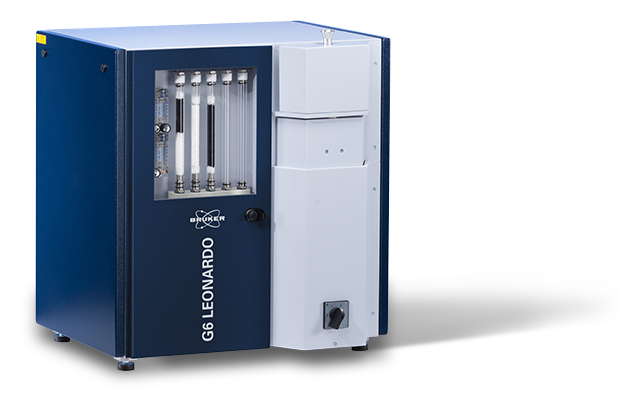

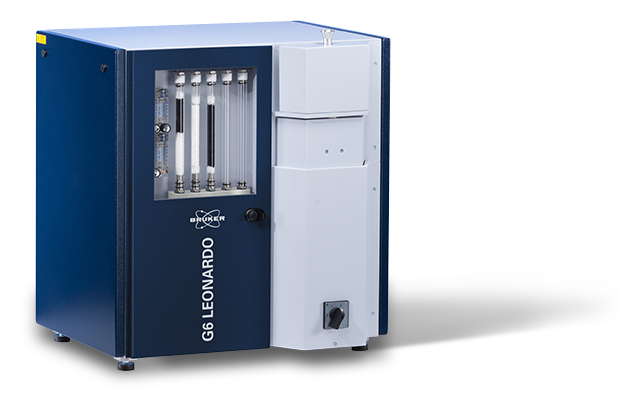

G6 LEONARDO

ECOnomic Quality & Process Control for O/N/H

Simplicity @ its best

SampleCare™ & FusionControl ensure reliable results

High-precision, easy-to-use and robust Inert Gas Fusion analyzer

ppb (ng/g)

Limit of Detection for Hydrogen and Nitrogen

The high-end thermal conductivity detector used for hydrogen and nitrogen analysis allows detection limits in a sub-ppm range (based on 1g sample mass)

> 3000 °C

Achievable by the advanced electrode furnace for refractory samples

The water cooled electrode furnace is equipped with FusionControl for precise temperature control. SampleCare™ includes an integrated maintenance-free sample port shielding the sample from undesirable heat.

0 l/min

Consumption of compressed air

The lower electrode movement by EZDrive eliminates the need for additonal working gases, ensures an ideal contact between crucible and electrodes to provides enhanced safety and reliability.

G6 LEONARDO - ECOnomic Qualiy and Process Control by Inert Gas Fusion

Electrode Furnace with SampleCare and FusionControl

The three non-metals Oxygen (O), Nitrogen (N) and Hydrogen (H) determine the quality, service life and mechanical properties of all metallic materials. Unlike metallic alloy components, the amount of O, N and H sometimes changes considerably along the entire process chain, from the production of raw materials to the completion of the finished product. Even when present in trace amounts, O, N and H have a very critical effect on the material properties.

The G6 LEONARDO is based on the inert gas fusion (IGF), which involves fusion of the sample material in a graphite crucible at high temperatures. This principle is also commonly termed gas fusion analysis (GFA) or melt extraction (ME) since the total oxygen, nitrogen and hydrogen is extracted by an inert carrier gas when the sample melts.

The G6 LEONARDO is based on the inert gas fusion (IGF), which involves fusion of the sample material in a graphite crucible at high temperatures. This principle is also commonly termed gas fusion analysis (GFA) or melt extraction (ME) since the total oxygen, nitrogen and hydrogen is extracted by an inert carrier gas when the sample melts.

The Smart Molecule Sequence™ guarantees trustworthy results

The aim of an IGF analysis is to determine the sample content of the light elements O, N and H in the trace range with absolute accuracy. That is why our G6 LEONARDO applies the Smart Molecule Sequence™ and measures the gases emitted by the sample directly, absolutely unchanged, 1:1, with proven scientific principles for trustworthy results. It also allows oxygen determination without additional chemicals, and usage of argon carrier gas instead of helium ensuring high reliability and low cost of ownership.

The aim of an IGF analysis is to determine the sample content of the light elements O, N and H in the trace range with absolute accuracy. That is why our G6 LEONARDO applies the Smart Molecule Sequence™ and measures the gases emitted by the sample directly, absolutely unchanged, 1:1, with proven scientific principles for trustworthy results. It also allows oxygen determination without additional chemicals, and usage of argon carrier gas instead of helium ensuring high reliability and low cost of ownership.

Key Benefits:

- FusionControl™: Ongoing contact free temperature measurement of the sample

- SampleCare™ for IGF analysis consisting of EZDrive, water cooled sample port, high capacity dust trap, followed by efficient in-line particle filtering

- Smart Molecule Sequence™: Direct and unadulterated measurements of all emitted gases by state of the art detectors with reference channels.

- FUSION.ELEMENTS™: Future-save easy to use software based on Bruker's Alaska platform

G6 LEONARDO - high-precision, compact, easy to maintain O/N/H analyzer

Dual channel TCD with intergrated heat exchanger

Lower electrode with EZDrive

Calibration wizard of FUSION.ELEMENTS

Method wizard of FUSION.ELEMENTS

Optimized with user-friendly features

SampleCareTM, Smart Molecule SequenceTM including FusionControl and ready-to-use precalibrated methods for many industrial standard applications make the G6 LEONARDO a great choice for process and quality control in primary metal manufacturing and processing, ceramics, and powder metallurgical processes.

G6 LEONARDO Specifications

| Specification | Benefit | ||

Samples Sample Types | Inorganic, dry, any form or shape | Flexibility | |

| Sample Dimensions | 8 x 8 mm cross section (pieces, chips, pins, granules), different sample ports available for special applications | Wide variety of sample materials | |

Detectors OxygenNitrogen and Hydrogen | Nondispersive IR absorption of CO, no moving parts, multiple range detectors with reference beam and on-board linearization Thermal conductivity detector with reference channel and adjustable gain amplifier | Reliable, maintenace-free performance without drift Reliable, adjustable ranges, drift free | |

| Furnace | Water-cooled Electrode Furnace with FusionControl | Solid high temperature operation for refractories, precise temperature control | |

SampleCare™ EZDriveSample Port Particle Filtering | Lower electrode movement by reliable electronic motion module Rotating sample port integrated into water cooled furnace block High-capacity dust trap followed by in-line particle filtering | Robust, cost-saving operation without working gas. Automatic, torque limited readjustment ensures ideal crucible:electrode contact and safety for crucible, furnace and operator. Shields sensitive samples from heat input and hydrogen losses before analysis. Allows capsule-free measurement of grains without jamming. Stable analytical results with reduced maintenance and component protection | |

| Cooling Water | 4 l/min at 3 bar supply pressure | Fits on every usual tap water line, tap, water-saving design with solenoid valve, chiller also possible | |

| Carrier Gas | Ar (O, N), He (O, N), N2 (H) each 99.995 % purity (99.9990 % for trace analysis) | Flexible carrier gas choice without compromises | |

| Noise Emission | < 55 dB(A) peak | Enjoy the silence | |

| Calibration | Single and multipoint calibration, advanced weighting algorithm with error bars and range merging | Easy simultaneous calibration of all ranges with confidence | |

| Reagents |

| ||

| Power Supply | 400 - 480 VAC (± 10 %), 50-60 Hz, 32 A, 7 kVA, 1 Phase plus N or 2 Phase, grounding wire 230 VAC (± 10 %), 50-60 Hz, 64 A, 7 kVA available as option | Compatible to worldwide power and current configurations | |

| Models Available | Single or dual element O, N, H, ON, OH | Ideal tool for process and quality control | |

| Dimensions and Weight | 71 x 66 x 78 cm (W x D x H), ~145 kg | Compact form, easy to maintain | |

| *) Depending on configuration |

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)