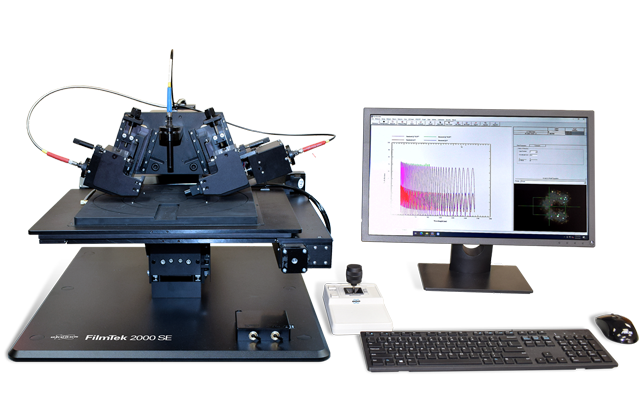

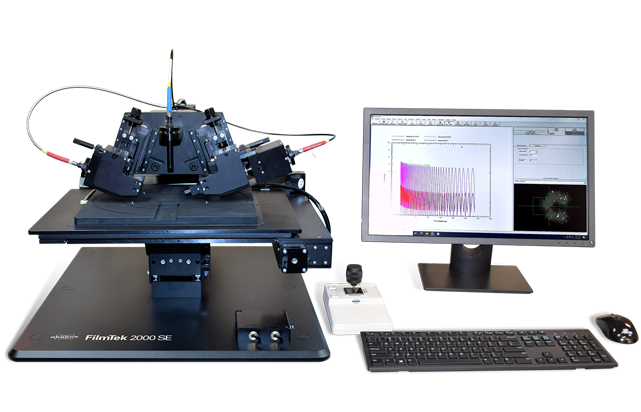

FilmTek 2000 SE

FilmTek 2000 SE

The FilmTek™ 2000 SE is a benchtop spectroscopic ellipsometer with an automated stage that can accommodate 300mm wafers, allowing for uniformity measurements of thin films. Utilizing an advanced rotating compensator design, the 2000 SE delivers unmatched measurement performance and speed for thin film applications. Our film modeling software and in-house dispersion formula allow for easy data processing, giving accurate and precise real-time results.

Measurement Capabilities

Enables simultaneous determination of:

- Multiple layer thicknesses

- Indices of refraction [ n(λ) ]

- Extinction (absorption) coefficients [ k(λ) ]

- Energy band gap [ Eg ]

- Composition (e.g., %Ge in SiGex, % Ga in GaxIn1-xAs, %Al in AlxGa1-xAs, etc.)

- Surface roughness

- Constituent, void fraction

- Crystallinity/Amorphization (e.g., of Poly-Si or GeSbTe films)

- Film gradient

System Components

Standard:

- Spectroscopic ellipsometry with rotating compensator design (300nm-1700nm)

- Multi-angle, polarized spectroscopic reflection (240nm-1700nm)

- Measures film thickness and index of refraction independently

- Automated stage with autofocus

- Ideal for measuring ultra-thin films (0.03 Å repeatability on native oxide)

- Advanced material modeling software

- Bruker's generalized material model with advanced global optimization algorithms

Optional:

- Generalized ellipsometry (4×4 matrix generalization method) for anisotropy measurements (nx, ny, nz)

Typical Application Areas

Virtually all translucent films ranging in thickness from less than 1 Å to approximately 150 µm can be measured with high precision.

Flexible hardware and software can be easily modified to satisfy unique customer requirements, particularly in academic and R&D environments.

Typical application areas include:

- Semiconductor and dielectric materials

- LED/OLED

- Multilayer optical coatings

- Optical antireflection coatings

- Electro-optical materials

- Computer disks

- Coated glass

- Thin metals

- Solar cells

Technical Specifications

| Film Thickness Range | 0 Å to 150 µm |

|---|---|

| Film Thickness Accuracy | ±1.0 Å for NIST traceable standard oxide 100 Å to 1 µm |

| Spectral Range | 240 nm - 1700 nm (240 nm - 1000 nm is standard) |

| Measurement Spot Size | 3 mm |

| Sample Size | 2 mm - 300 mm (150 mm standard) |

| Spectral Resolution | 0.3 nm - 2nm |

| Light Source | Regulated deuterium-halogen lamp (2,000 hrs lifetime) |

| Detector Type | 2048 pixel Sony linear CCD array / 512 pixel cooled Hamamatsu InGaAs CCD array (NIR) |

| Automated Stage with Auto Focus | 300 mm (200 mm is standard) |

| Computer | Multi-core processor with Windows™ 10 Operating System |

| Measurement Time | ~2 sec per site (e.g., oxide film) |

Performance Specifications

| Film(s) | Thickness | Measured Parameters | Precision (1σ) |

|---|---|---|---|

| Oxide / Si | 0 - 1000 Å | t | 0.03 Å |

| 1000 - 500,000 Å | t | 0.005% | |

| 1000 Å | t , n | 0.2 Å / 0.0001 | |

| 15,000 Å | t , n | 0.5 Å / 0.0001 | |

| 150.000 Å | t , n | 1.5 Å / 0.00001 | |

| Nitride / Si | 200 - 10,000 Å | t | 0.02% |

| 500 - 10,000 Å | t , n | 0.05% / 0.0005 | |

| Photoresist / Si | 200 - 10,000 Å | t | 0.02% |

| 500 - 10,000 Å | t , n | 0.05% / 0.0002 | |

| Polysilicon / Oxide / Si | 200 - 10,000 Å | t Poly , t Oxide | 0.2 Å / 0.1 Å |

| 500 - 10,000 Å | t Poly , t Oxide | 0.2 Å / 0.0005 |

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.