Glass in Industry

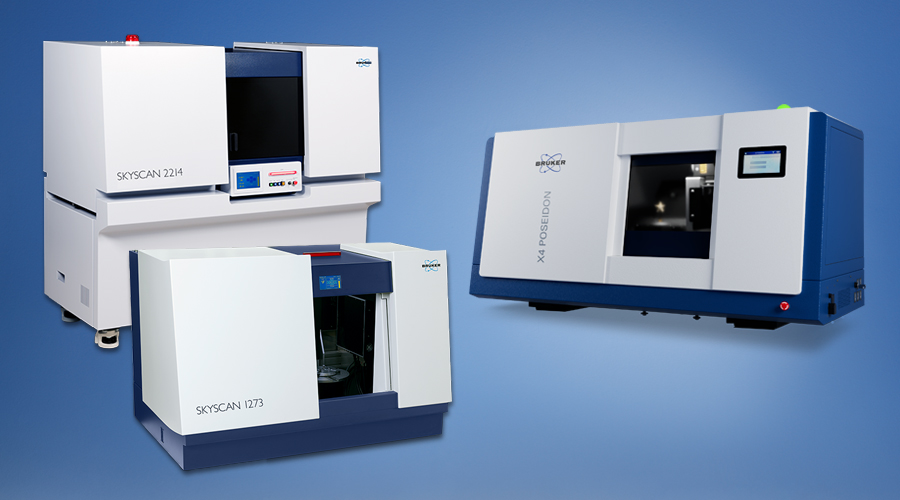

In order to meet the requirements of its later use different types of material are mixed or dissolved in the raw glass. This process as well as the raw material analysis can be monitored by X-ray fluorescence analysis (XRF), depending on elements and concentration ranges either by EDXRF S2 PUMA or WDXRF S6 JAGUAR.

To perform a non-destructive analysis of glass in its final state or metallic coatings, or to perform an analysis of the spatial distribution of particular elements of interest, the micro-XRF technology such as the M4 TORNADO, the M4 TORNADO PLUS or the QUANTAX Micro-XRF for SEM are well suited analysis methods.

If higher spatial resolution is required, scanning and transmission electron microscopes (SEM and TEM) provide extremely high resolution and the opportunity to use the Bruker QUANTAX system to perform energy dispersive spectrometry (EDS) for inorganic material analysis. Using the wavelength-dispersive spectrometer QUANTAX WDS, challenging materials in the low energy or light element range can be better determined due to its excellent energy resolution and light element sensitivity. Using the SEM based QUANTAX EBSD (electron backscattered diffraction) system, crystal orientation maps can be acquired to understand the crystallography and phase boundaries, and study deformations in materials.

Exactly the fundamental property of the ‘glassy state’ anticipates that traditional X-ray diffraction (XRD) provides sensible structure information – glass does not have a long-range order as present in crystalline material. µ-XRD with the D8 DISCOVER can help to characterize spurious inclusions found in glass because they are typically formed by crystalline material.

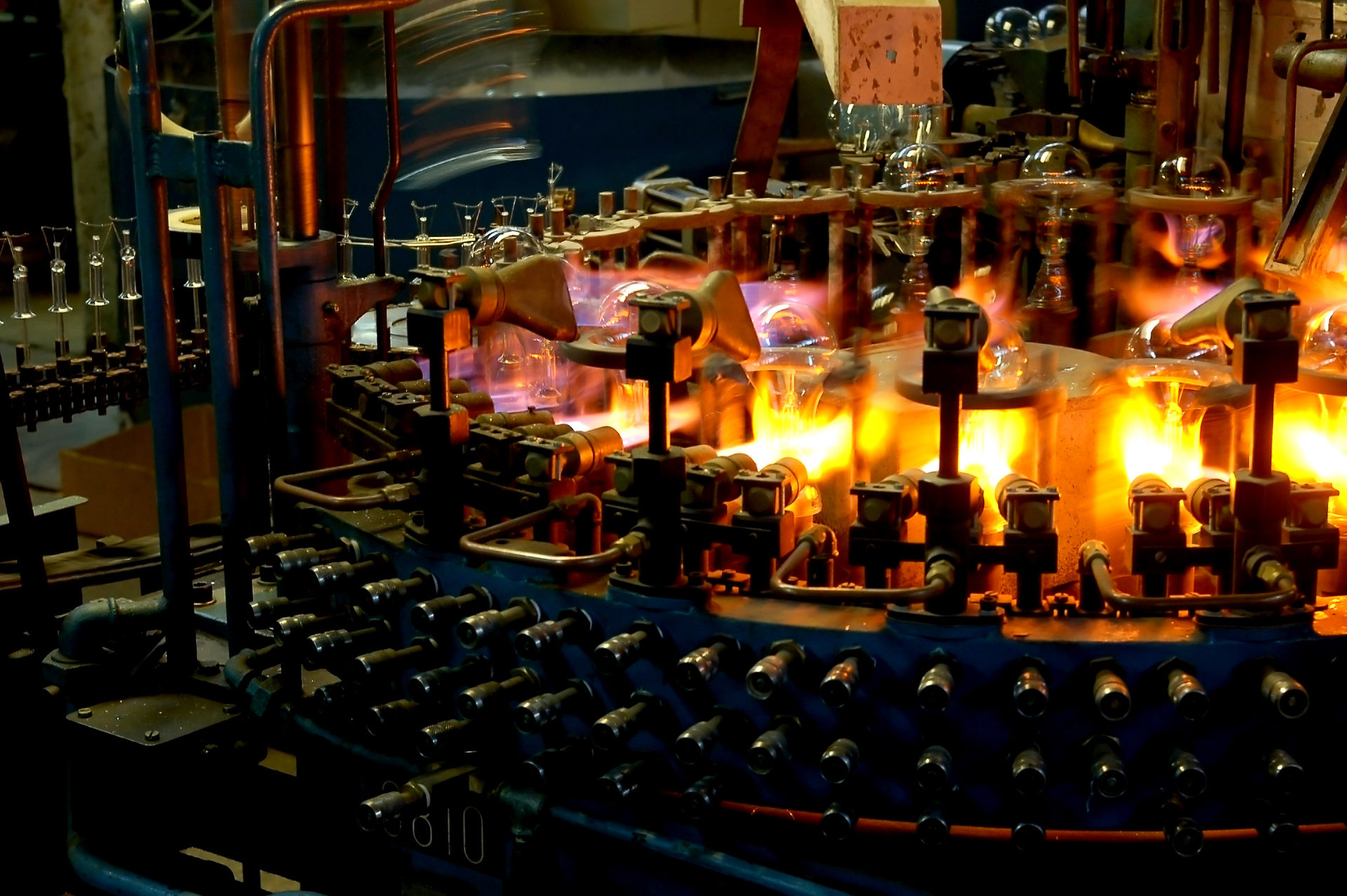

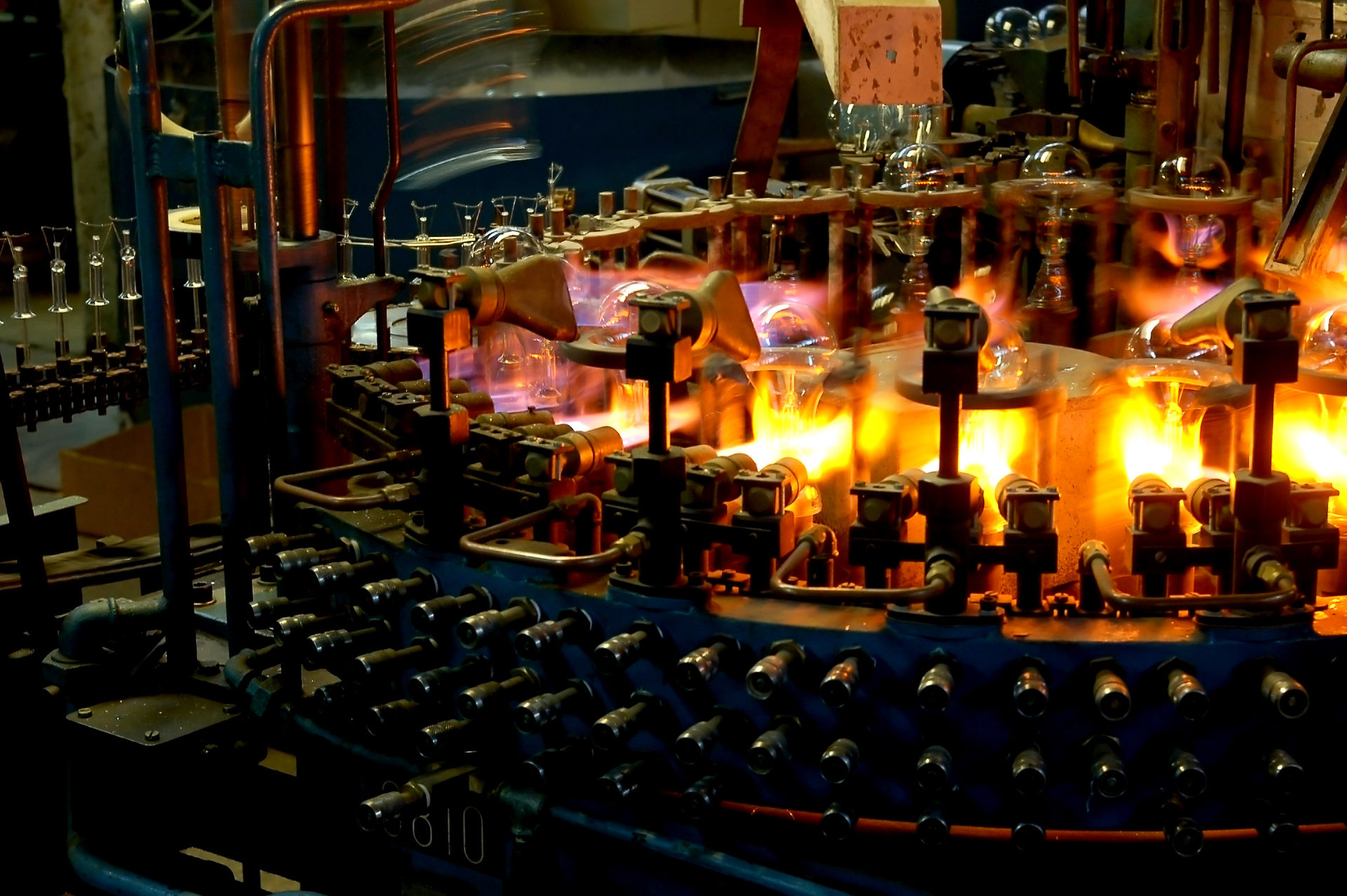

Frequently raw glass as well as metal is coated for various reasons. The coating might be anticorrosive, harden the surface, may reflect thermal radiation or any other type of light, or simply ennoble the underlying material.

Grazing incidence X-ray diffraction (GID) with the D8 ADVANCE helps to determine unambiguously the crystalline composition of the coating. X-ray Reflectometry (XRR) and micro-XRF technologies enable non-destructive determination of the layer thickness, even for sub-surfaces layers.