Quantitative AFM Nanomechanics Data for Machine Learning and Materials Development

AFM-based nanomechanical measurements and machine learning provides new insights into the mechanical properties of polymeric materials.

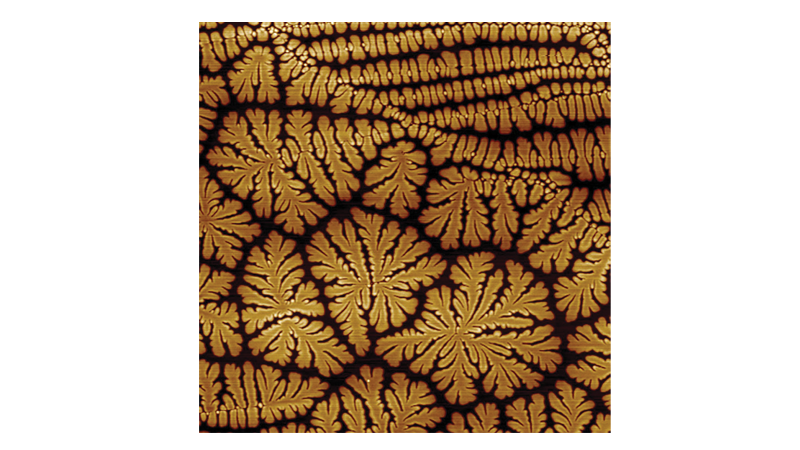

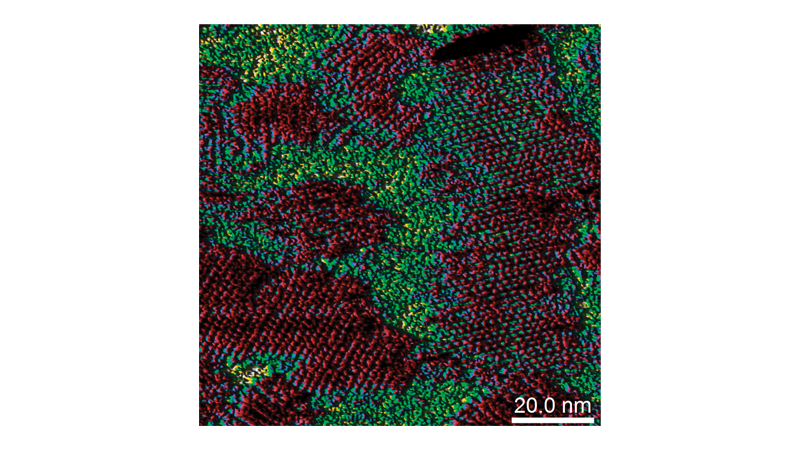

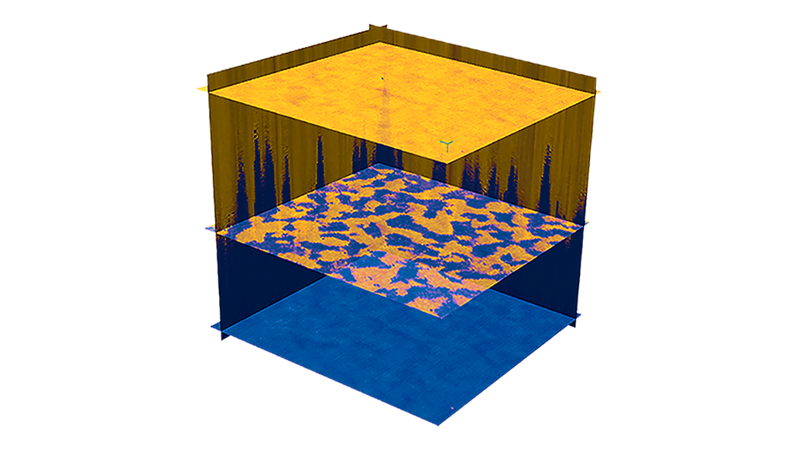

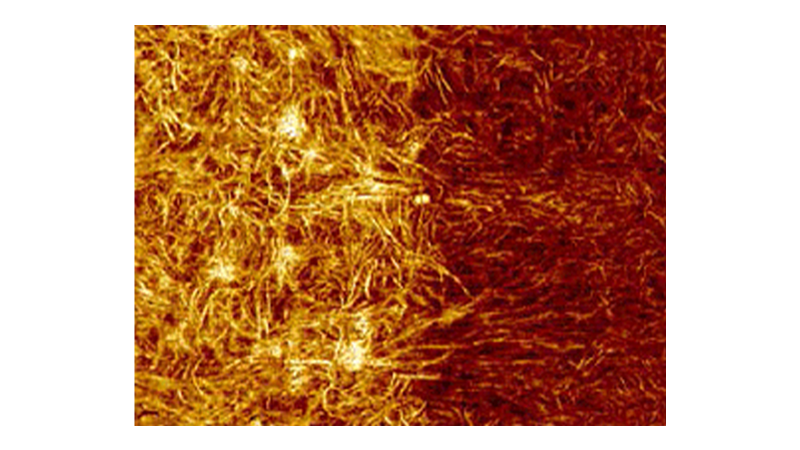

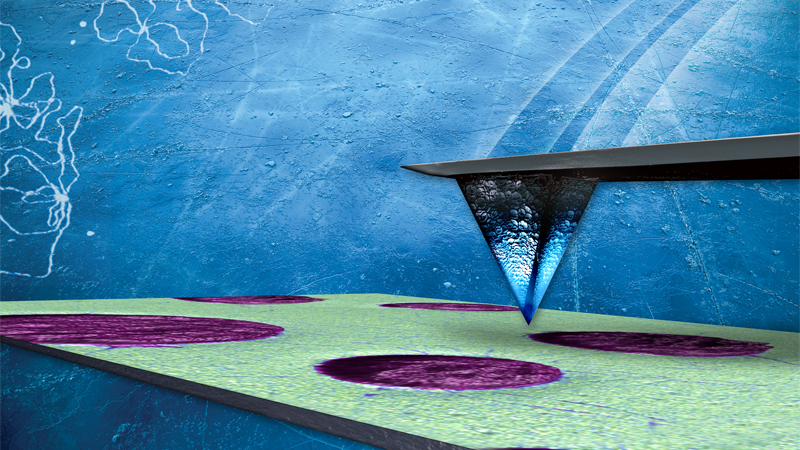

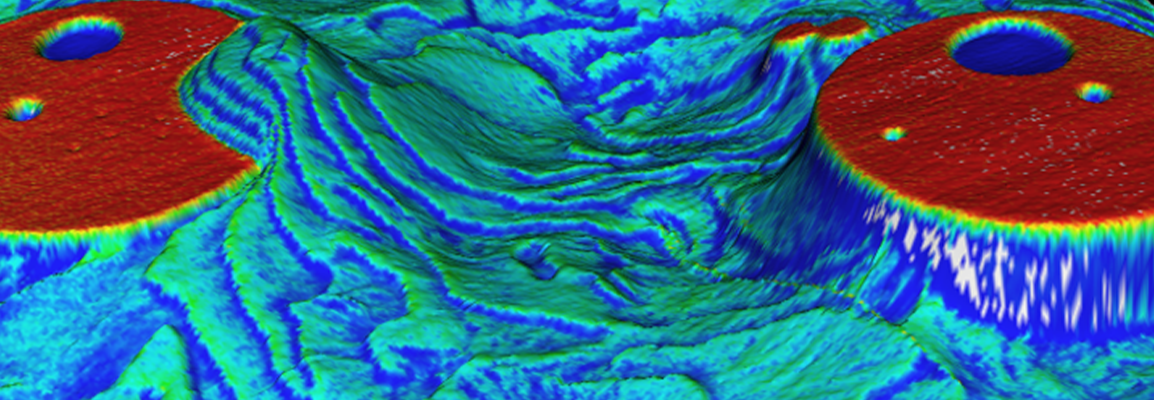

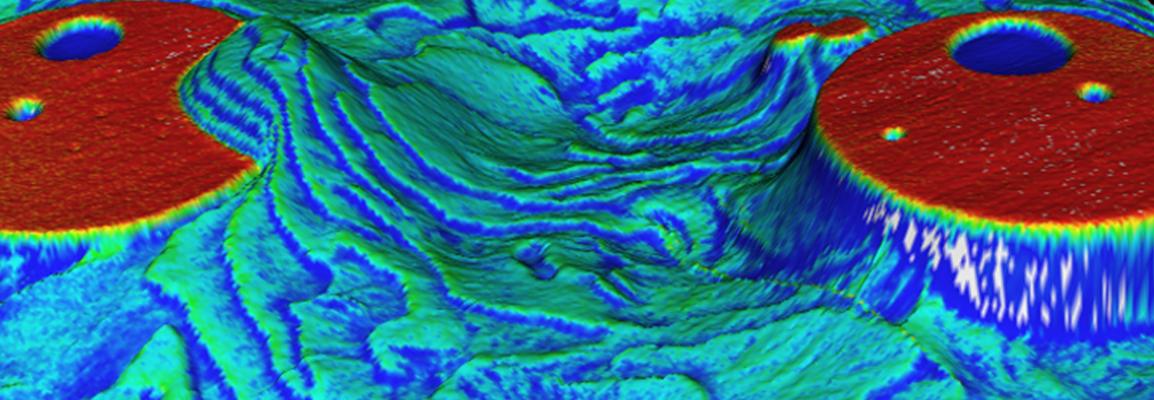

In this webinar, presenters demonstrate how to use AFM data to apply machine learning to materials development, also introducing AFM modes used in automated polymer R&D — including Tapping Mode, PeakForce Tapping, datacube, PeakForce-QNM and AFM-nDMA.

Webinar Summary

For material development, it is of interest to understand the relationship between microstructure and properties at the macroscale. In this webinar, the presenters highlight how AFM-based nanomechanical measurements and machine learning can provide new insights into the mechanical properties of polymeric materials.

The first part of this webinar is dedicated to the following goals:

- Demonstrate how AFM is ideally suited for providing the data needed to apply machine learning (ML) to materials development due to its ability to provide quantitative maps of mechanical properties at the nanoscale.

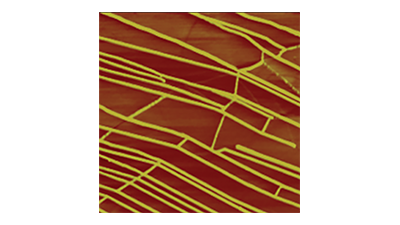

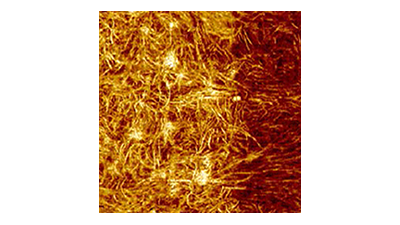

- Introduce several AFM modes that are commonly used in polymer research and describe their advantages and challenges.

- Discuss methods to automate and maximize the speed of acquisition, optimize property map accuracy, and take advantage of novel property channels and multidimensional data cubes.

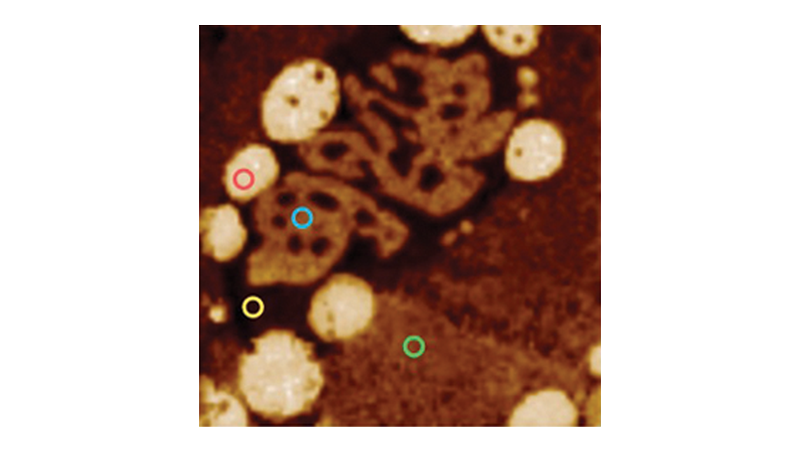

In the second part, the presenters discuss computational methods and ML algorithms dealing with data clustering (such as K-Means or Automatic Gaussian Mixture Model) that can be used to detect the different domains and (inter)phases in materials (e.g. polymer blends, hydrogels, nanocomposites, block copolymers, etc.) by partitioning the recorded data into clusters according to similarities. Additionally, based on the Tabor coefficient calculation, the presenters also propose some protocols that can be easily implemented to rapidly determine which mechanical model(s) can be applied to obtain quantitative mapping of the mechanical properties for each local domain or phase.

This algorithmically driven approach enables AFM users to analyze materials with more complex architectures and/or other properties, opening new avenues of research for advanced materials with specific functions and desired properties leading to the creation of functional and more reliable structural materials.

This webinar was presented on March 16, 2021.

Find out more about the technology featured in this webinar or our other solutions for AFM:

Speakers

Bede Pittenger, Ph.D., Sr. Staff Development Scientist, AFM Applications, Bruker Nano Surfaces

Dr. Bede Pittenger is a Senior Staff Development Scientist in the AFM Unit of Bruker's Nano Surfaces Business. He received his PhD in Physics from the University of Washington (Seattle, WA) in 2000, but has worked with scanning probe microscopes for 25 years, building systems, developing techniques, and studying properties of materials at the nanoscale. His work includes more than thirty publications and three patents on various techniques and applications of scanning probe microscopy. Dr. Pittenger's interests span topics from interfacial melting of ice, to mechanobiology of cells and tissues, to the nanomechanics of polymers and composites.

Prof. Dr. Philippe LECLERE

Associate Professor, University of Mons

Philippe Leclère, Ph.D. is a Research Director of the Belgian National Fund for Scientific Research (FRS – FNRS) and associate professor at UMONS. His research interests include characterization of the morphology, electrical and mechanical properties of polymeric systems such as blends, nanocomposites, block copolymers, liquid crystals, and supramolecular (nano)structures. These systems find applications in organic electronics and energy harvesting devices (field effect transistors, organic light emitting diodes, (hybrid) photovoltaic solar cells, batteries, nanogenerators and (bio)sensors), in smart coatings as well as biomimetic polymer-based materials. In addition, Philippe has been active in development and validation of novel SPM techniques and methodologies to quantitatively determine mechanical, thermal, electrical and the “coupled” properties (such as piezoelectricity, flexoelectricity and thermoelectricity) of polymeric and hybrid materials at the nanoscale. He is author of about 200 papers (h-index of 42) in the field and gave more than 300 talks around the world. He is currently the President of NanoWal (the Wallonia Network for Nanotechnologies) and Vice-President of the Royal Belgian Society for Microscopy.