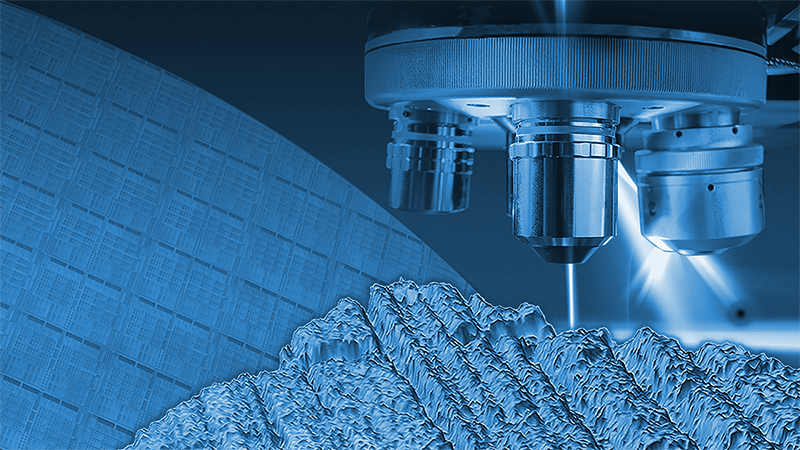

Using Optical Profiling to Optimize Finishing Steps in Additive Manufacturing

In contemporary manufacturing, controlling key process parameters and accurately performing necessary finishing steps is critical to minimizing defect risks and meeting requirements.

This webinar focuses on the processes and best practices for using optical profiling to enhance the efficacy of advanced manufacturing and 3D printing processes (ranging from bed fusion of metallic powder to polymer-printing surfaces), the shininess/appearance of parts, and end-product quality.

Presented by Bruker applications expert Samuel Lesko, Ph.D., and geared toward the interests of material development researchers, additive and 3D printing manufacturing engineers, quality control engineers, metrology engineers, and finishing process designers.

Interested in controlling the quality of the finishing steps for your additive-manufactured or 3D-printed parts?

Surface Texture Metrology for New and Evolving Manufacturing Processes

Viewers can expect to learn:

- The underlying parameters and challenges associated with additive and 3D printing technologies;

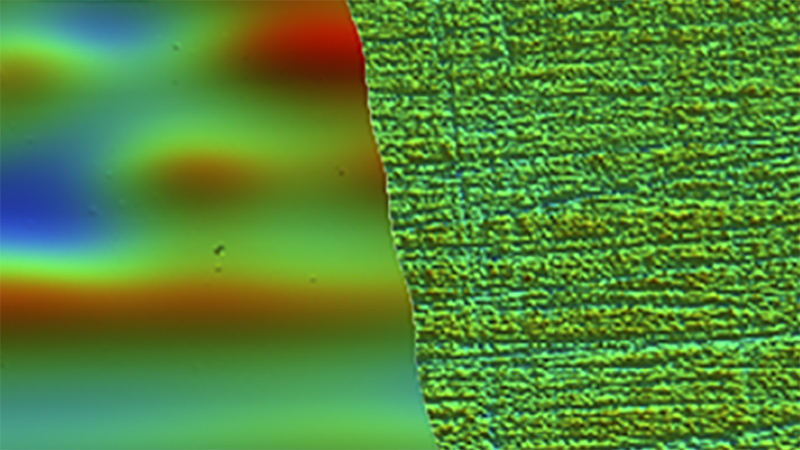

- How to use an optical profiler to collect information on process performance and the product failure;

- Which areal roughness parameters control efficiency of finishing steps and how to improve them;

A Q&A session will close the event.

- The ways that efficient areal roughness parameters within these new manufacturing processes supersede Ra;

- How to identify the appropriate parameters to test and control for unique applications; and

- The steps and methods needed for quality control over a wide range of end-product characteristics, such as aesthetics, shininess, or wear resistance.

Speaker

Samuel Lesko, Ph.D.

Dir. of Technology and Apps Development for Tribology, Stylus & Optical Profilers, Bruker

Samuel Lesko has over 20 years of optical and stylus profiler applications experience, particularly in using white-light interferometry in a wide variety of fields, from MEMS and semiconductor to automotive and aerospace. He is a member of SME and part of ISO/TC 213/WG committee (areal roughness) and obtained his physics Ph.D. and material science engineering degree at the University of Burgundy in France.