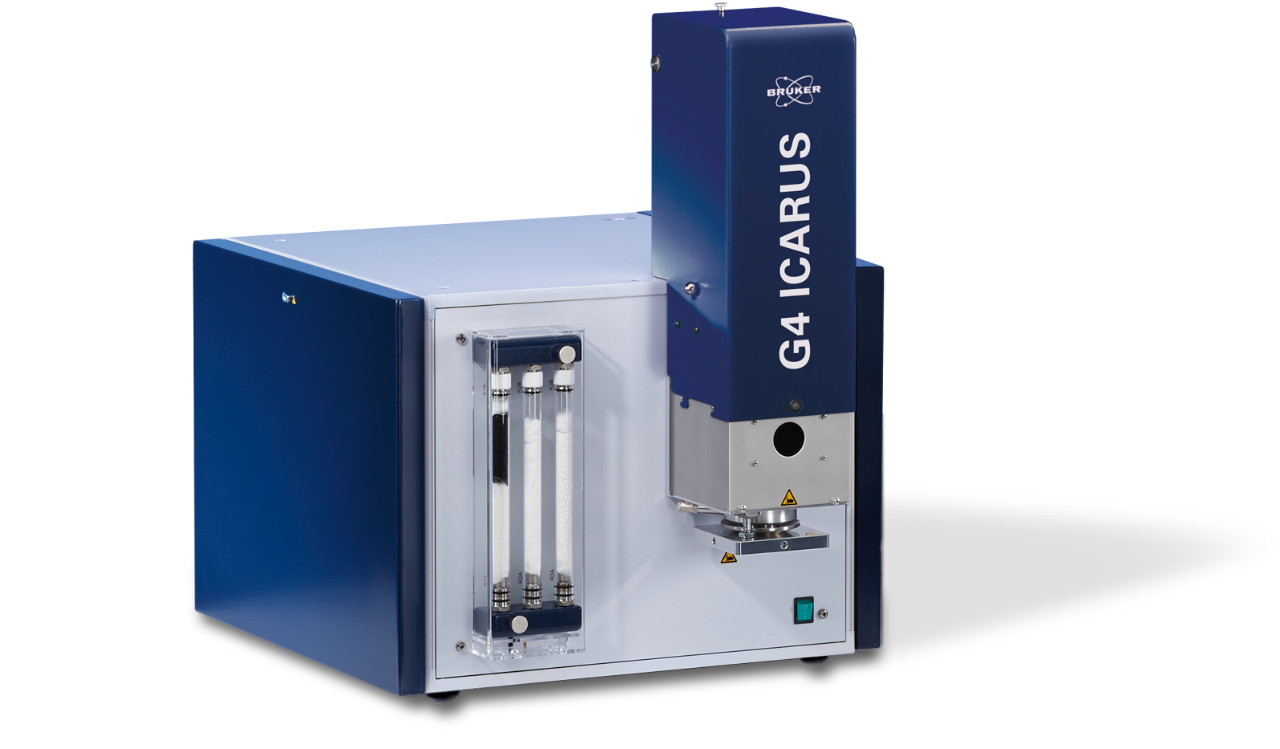

Carbon and Sulfur by Combustion with the G4 ICARUS

Carbon and sulfur analysis by combustion provides critical information on the physical properties of limestone and dolomite and are some of the most important measures for quality control of limestone ores. One of the most effective means for measuring C and S are with a SC combustion analyzer like the G4 ICARUS Series 2. In this CS combustion analyzer sulfur is oxidized to SO2 and carbon to CO2. The G4 ICARUS Series 2 is robust and easy to use, delivering fast and accurate carbon and sulfur results from the quarry to the cement kiln.

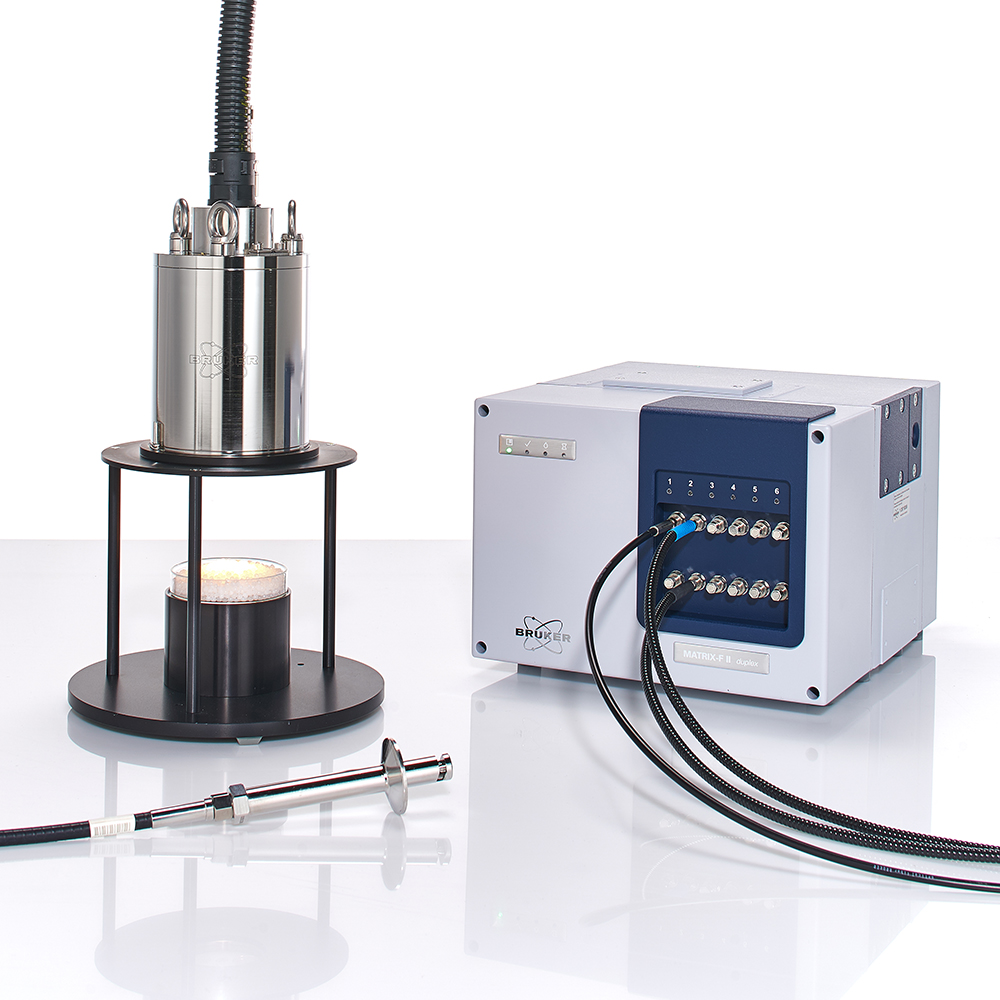

Once of the most common uses for limestone is in the production of cement. Bruker has closely partnered with the cement industry to develop unique solutions and focus on the strong integration of XRF, XRD, and FT-IT tools. Click below to explore Bruker’s solutions for the entire cement value chain.