Espectrómetros Micro-XRF

Gama única de espectrómetros de fluorescencia de rayos X para el análisis de elementos

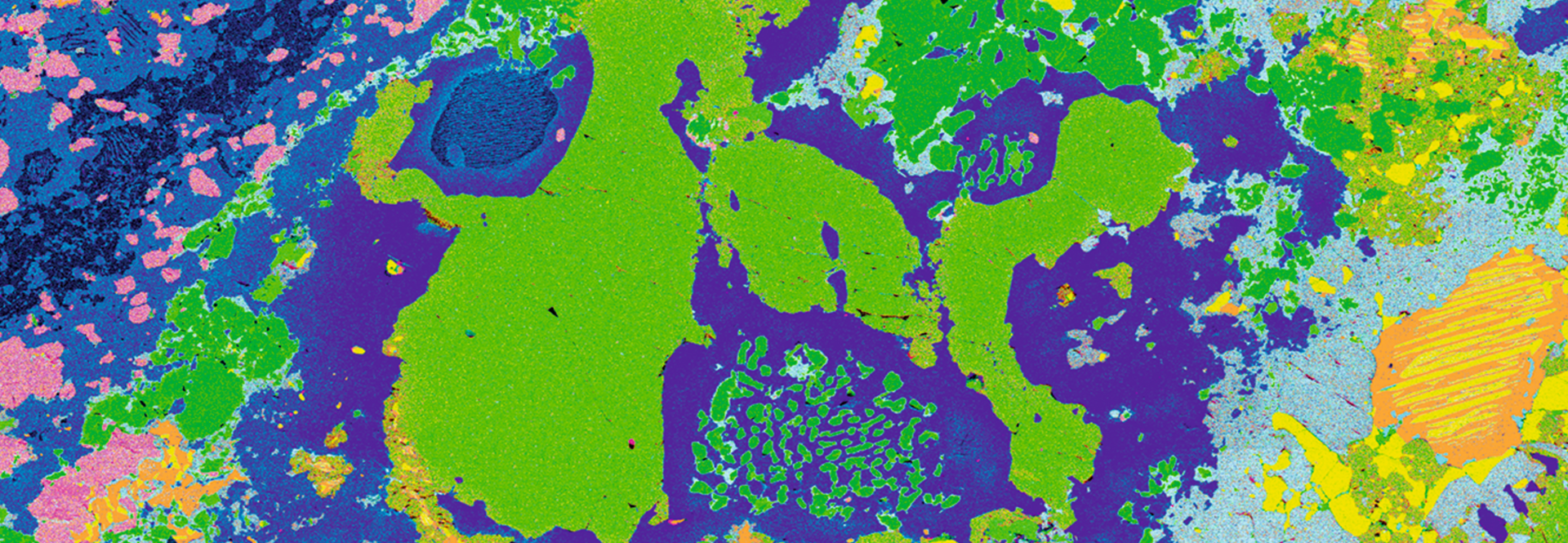

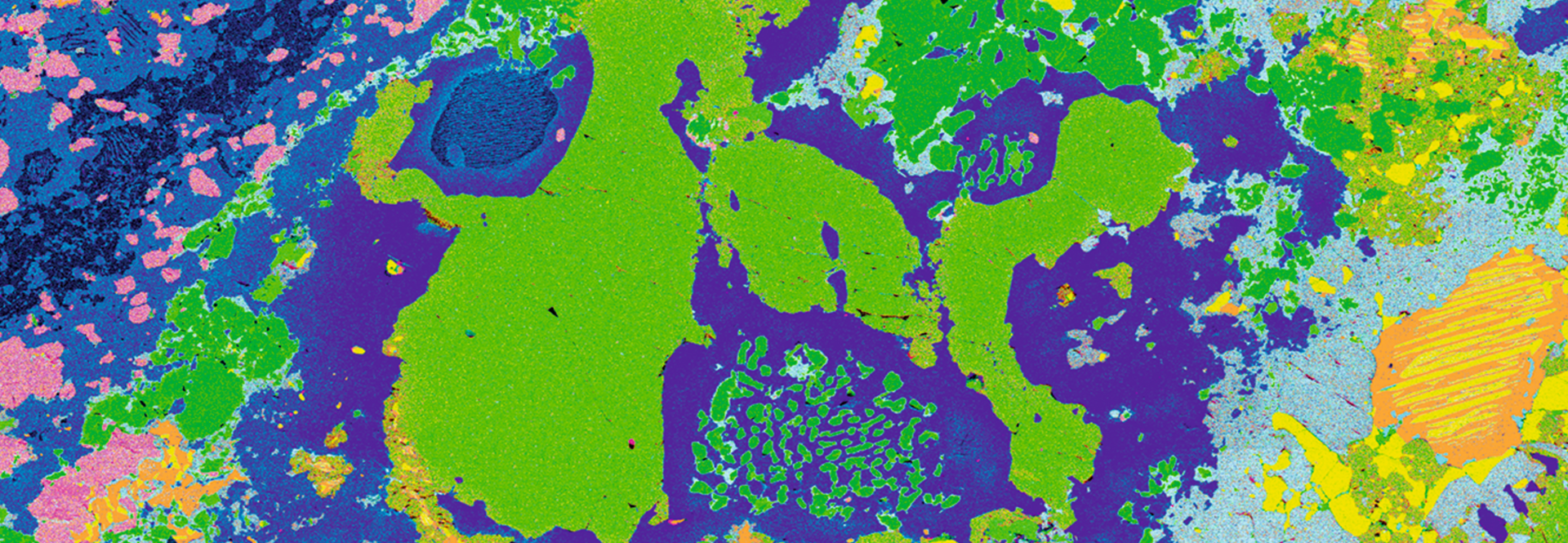

La espectrometría de microfluorescencia de rayos X es un método ideal para el análisis de elementos en muestras no homogéneas o de forma irregular, así como muestras pequeñas o incluso inclusiones.