Benchtop NMR for

Process Analytical Technology

Highlights

understanding

Bringing a wealth of structural information and direct quantification to your lab, the Fourier PAT benchtop NMR reduces tedious calibrations and increase (bio)process understanding and control, hence further reducing risks and cost. The solution is enabled by the brand-new synTQ by Optimal NMR adapter, welcoming the Bruker Fourier 80 to the world of Process Analytical Technology.

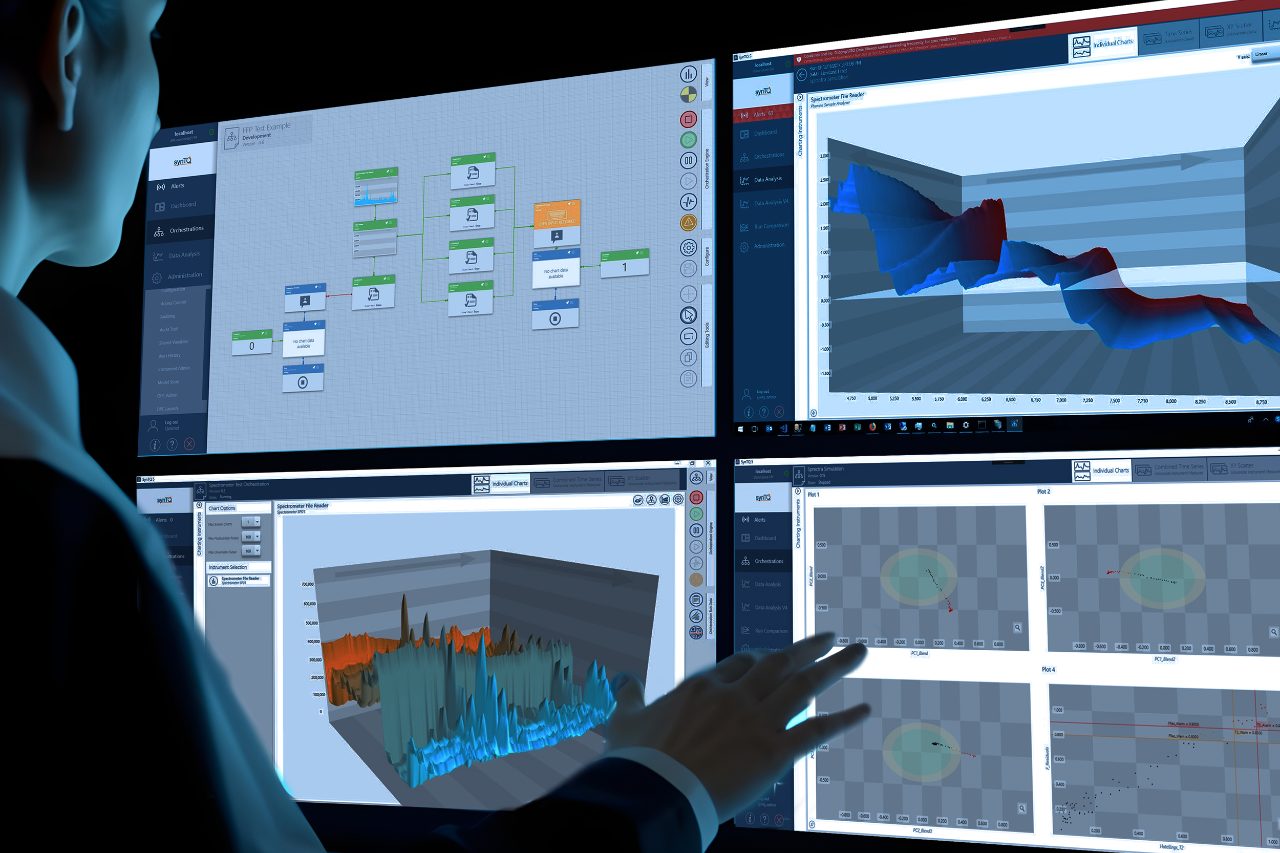

Fourier PAT is the complete solution for online Nuclear Magnetic Resonance (NMR) monitoring and control of your process, with oversight of chemical reactions in real-time under real process conditions. Mastering the art of orchestration and thanks to more than 200 adapters in its portfolio, synTQ has the potential to interact with multiple systems in your lab: starting from your reactor, its sensors, moving to all components of the Fourier RxnLab, other analytical instrumentation (IR, Raman, etc.) and to data processing software… in an infinite loop of process optimization and control to provide a clear, faster, and safer way forward for your research.

The Fourier PAT finds natural applications to batch and flow chemistry processes for pharma, biochemical and chemical applications. It is the ideal solution to be considered in a digital lab/plant scenario and especially for late development and advanced manufacturing modalities like the Production On Demand concept.

Technical Features

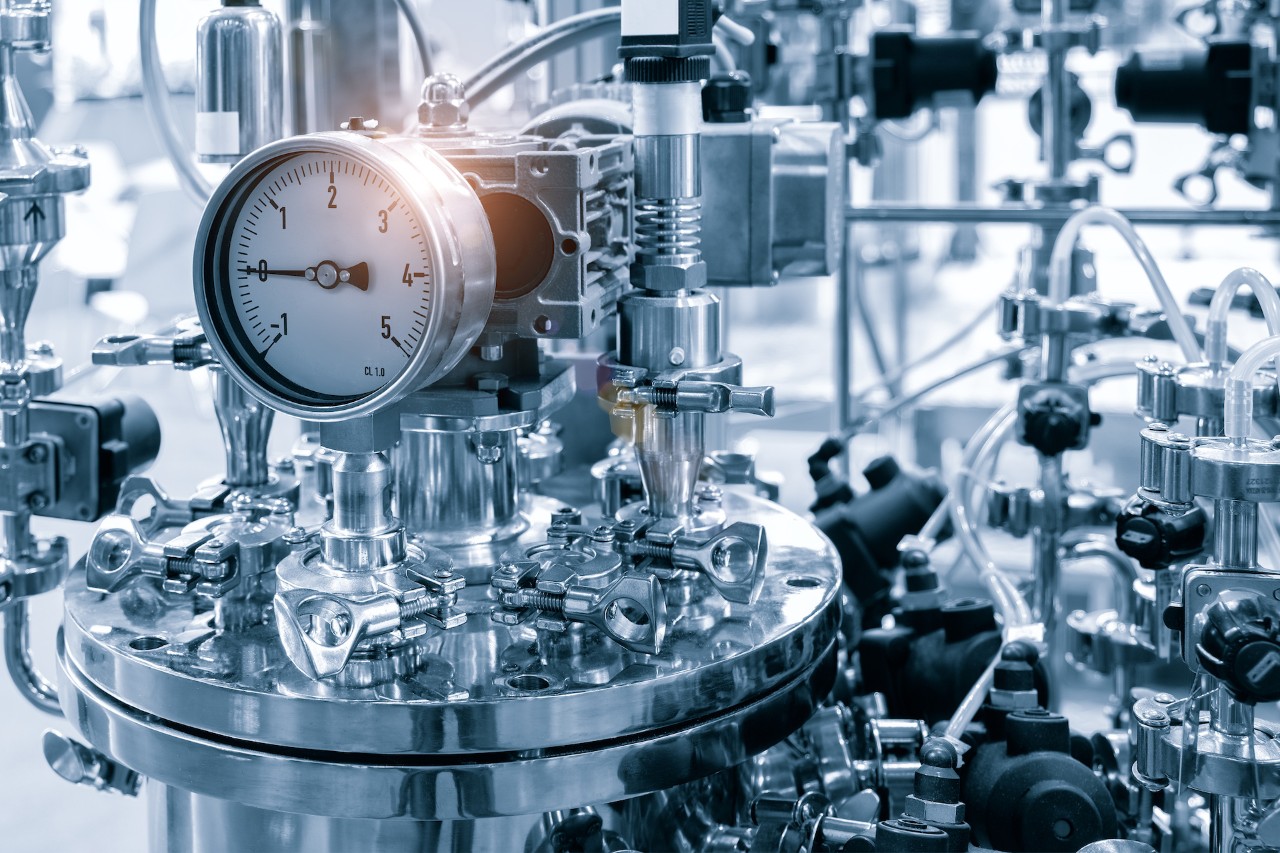

- Flow through flow unit, based on industry tested well established InsightMR design, withstands pressure up to 10 bar

- Adjustable temperature (25 - 60° C), sample and transfer lines. Complete temperature control from vessel to magnet and back

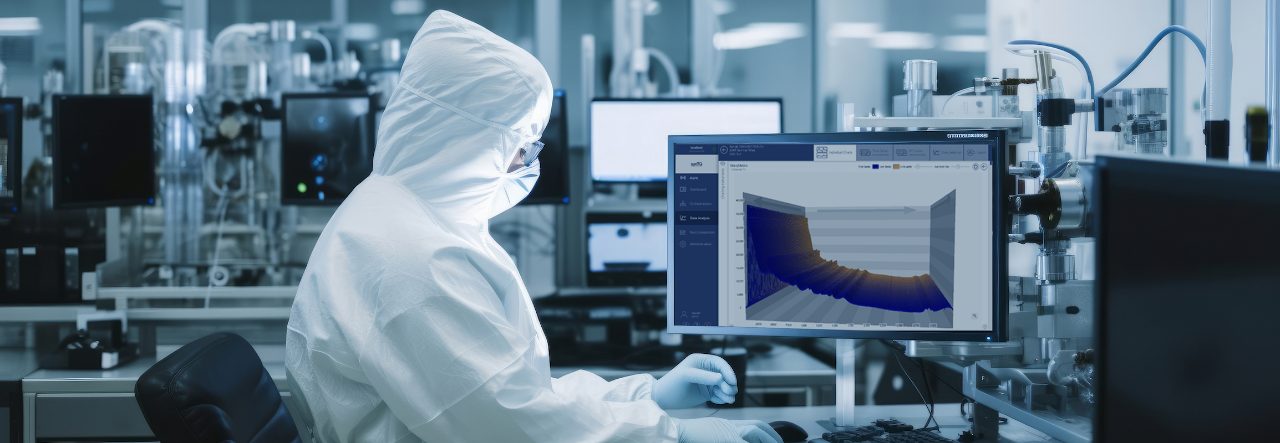

- Automated control of pump and thermostat via synTQ orchestration

- Software interface with on-the-fly reaction experiment adjustments through synTQ optimization

- Seamless data transfer from acquisition to analysis. Automatic visualization of data from NMR and other analytical techniques in synTQ to perform multivariate data analysis

Benefits

- Increased reaction understanding and decreased process optimization time for process chemistry, thanks to real-time NMR analysis in a PAT environment

- Identification and quantification of reaction components in real time (e.g. metabolites in bioproduction media)

- On-the-fly quantitative build-up curves and NMR capability of calibrating other analytical techniques (IR, Raman or LC)

- Determination of critical process parameters for both batch and flow chemistry scenarios

- Multivariate data real-time orchestration to provide unprecedented process information

- Compact footprint, designed for routine R&D and pilot plant

- Structural information for reagents, (bi)products, intermediates and products

- Conversion, in-situ reaction yield and reaction kinetics in real time

Software

Seamless Software Integration

- NMR control: synTQ orchestrates the experiment through its NMR adapter and remote control of TopSpin

- Pump/thermostat control: synTQ regulates pump and thermostat through a dedicated adapter, with potential interaction with the NMR adapter for stop flow capability

- Data analysis: Data are visualized in synTQ, with possibility of live experiment optimization

- Expansion capabilities: synTQ interfaces with several platforms: reactors, sensors, other analytical devices and data processing software. This makes the Fourier PAT the ideal solution for a PAT start-up lab.

Testimonials

Dr. Andrei Bunescu, IPSOPHENE, Toulouse, France

As a powerful tool in Process Analytical Technology (PAT), NMR spectroscopy offers unmatched advantages for real-time process monitoring and control. One of its greatest strengths is that it provides easy-to-interpret data, making it accessible to both experts and non-experts. Additionally, NMR is a non-destructive method, allowing continuous analysis without altering the sample, which is crucial for maintaining process integrity.

Unlike many other analytical techniques, NMR is inherently quantitative and requires no complex calibrations, significantly reducing setup time and complexity. Its high dynamic range of concentration detection ensures precise measurements across various process conditions. Moreover, it is perfectly adapted for small molecule analysis and, importantly, for the analysis of complex mixtures rather than just pure compounds, making it ideal for real-world process applications.

The advent of Benchtop NMR has further expanded the applicability of NMR in PAT by offering a compact, cost-effective, and user-friendly alternative to traditional high-field instruments. These systems maintain the key advantages of NMR while requiring minimal infrastructure, enabling deployment directly on the production floor for on-site, real-time monitoring.

Beyond its analytical capabilities, NMR is an asset for process follow-up, providing real-time insights that enhance process understanding and optimization. Thanks to its robustness and reliability, it has become an indispensable technique for ensuring efficiency, quality, and consistency in modern manufacturing processes.